Construction method of cylindrical slurry core pile for retaining and protecting foundation pit

A technology of foundation pit support and construction method, which is applied in basic structure engineering, excavation, sheet pile wall and other directions, can solve the problems of long construction period, many construction equipment, and high engineering cost, and achieves less construction equipment, fewer operators, The effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

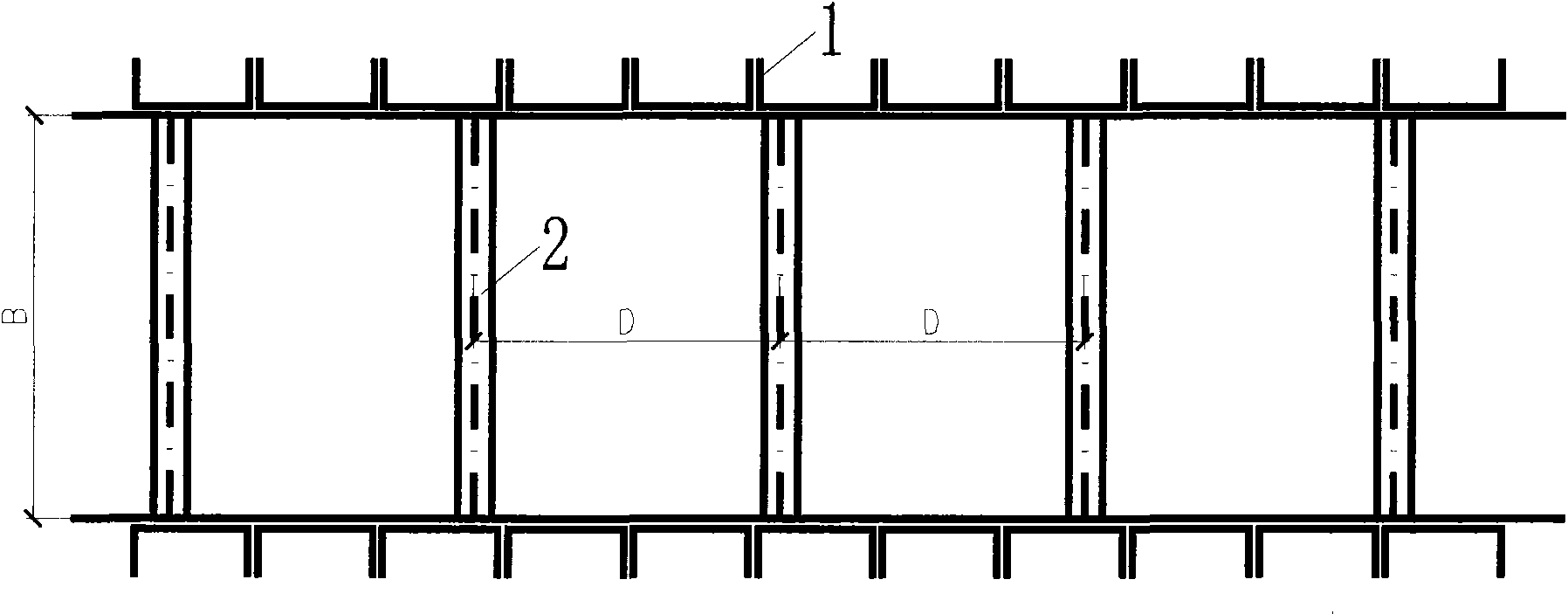

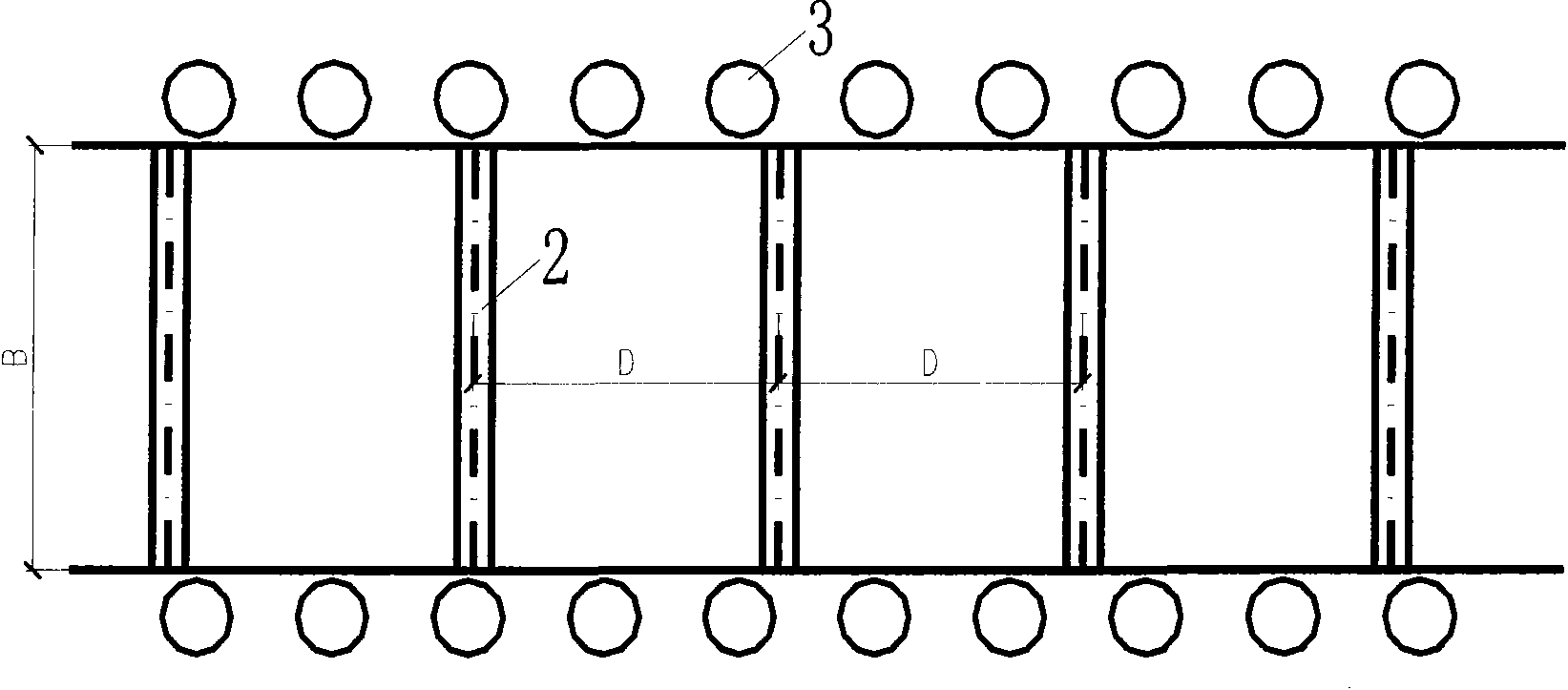

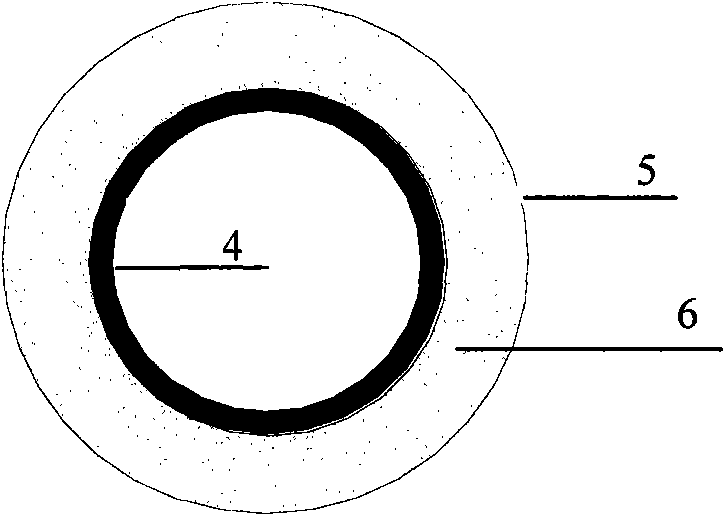

[0034] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0035] Example 1 For the construction of the foundation pit of an old cohesive soil pipeline, the distance between the centers of the cylinder slurry core piles is 500mm, the depth of the foundation pit is 6.0m, and the height of the cylinder slurry core piles is 9.0m.

[0036] 1) Level the site, remove ground and underground obstacles, locate pile holes, and place pile drivers;

[0037] 2) For old cohesive soil, dry drilling is used to drill holes, and the hole diameter is generally 250mm;

[0038] 3) When the hole depth reaches the design height, if there is water in the hole, drain the water in the hole, and place the displaced soil 3.0m away from the edge of the hole;

[0039] 4) Use a backhoe or a drilling rig to put the steel pipe core material with a lower end sealing diameter of 210mm-230mm into the drill hole, and use a locator to locate it;

[0040] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com