Natural stone PU waterproof insulation board and preparation method thereof

A thermal insulation board and stone technology, applied in chemical instruments and methods, natural mineral layered products, roofs using flat/curved panels, etc., to achieve the effects of high airtightness, low air tightness, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

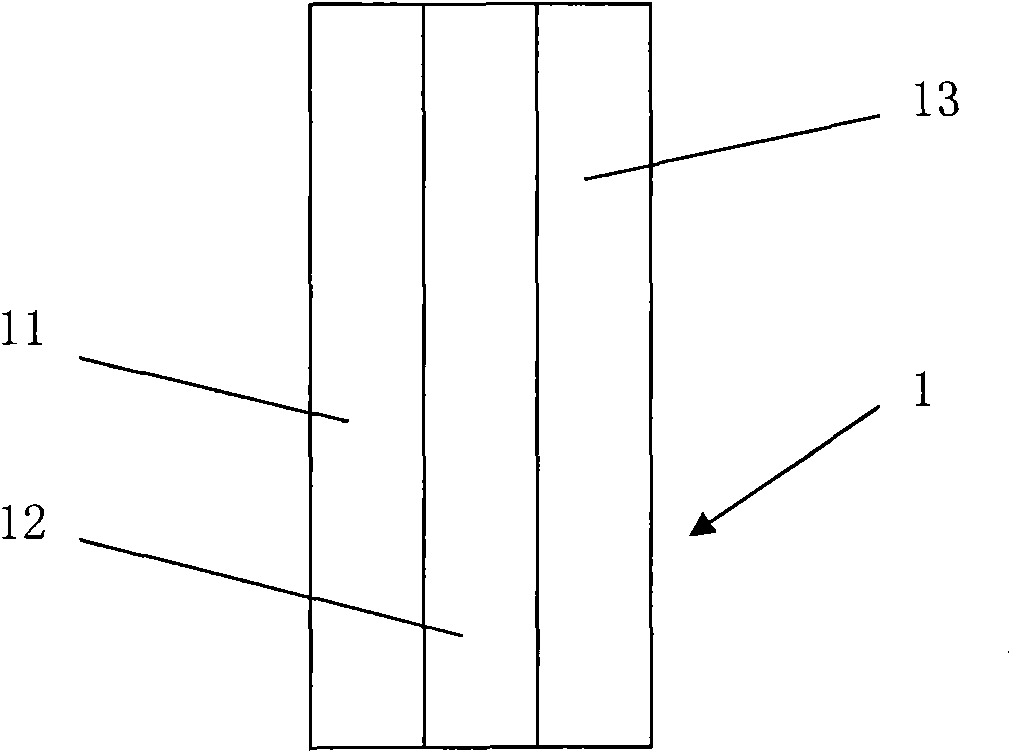

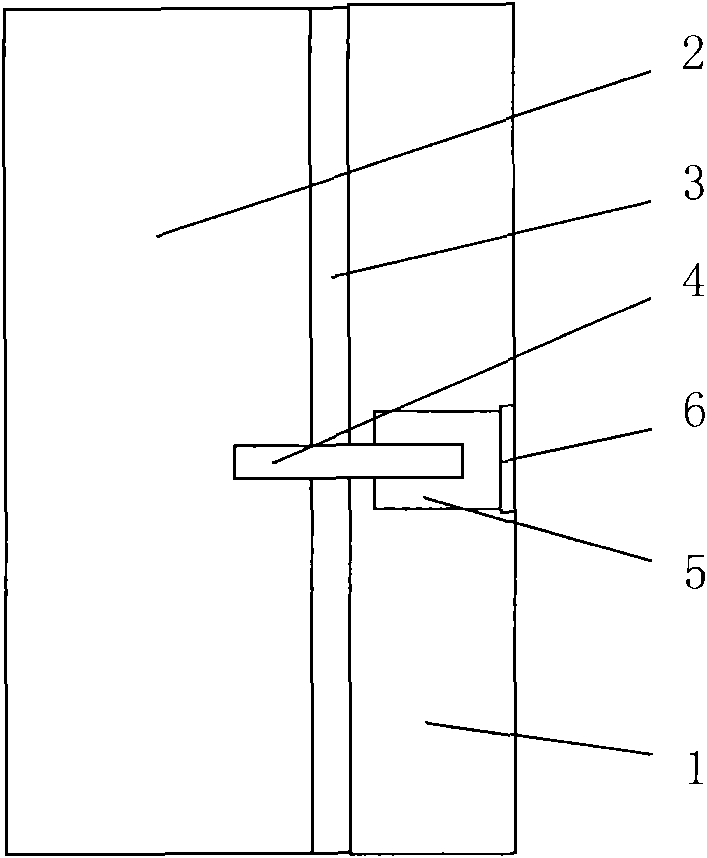

[0073] see figure 1 As shown in the layered structure diagram of the natural stone PU waterproof insulation board of the present invention, a method for preparing a natural stone PU waterproof insulation board using polyurethane foam spraying technology, using natural stone 11 as the base layer, passing the component stock solution of rigid polyurethane through The sprayer mixes and rotates at high speed and impacts violently, forming fine mist droplets at the nozzle of the spray gun and spraying them evenly on the surface of natural stone. The polyurethane foams and solidifies to form a hard polyurethane foam layer 12. After curing, the hard polyurethane foam The surface of layer 12 is coated with waterproof interface layer 13 .

[0074] Described rigid polyurethane comprises following component by weight:

[0075] Polyether polyol based on o-toluenediamine 100 parts

[0076] Polymethylene polyphenylisocyanate 108 parts

[0077] Blowing agent 1,1-dichloro-1-fluoroethane 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com