Vibration waveform controlling system of electro-hydraulic exciter

A technology of vibration waveform and electro-hydraulic excitation, which is applied in the direction of electrical program control, vibration test, and feedback control, can solve the problems of large output waveform distortion, small output waveform distortion, and low precision, and achieve control accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

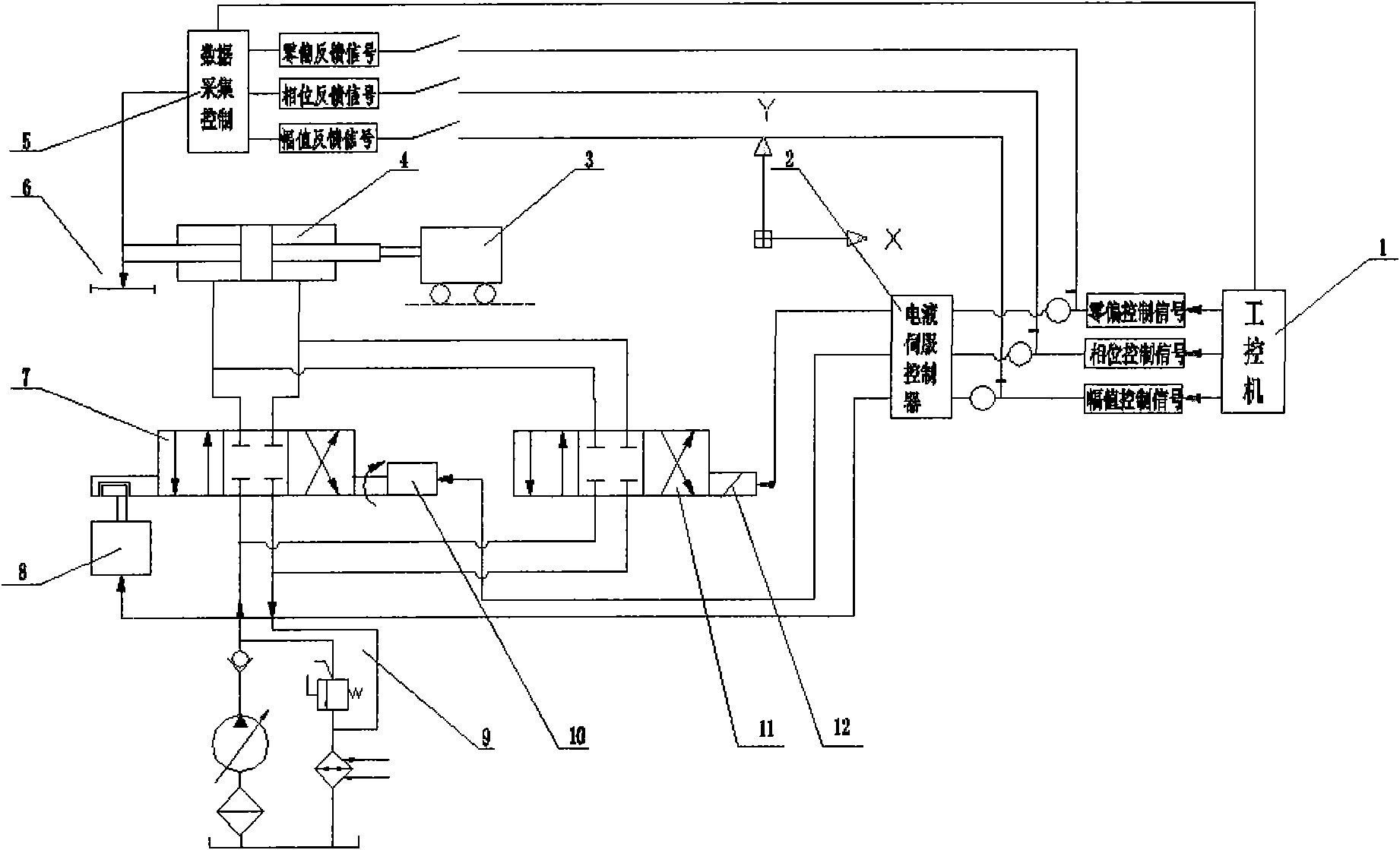

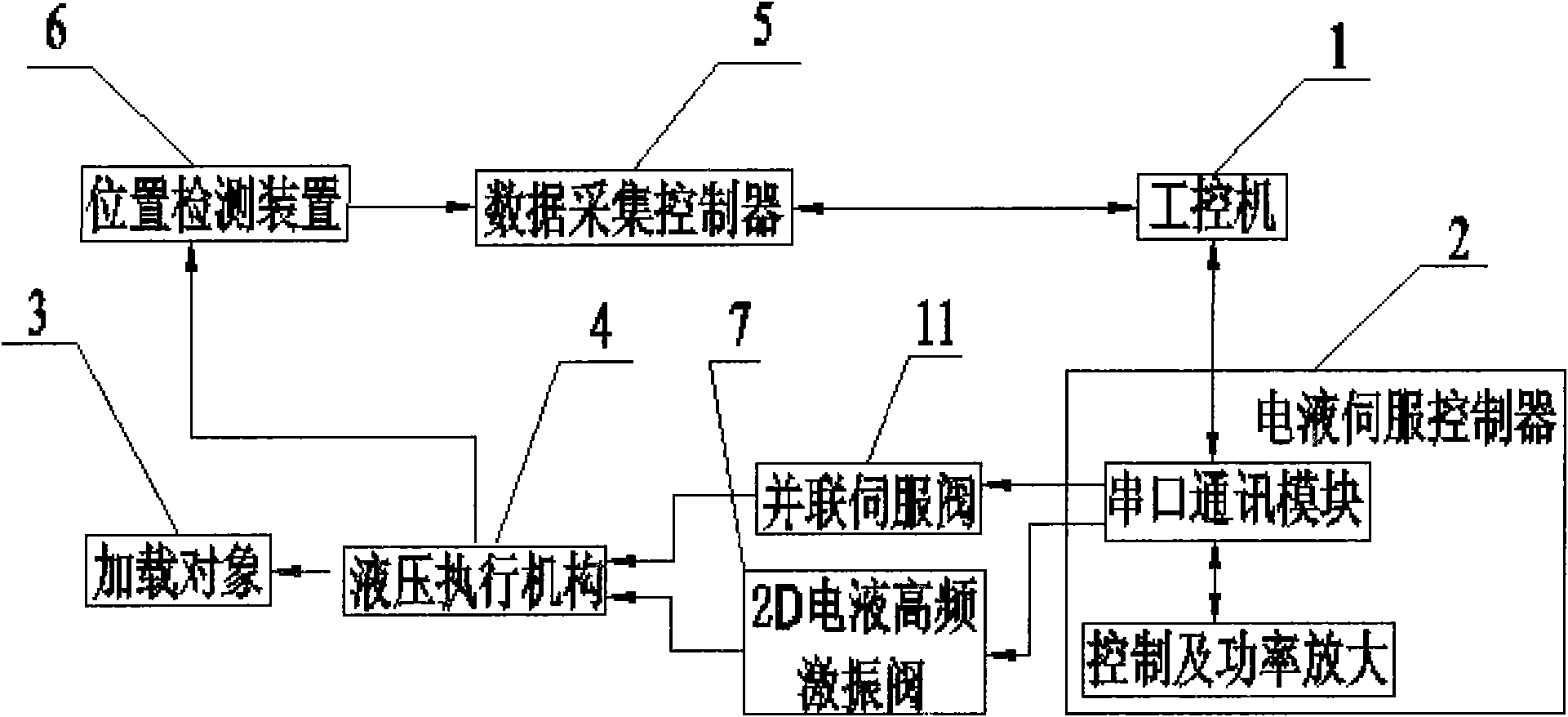

[0023] refer to figure 1 , image 3 , Figure 4 , an electro-hydraulic vibrator vibration waveform control system, including an oil source 9, a high-frequency excitation valve, a parallel servo valve 11, a hydraulic actuator 4 and a loading object 3; the oil source 9 and the high-frequency excitation valve, The parallel servo valve 11 is connected, the high-frequency excitation valve and the parallel servo valve 11 are connected to the hydraulic actuator 4, the hydraulic actuator 4 is connected to the loading object 3, and the parallel servo valve 11 includes The zero-bias servo motor 12 that controls the cam mechanism to push the spool of the parallel servo valve to slide, the high-frequency excitation valve is a 2D electro-hydraulic high-frequency excitation valve 7, and the 2D electro-hydraulic high-frequency excitation valve 7 includes An axial servo motor 10 for controlling the axial sliding of the spool of the excitation valve; the closed-loop control system also inclu...

Embodiment 2

[0036] refer to figure 1 , image 3 with Figure 4 , the 2D electro-hydraulic high-frequency excitation valve 7 of this embodiment also includes a rotary servo motor 8 for controlling the rotation of the vibration valve spool, and the rotary servo motor 8 is connected to the electro-hydraulic servo controller 2; In the control execution module, the set excitation waveform signal is also decomposed into a phase control signal; in the feedback comparison module, the phase feedback signal after decomposing the displacement waveform signal detected by the position detection device is compared with the phase control signal, And send the compared difference signal to the electro-hydraulic servo controller.

[0037] The control parameters of this embodiment also include phase, which is used to control the zero offset (average value of the output waveform), phase and amplitude of the electro-hydraulic vibrator output wave excitation waveform. The electro-hydraulic servo decompositio...

Embodiment 3

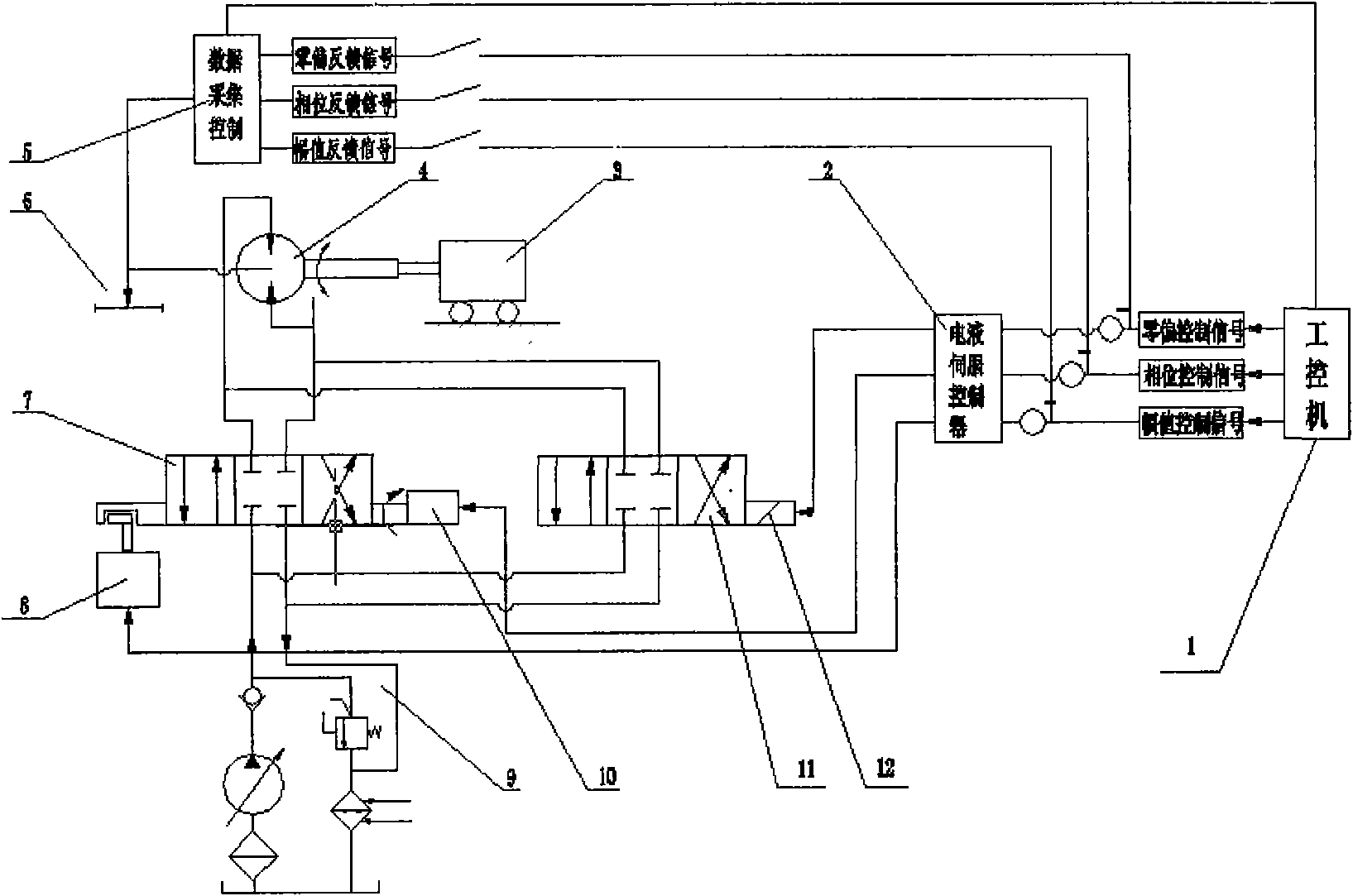

[0045] refer to figure 2 , image 3 , Figure 4 , in this embodiment, the parallel servo valve spiral servo three-position four-way slide valve structure includes a servo motor 12, and the servo motor 12 pushes the spool to slide through the spiral servo structure to control the movement of the valve core into and out of the electro-hydraulic vibration cylinder 4. The direction and size of the oil.

[0046] When the electro-hydraulic excitation cylinder 4 is a hydraulic motor, the 2D electro-hydraulic high-frequency excitation valve 7 and the parallel servo valve 11 control the piston of the hydraulic motor to rotate back and forth to make the loaded object torsionally vibrate.

[0047] The displacement detection device is an angle sensor 6, which detects the back and forth rotational angular displacement of the piston when the hydraulic motor vibrates.

[0048] Other structures and working processes of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com