Combination heat sink of closed shell electronic equipment

A technology of electronic equipment and airtight casing is applied in the field of combined heat dissipation of electronic equipment, which can solve the problems of elevated ambient temperature, no maintenance of radiated components, PCB board replacement, inconvenient maintenance, etc., and achieves convenient replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

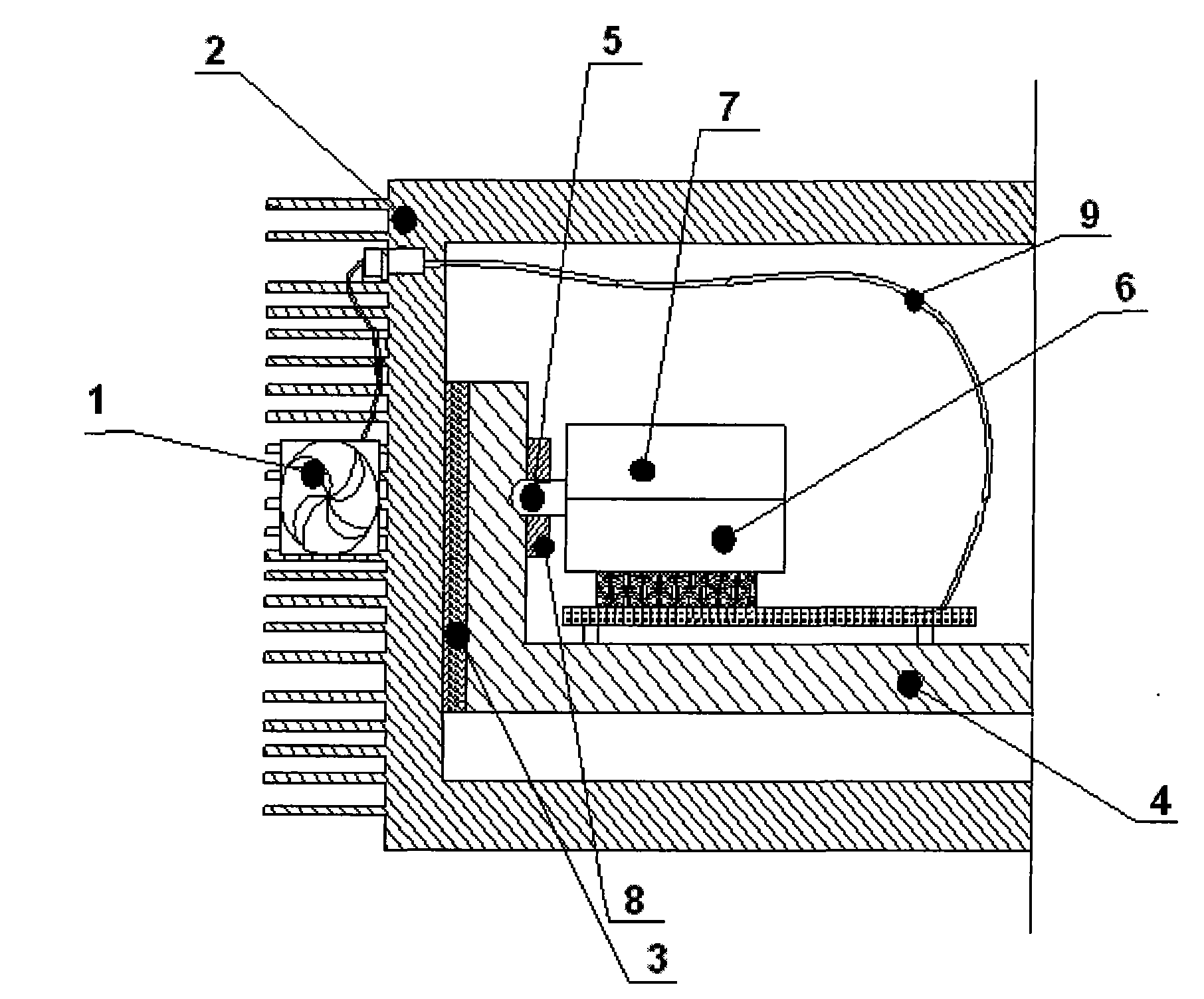

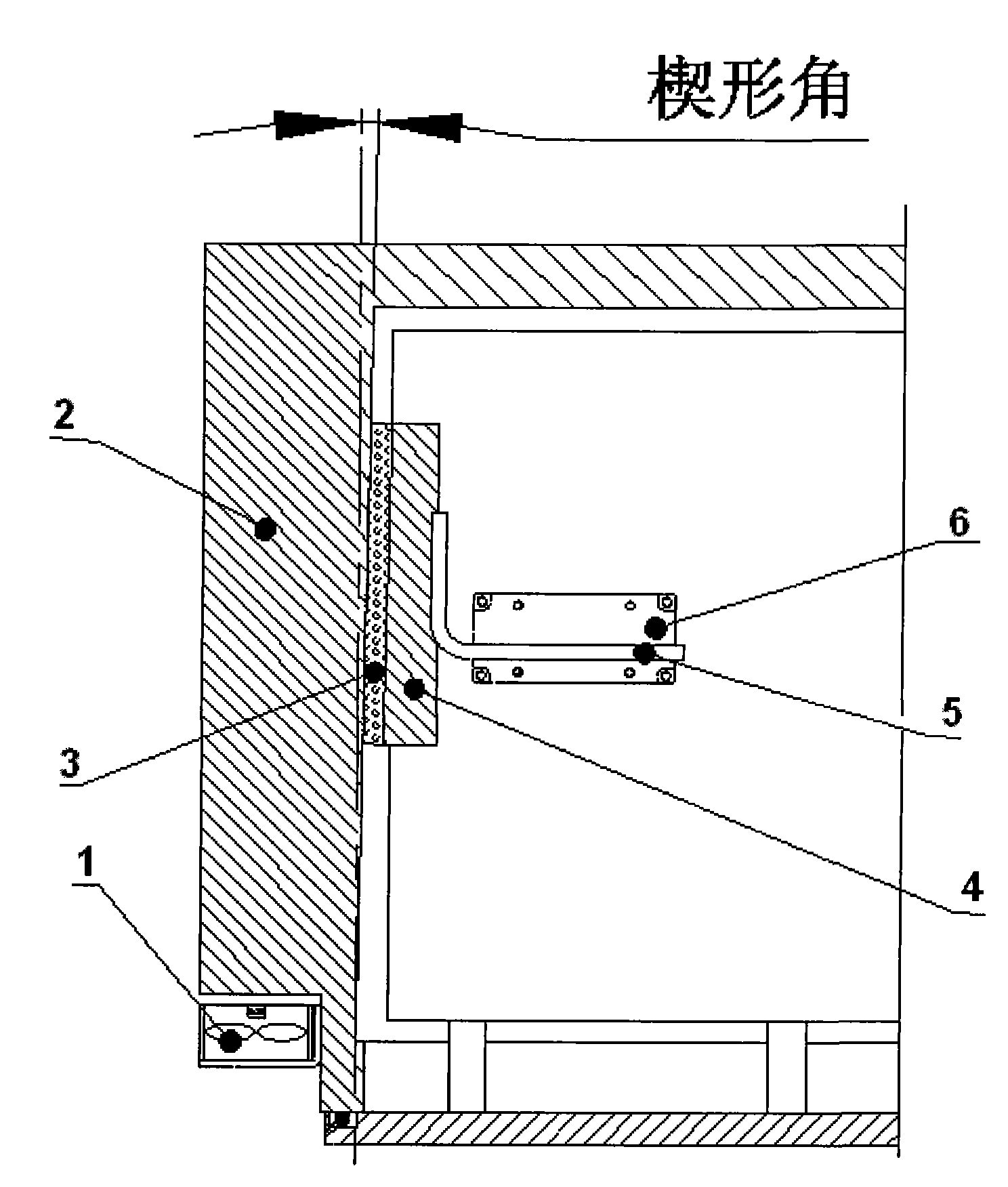

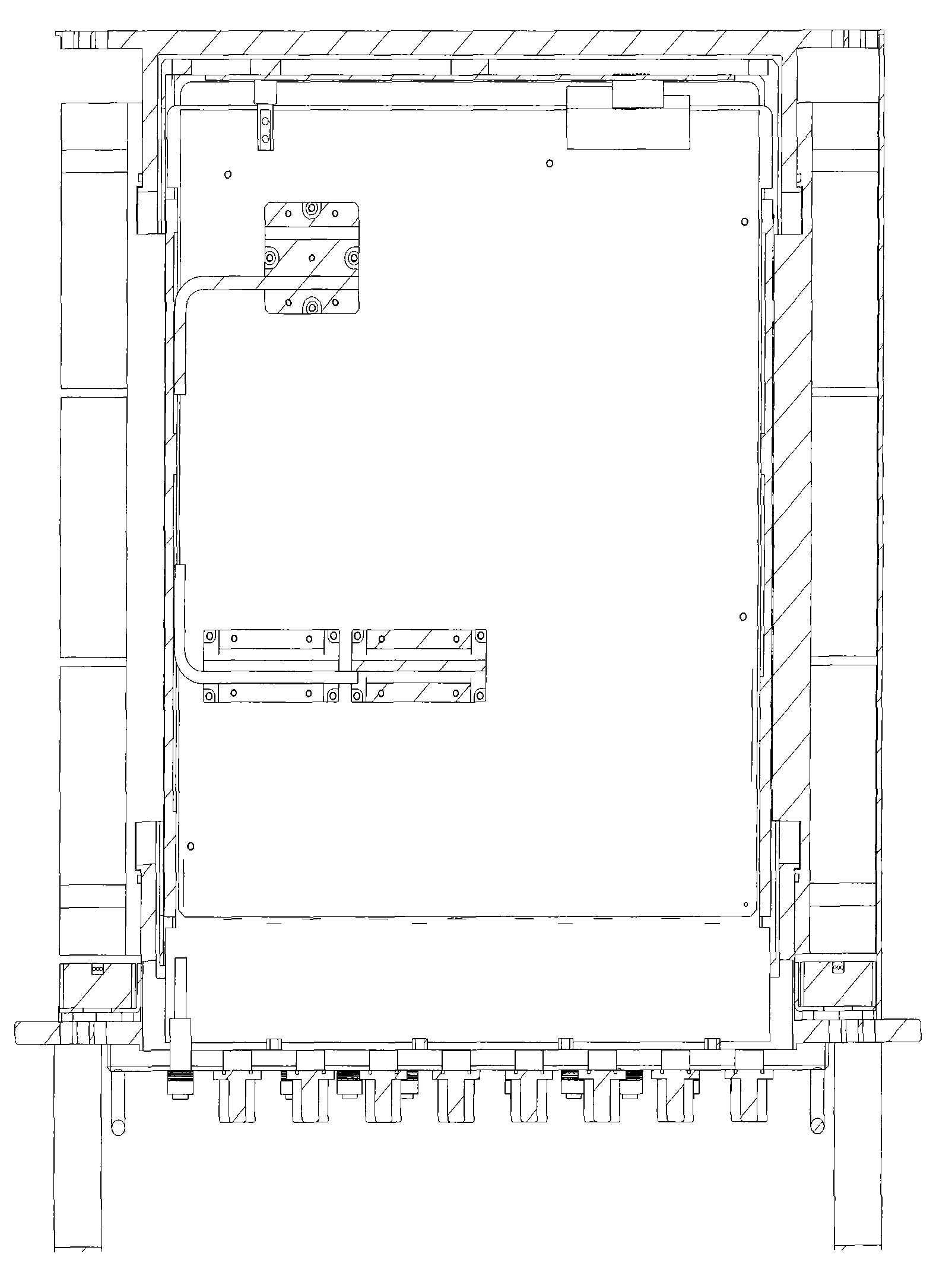

[0017] figure 1 Front view of combined cooling device structure, figure 2 The top view of the structure of the combined heat sink indicates that the combined heat sink consists of a fan 1 , a housing with heat sink 2 , a heat conduction film 3 , a PCB fixing bracket 4 , a heat pipe 5 , and a chip heat conduction plate 6 . The above six components are divided into the internal chip heat conduction component part and the external heat dissipation device part. The internal chip heat conduction component part is composed of heat pipe 5, chip heat conduction plate 6, PCB fixing bracket 4, and heat conduction film 3. Heat pipe fixing plate 8 is fixed. The external cooling device part is composed of a fan 1 and a housing 2 with cooling fins. The PCB fixing bracket 4 , the heat pipe fixing plate 7 at the chip end, the heat pipe fixing plate 8 at the heat dissipation end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com