Method for manufacturing shell of electronic controller for vehicle

A technology of electronic controller and manufacturing method, which is applied in the direction of manufacturing tools, electrical equipment shell/cabinet/drawer, electrical components, etc. High dimensional accuracy and small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

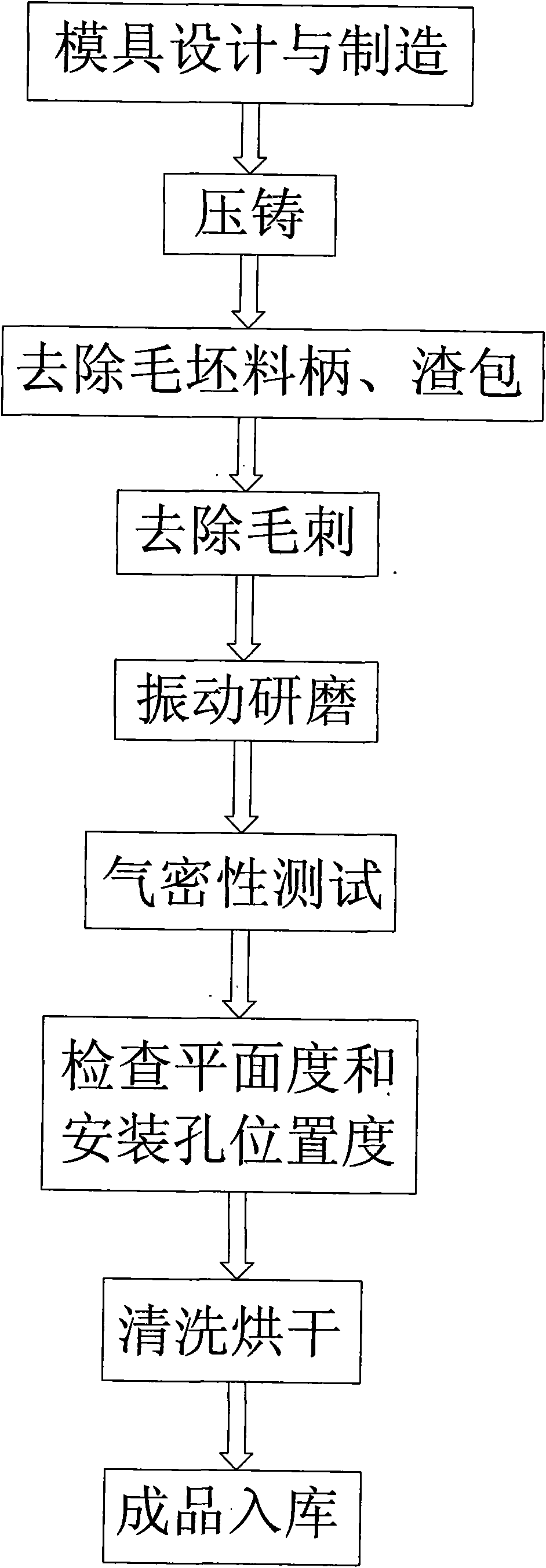

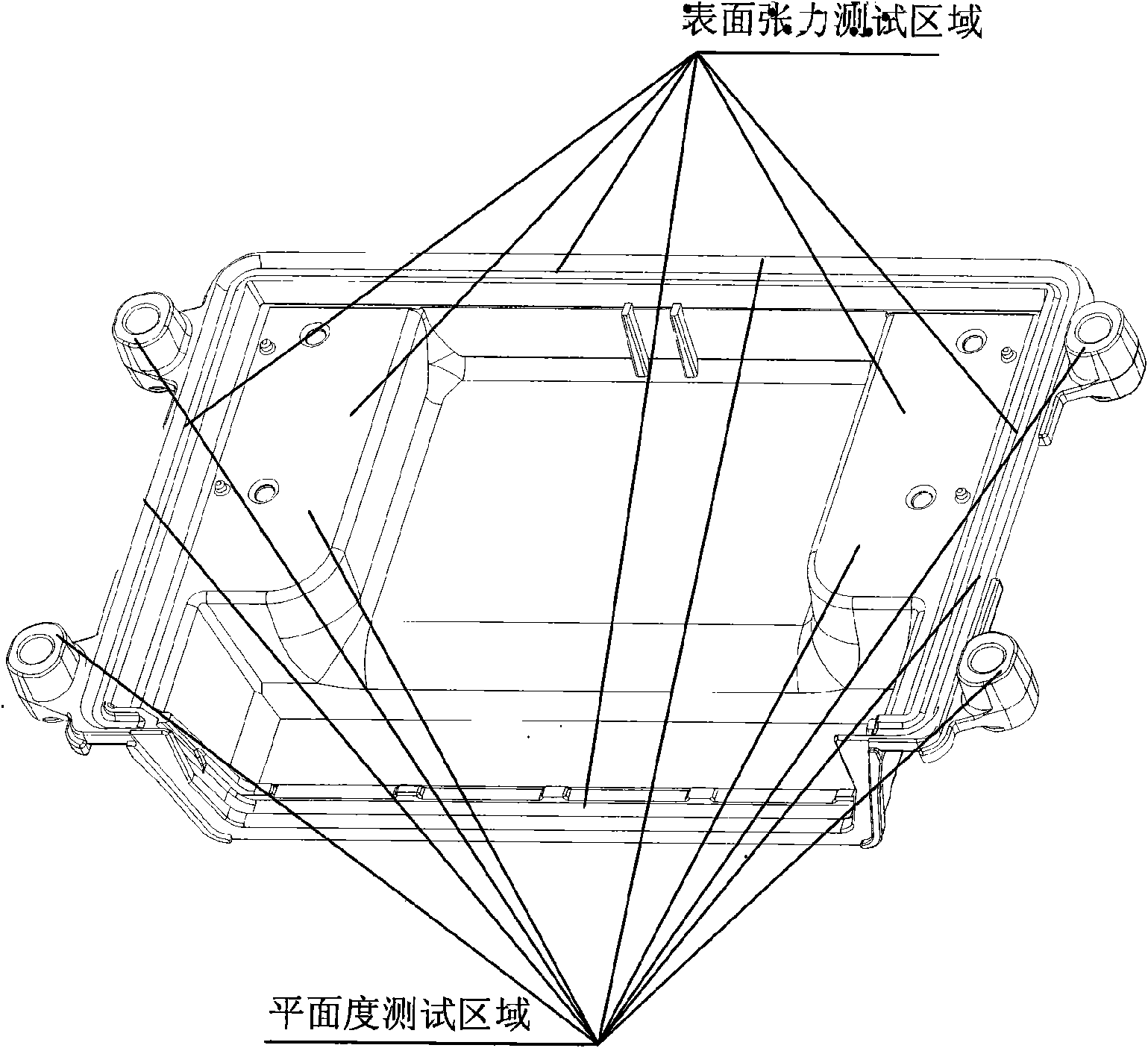

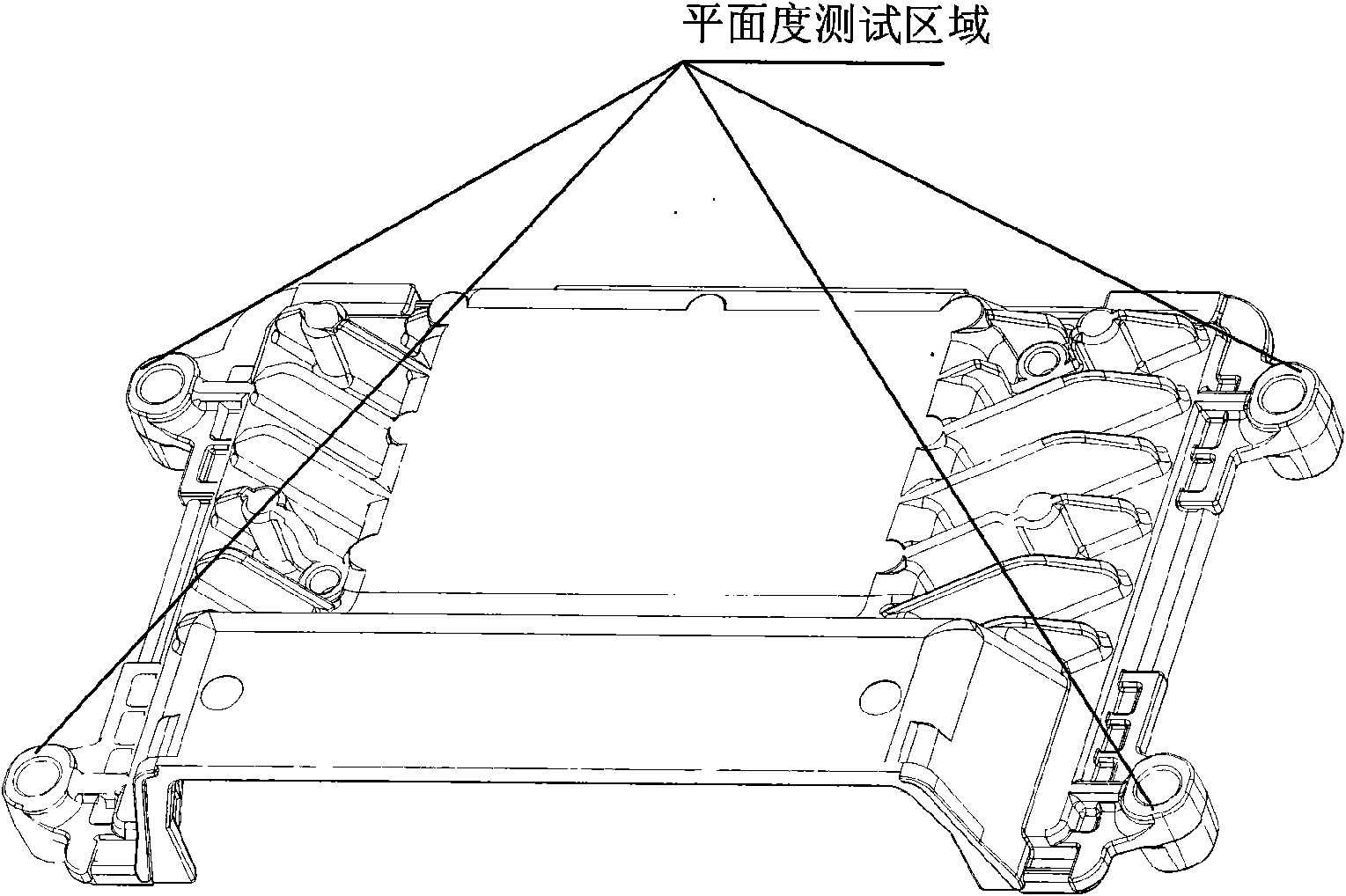

[0027] Such as Figure 1 to Figure 3 As shown, in the embodiment of the present invention, the manufacturing method of the vehicle electronic controller housing includes a mold manufacturing step: making a product mold according to the product requirements with the help of design software; the manufacturing method of the vehicle electronic controller housing also includes the following steps:

[0028] Die-casting steps: choose a suitable die-casting machine, install the product mold into the die-casting machine, select the appropriate die-casting process parameters, use the die-casting machine to fill the product material into the product mold cavity; and obtain the product after the die-casting machine maintains pressure Blank parts; removal of rough material shank and slag bag step: clean the material shank and slag bag attached to the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com