Micro-power DC-DC power supply and manufacturing method thereof

A DC-DC and micro-power technology, applied in the direction of conversion equipment with intermediate conversion to AC, can solve the problems of high defective rate of finished products, complicated production process, low circuit operating frequency, etc., to improve production efficiency and simplify production Process, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The embodiments of the present invention disclose a micro-power DC-DC power supply and a manufacturing method thereof. In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

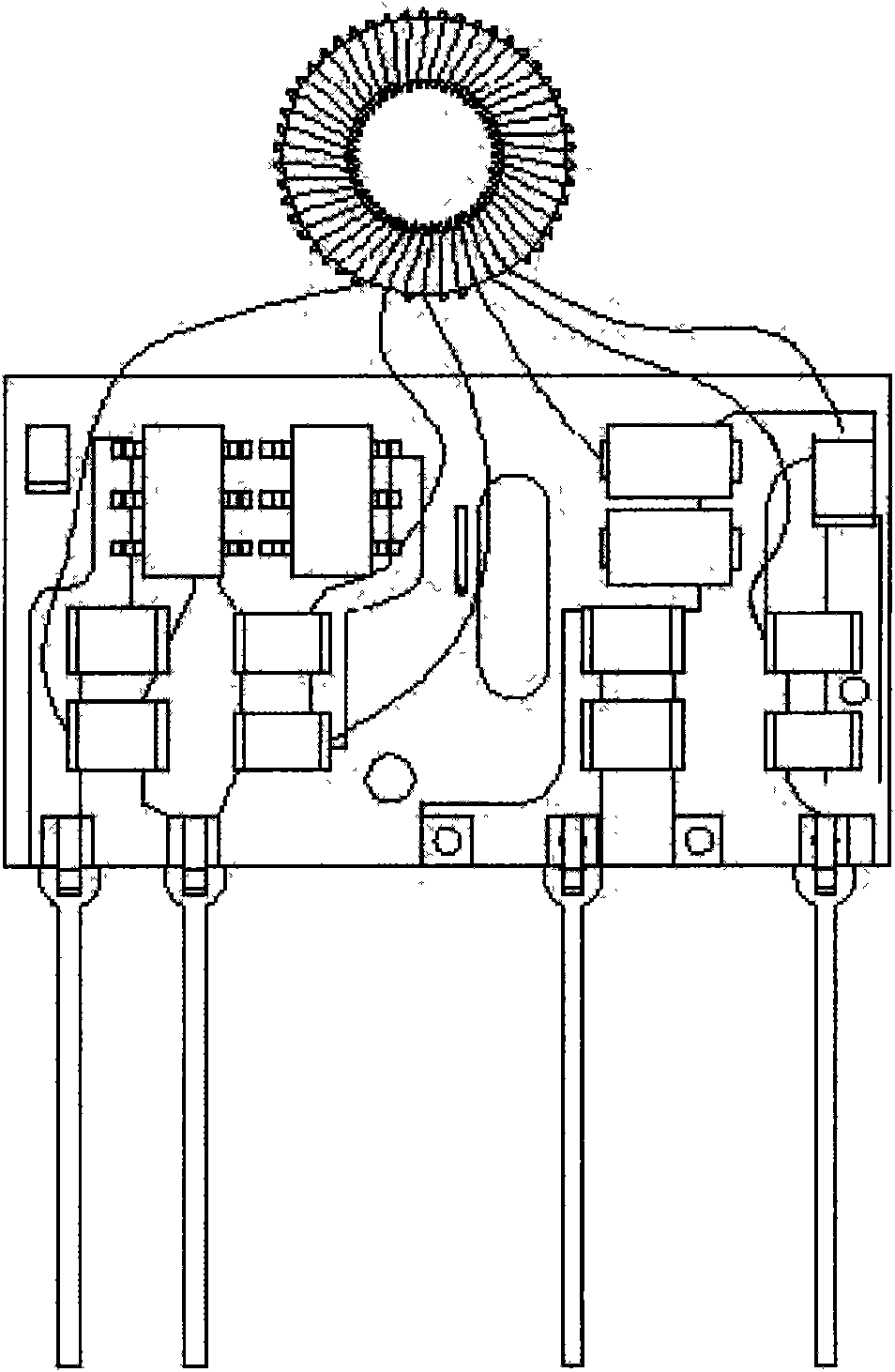

[0044] Figure 4 It is a structural diagram based on an embodiment of the device provided by the present invention.

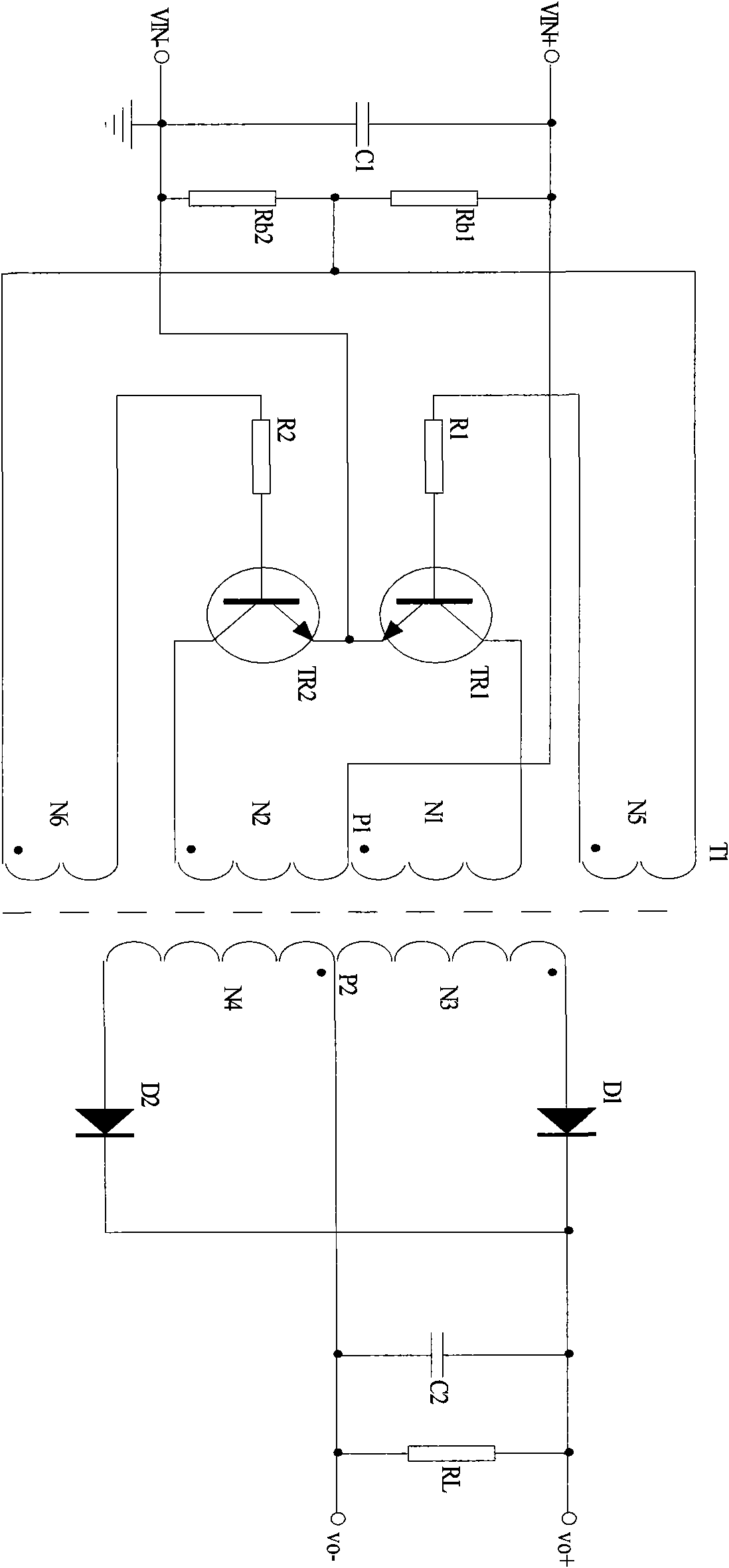

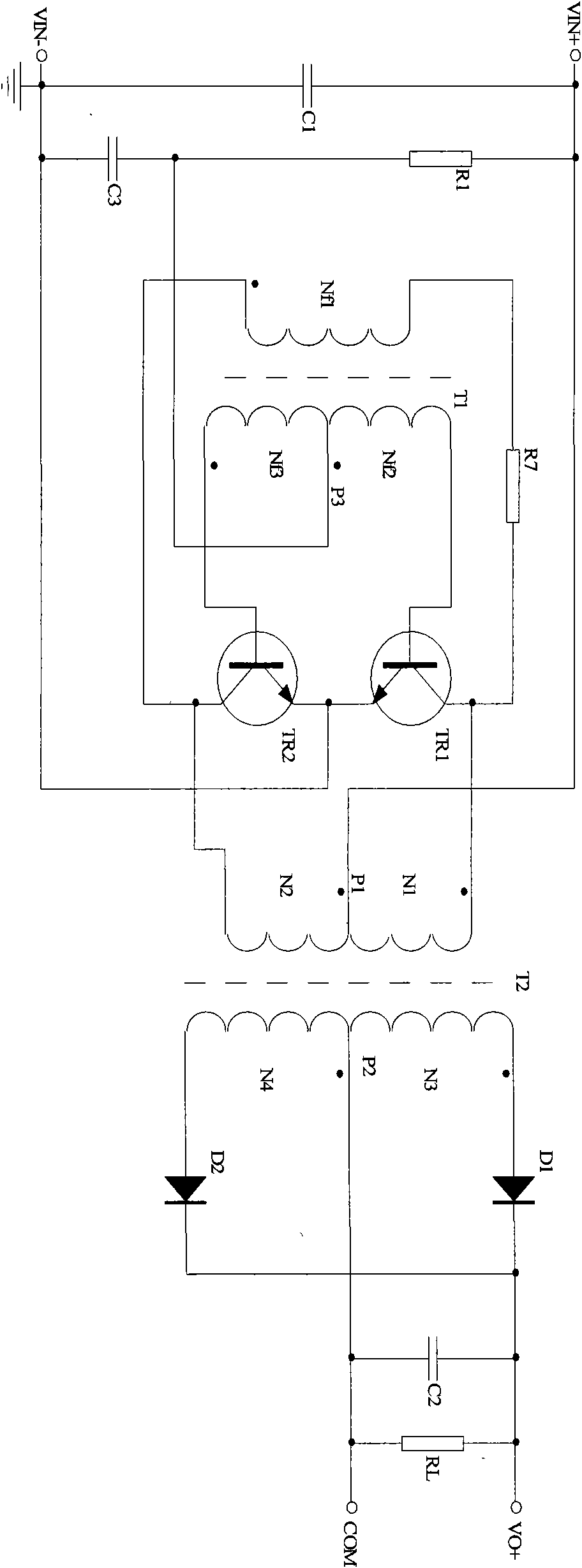

[0045] The micro-power DC-DC power supply provided by an embodiment of the present invention includes a drive control circuit, a push-pull conversion circuit, a power output transformer, and an output rectifier circuit.

[0046] The drive control circuit receives the input voltage and generates two sets of pulse width modulation (PWM) drive waveforms with the same amplitude and a phase difference of 180°. The PWM drive waveforms are used to drive the push-pull conversion circuit connected to the drive control circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com