Combined type hydraulic cylinder design capable of supplying positive and negative bending roller force

A hydraulic cylinder and combined technology, which is applied in metal processing equipment, fluid pressure actuators, metal rolling, etc., can solve the problems of complex hydraulic control system, multiple hydraulic cylinder interfaces, and multiple auxiliary pipelines, and achieve hydraulic pipe The effect of road reduction, reduction of sealing links, reduction of sealing links and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

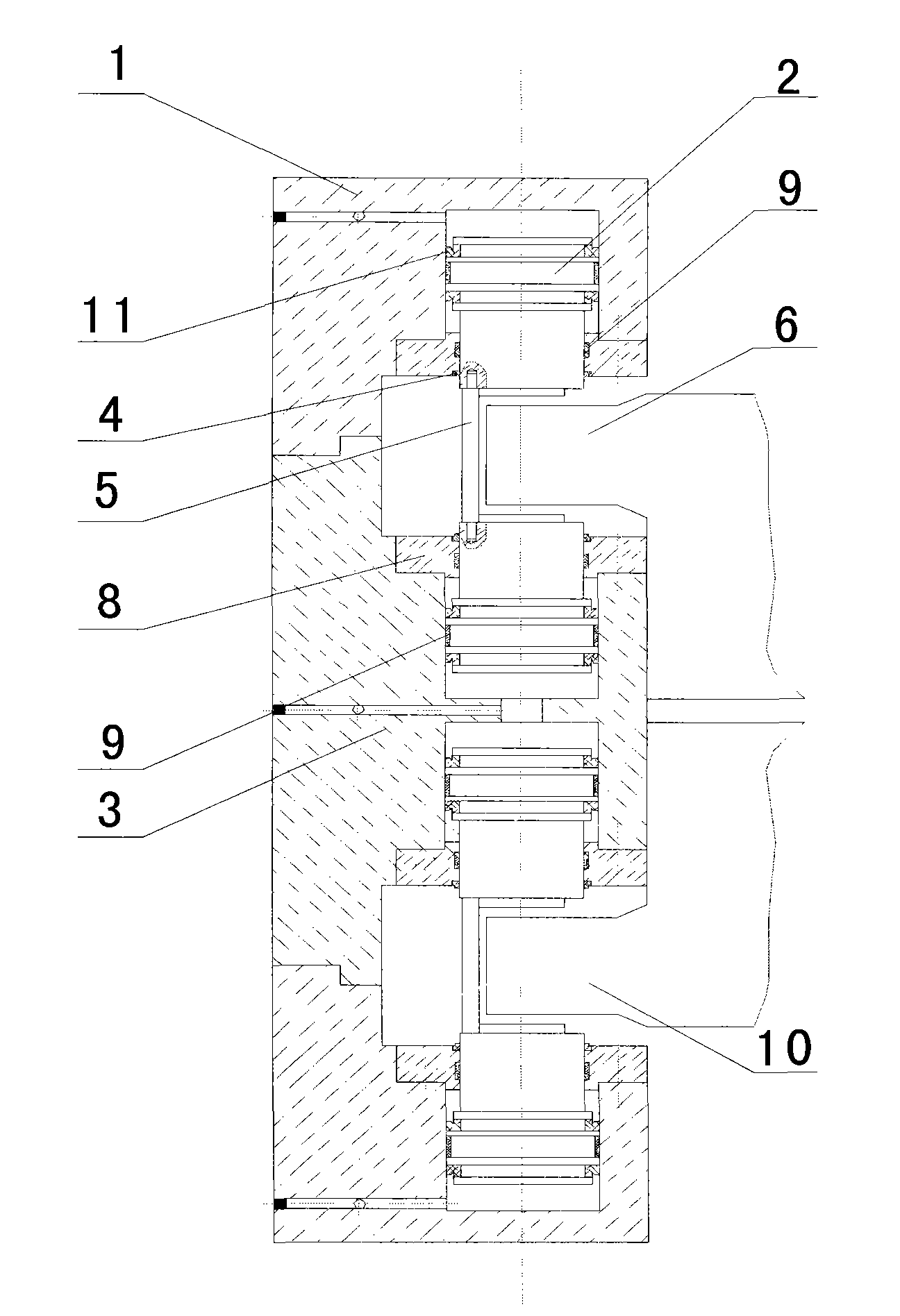

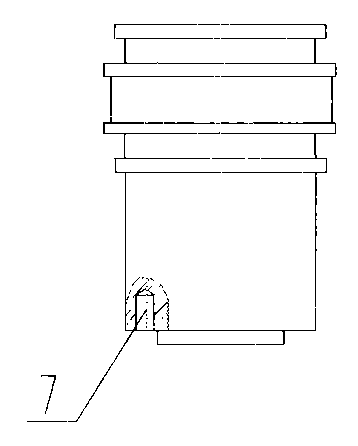

[0024] combine figure 1 , 2 , the design structure of the combined hydraulic cylinder that can provide positive and negative roll bending forces of the present invention consists of an end cylinder 1, a piston 2, an intermediate cylinder 3, a dustproof ring 4, a connecting rod 5, a flange cover 8, and a guide belt 9 , seal 11, wherein the end cylinder 1 is symmetrically installed on both ends of the middle cylinder 3, the end cylinder 1 and the middle cylinder 3 are provided with their own oil passages, the end cylinder 1 and the middle cylinder The same piston 2 is installed in the cylinder of the body 3, and the seal 11 is arranged on the piston 2, and one end surface of the piston 2 is designed with a counterbore 7, and each piston 2 installed in the cylinder is fixed by a flange cover 8 , the inner diameter of the flange cover 8 is designed with different annular grooves for installing the dust-proof ring 3 and the guide belt 9 respectively; two adjacent symmetrical and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com