Satin alcyonne waterproof fabric with multiangle visual color changing performance and preparation process thereof

A waterproof fabric and preparation process technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of unpleasant feeling, lack of three-dimensional sense, single fiber variety, etc., and achieve bright color, rich layers, color The effect of high fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

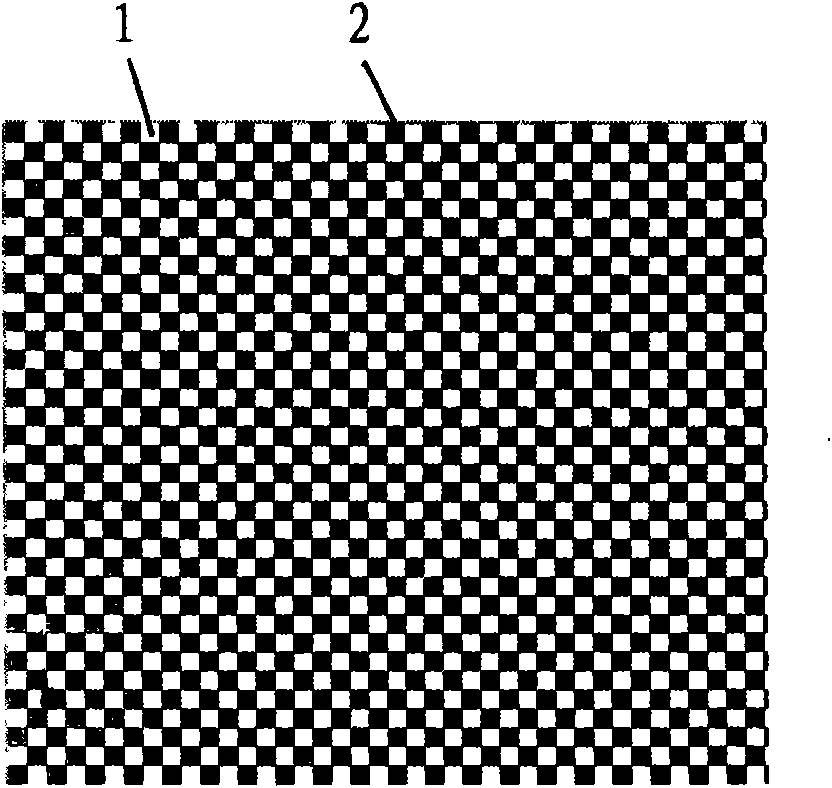

[0023] Depend on figure 1 Represented is embodiment one of the present invention, and it comprises radial yarn 1, weft yarn 2, and its radial yarn 1 and weft yarn 2 are dyed acrylic fiber yarn with red color after fabric weaving respectively It is composed of spandex yarn with blue color; its structure is plain weave structure; it has a waterproof coating surface; the number of radial yarns is 35 / cm, and the number of weft yarns is 40 / cm. The density is 190T.

[0024] Its preparation process is as follows:

[0025] 1) Fabric weaving: the radial yarn 1 of the fabric uses undyed acrylic yarn, the weft yarn 2 adopts undyed spandex yarn, and the radial yarn 1 and the weft yarn 2 use For plain weave, 35 yarns / cm are used for 1 radial yarn, 40 yarns / cm are used for 2 weft yarns, and the fabric density is 190T.

[0026] 2) Dyeing process: use acid dyes and cationic dyes in the same bath for dyeing, acid dyes are used to dye spandex fibers, and cationic dyes are used to dye acrylic...

Embodiment 2

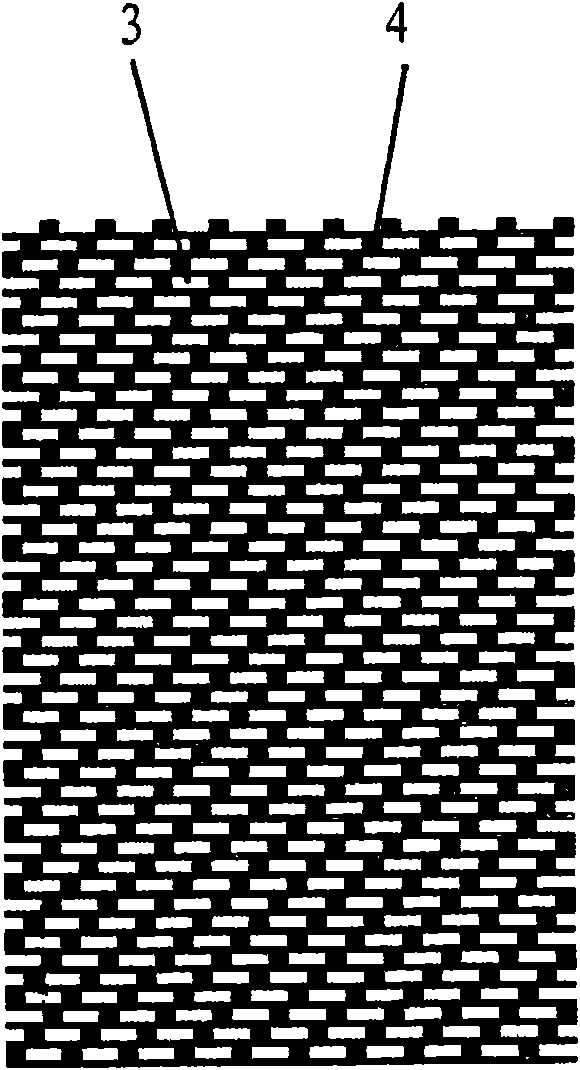

[0043] Depend on figure 2 Represented is embodiment two of the present invention, and it comprises radial yarn 3, weft yarn 4, and its radial yarn 3 and weft yarn 4 are respectively by the acrylic fiber yarn of red color after being woven by fabric Composed of spandex yarn with yellow color; its structure is twill weave structure; on the fabric printing pattern, that is, the surface layer has a waterproof coating surface; the number of radial yarns is 45 / cm, and the number of weft yarns is 4 It is 30 threads / cm, and the fabric density is still 190T.

[0044] Its preparation process is as follows:

[0045] 1) Weaving of the fabric: the radial yarn 3 of the fabric still uses undyed acrylic yarn, the weft yarn 4 adopts undyed spandex yarn, and the radial yarn 3 and the weft yarn 4 adopt twill weave For the structure, 45 yarns / cm are used for 3 radial yarns, and 30 yarns / cm are used for 4 weft yarns, and the fabric density is still 190T.

[0046]2) Printing process: the fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fabric density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com