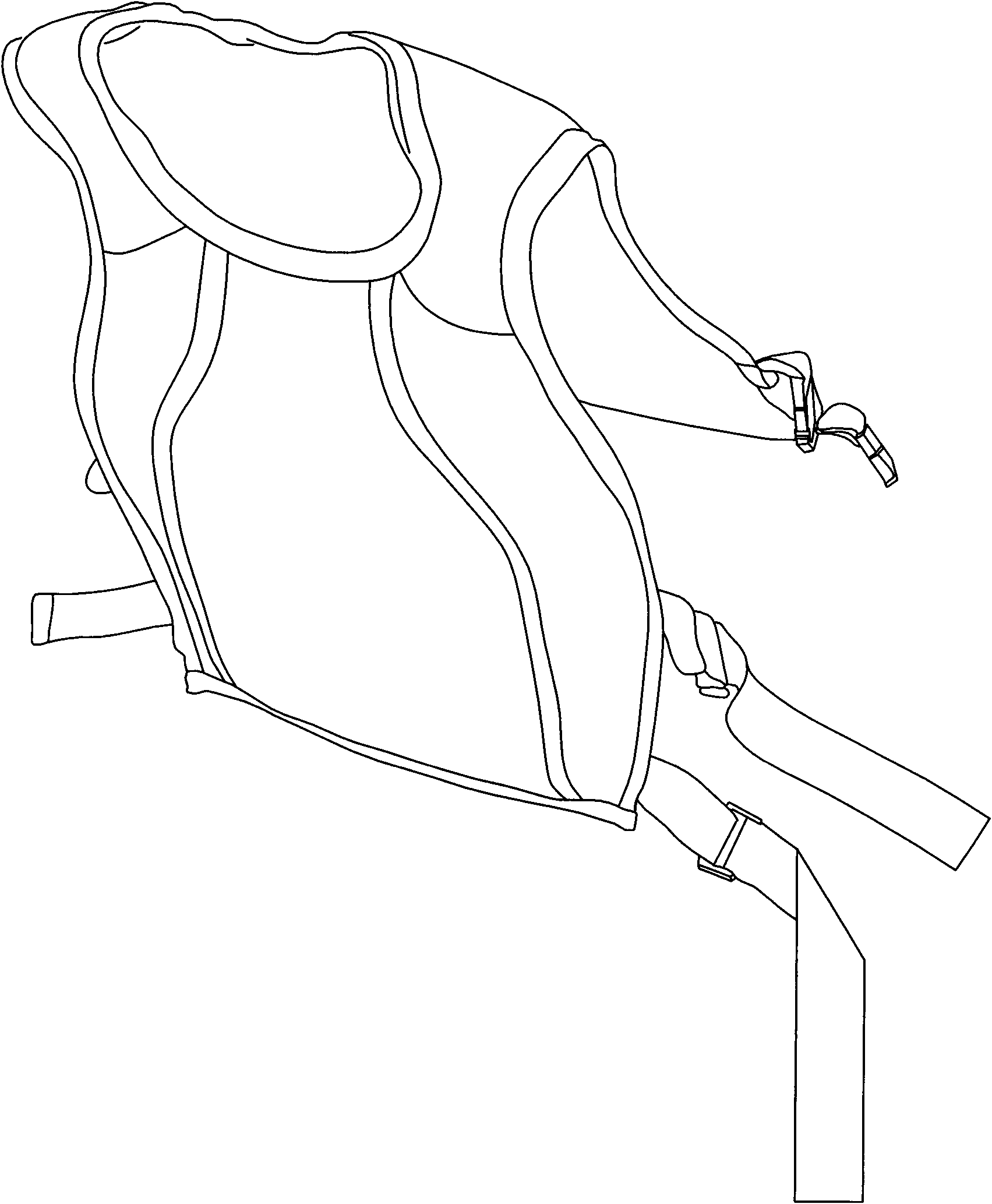

Safety vest

A vest and safety technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of not being able to be used as a life jacket, inconvenient for wearing personnel, and small in scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

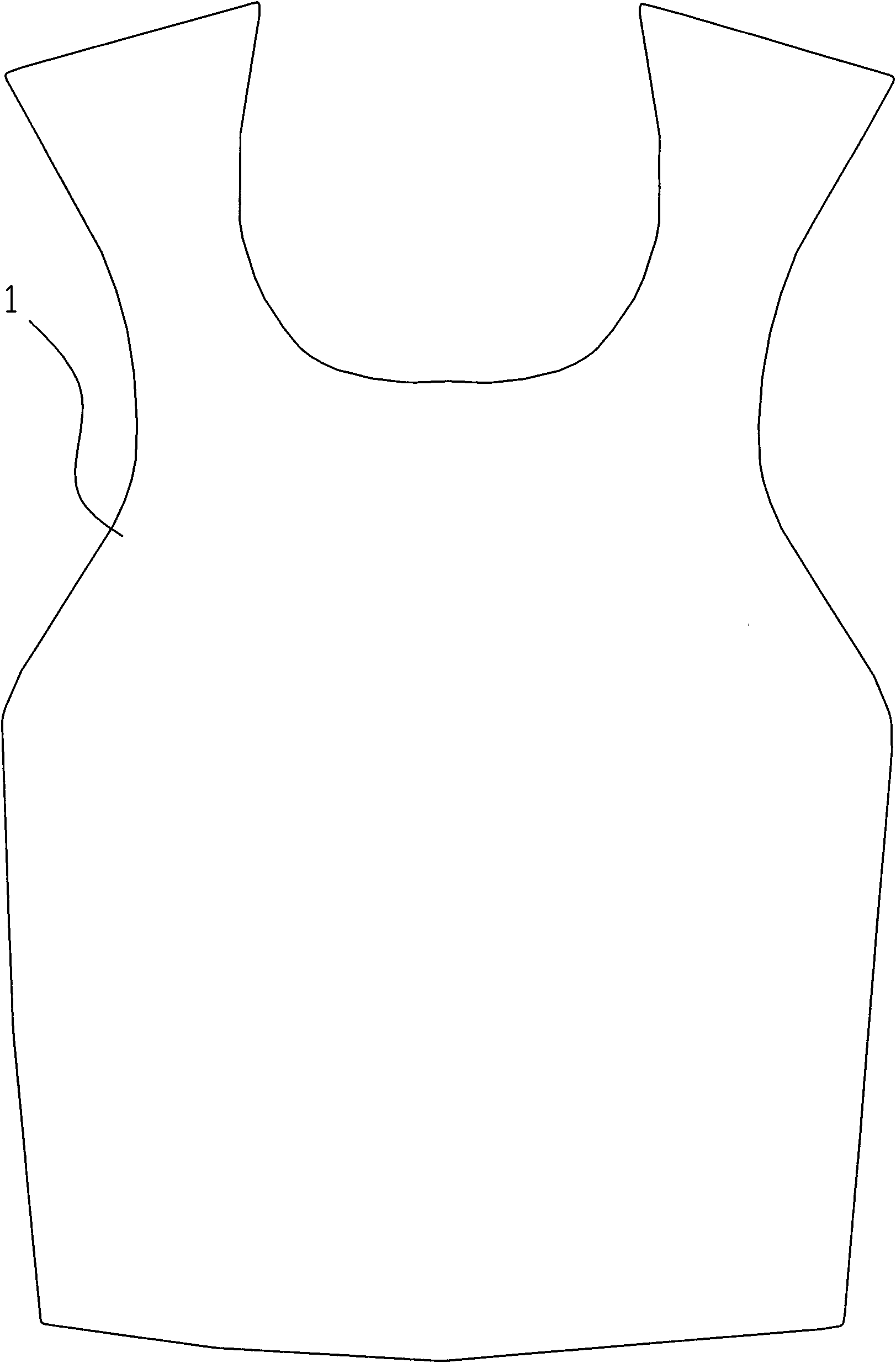

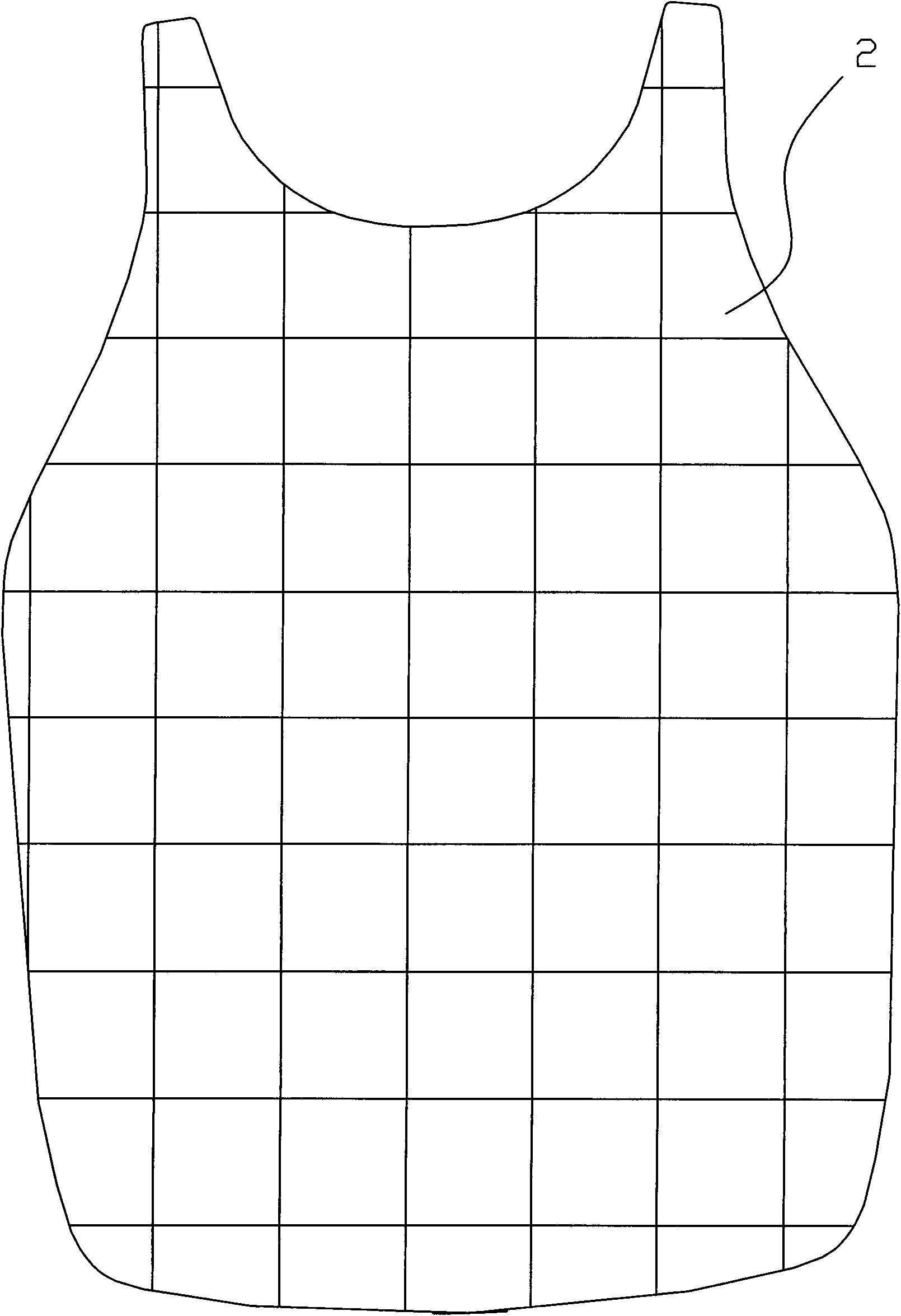

[0018] Embodiment 1, the safety vest of this embodiment includes a vest jacket 1 and an inner core 2, and the surface of the inner core 2 is designed as a concave-convex mahjong block suitable for human activity rules. The outer fabric of the outer jacket is made of elastic silk fabric, the surface fabric is two layers, and a layer of SBR material with a thickness of 1mm is sandwiched between the two layers, while the inner fabric is one layer, and the surface is covered with a layer of SBR with a thickness of 1mm. material layer. The inner core 2 is sandwiched in the interlayer of the outer jacket 1. The inner core 2 of the inner core 2 placed in the front outer jacket 1 is at least one third thicker than the inner core 2 placed in the back outer jacket, and its density is 0.07 g / cm 3 The basic composition of the foam material inner core 2 is: 82% of vinyl acetate copolymer, 13% of calcium carbonate filler, 2.3% of azodicarbonamide foaming agent, The foaming aid is 1%, the ...

Embodiment 2

[0022] Embodiment 2, the safety vest of this embodiment includes a vest jacket 1 and an inner core 2, and the surface of the inner core 2 is designed as a concave-convex mahjong block suitable for human activity rules. The outer fabric of the outer jacket is made of elastic silk fabric, the surface fabric is two layers, and a layer of SBR material with a thickness of 1mm is sandwiched between the two layers, while the inner fabric is one layer, and the surface is covered with a layer of SBR with a thickness of 1mm. material layer. The inner core 2 is sandwiched in the interlayer of the outer jacket 1. The inner core 2 of the inner core 2 placed in the front outer jacket 1 is at least one third thicker than the inner core 2 placed in the back outer jacket, and its density is 0.07 g / cm 3 The basic composition of the foam material inner core 2 is: 82.5% of vinyl acetate copolymer, 12% of calcium carbonate filler, 3.3% of azodicarbonamide foaming agent, Foaming aid zinc oxide is...

Embodiment 3

[0026] Embodiment 3, the safety vest of this embodiment includes a vest jacket 1 and an inner core 2, and the jacket 2 is made of elastic silk fabric, and the face cloth is two layers, and sandwiched between the two layers has a thickness of The SBR material layer is 1mm, and the lining is a layer, and the surface is covered with a layer of SBR material with a thickness of 1mm. The inner core 2 is sandwiched in the interlayer of the outer jacket 1, and the inner core 2 placed in the front outer jacket 1 is at least one third thicker than the inner core 2 placed in the back outer jacket, and its density is 0.07g / cm 3 The basic composition of the foam material inner core 2 is: 83% of vinyl acetate copolymer, 11% of calcium carbonate filler, 4.3% of azodicarbonamide foaming agent, The foaming aid is 0.6%, the crosslinking agent is 0.5%, and the stearic acid lubricant is 0.6%. The above percentages are mass percentages. The EVA refers to vinyl acetate copolymer. The safety vest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com