Anti-coking process of oiling device and automatic decoking device

An anti-coking and process technology, applied in the field of anti-coking process, can solve the problems of affecting materials, multiple raw materials and energy, increase of material flow pressure difference, etc., so as to solve the coking problem, ensure the service life, and reduce the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

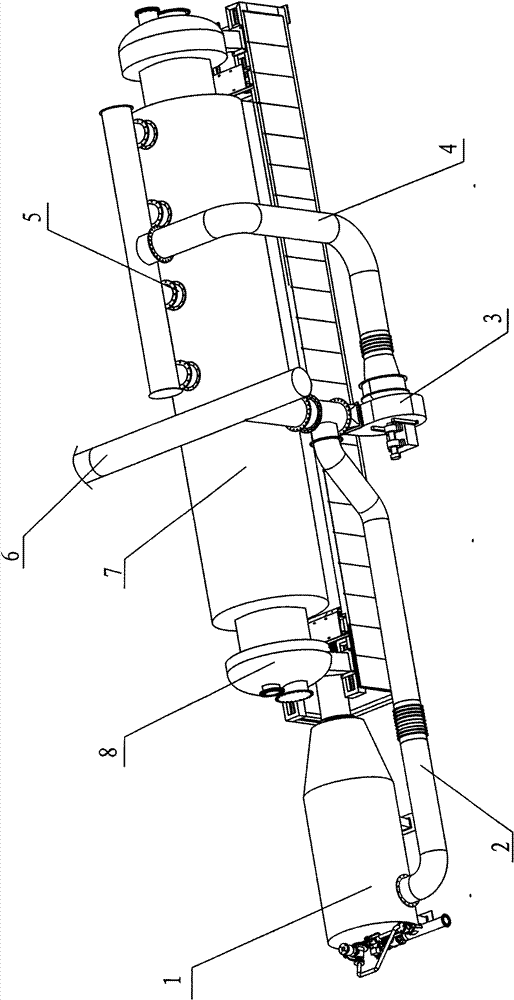

[0027] An anti-coking process. The hot air discharged from the cracker is directly delivered to the hot air inlet of the cracker through a pipeline, mixed with the high temperature hot air that will be sent to the cracker before entering the cracker, and then enters the hot air cavity of the cracker. After measurement, the temperature of the hot air discharged from the cracker is 410-420°C, and the temperature at the heater outlet (before mixing) is 1200°C. After mixing, the temperature of the hot air acting on the inner wall of the cracker is 500-550°C. The outlet temperature is 380-400°C. The coking phenomenon on the inner wall of the cracker has been improved.

Embodiment 2

[0029] An anti-coking process. The hot air discharged from the cracker is directly sent to the regenerative fan through the pipeline, and the air volume is increased by the regenerative fan and then sent to the hot air inlet of the cracker. The high-temperature hot air that will be sent to the cracker before entering the cracker After mixing, enter the cracker hot air cavity. After measurement, the temperature of the hot air discharged from the cracker is 415-420°C, and the temperature of the hot air at the heater outlet is 1300°C. After the air volume is increased by the regenerative fan, and after mixing, the temperature of the hot air acting on the inner wall of the cracker is 520- 540℃, the temperature of the oil and gas outlet of the cracker is 380-400℃. The coking phenomenon on the inner wall of the cracker has been improved.

Embodiment 3

[0031] An anti-coking process. The temperature of each hot air outlet of the cracker is measured by a temperature control device, and the air volume of each air outlet is adjusted through a wind control valve. The hot air discharged from each air outlet is mixed through the pipeline and directly sent to the heat recovery fan. The hot air blower increases the air volume and sends it to the hot air inlet of the cracker. It is mixed with the high temperature hot air that will be sent to the cracker before entering the cracker in the mixing chamber, and then enters the cracker hot air chamber. After measurement, the temperature of the hot air discharged from the cracker is 400-410°C, and the temperature of the hot air at the heater outlet is 1270°C. After the air volume is increased by the regenerative fan, the ratio of the hot air discharged from the cracker to the high-temperature hot air that will be sent to the cracker After mixing with a ratio of 2-2.5:1, the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com