Drying technique of viscous strain material and equipment thereof

A drying process and material technology, applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve the problem that the drying effect is not very ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

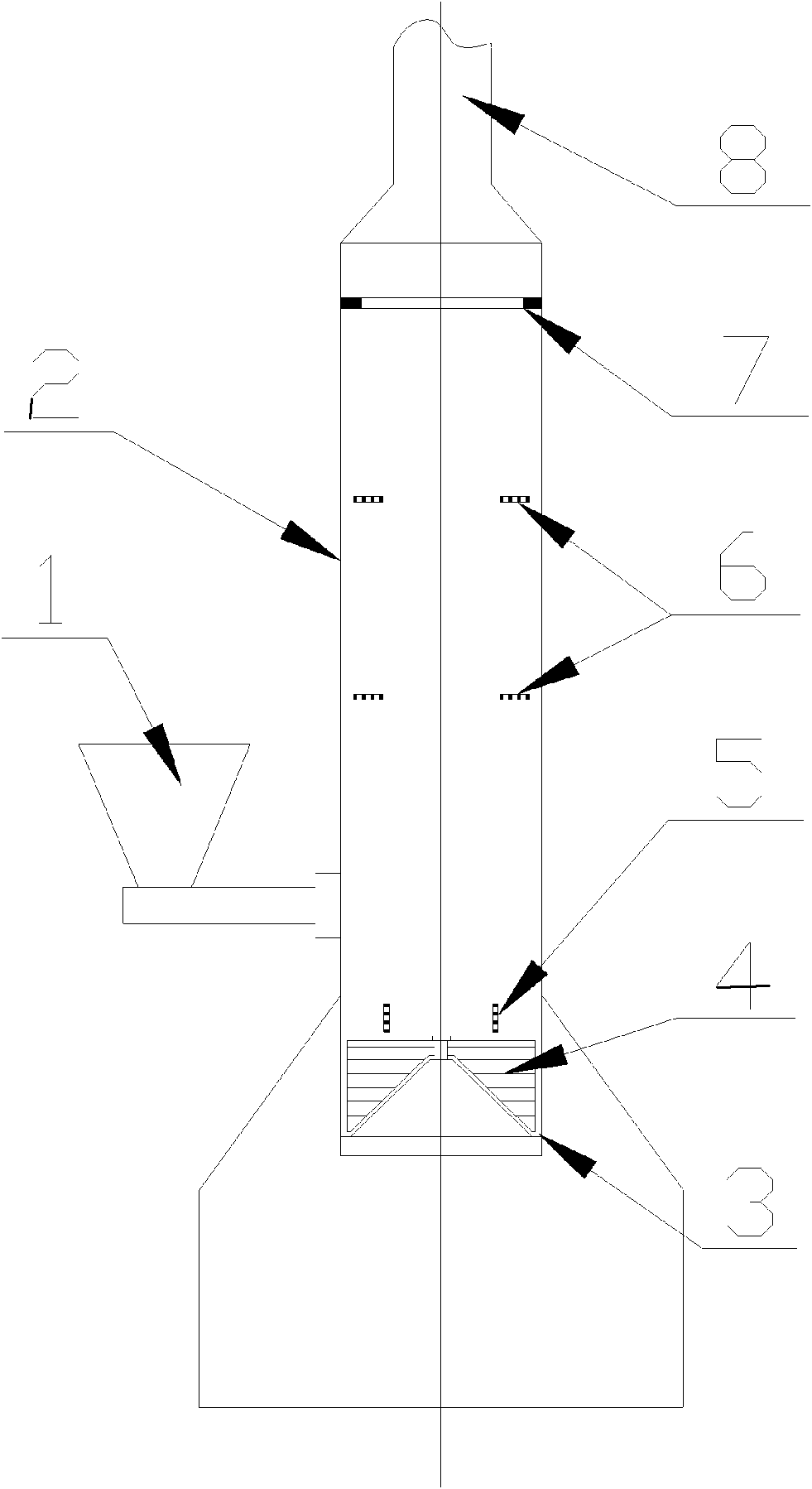

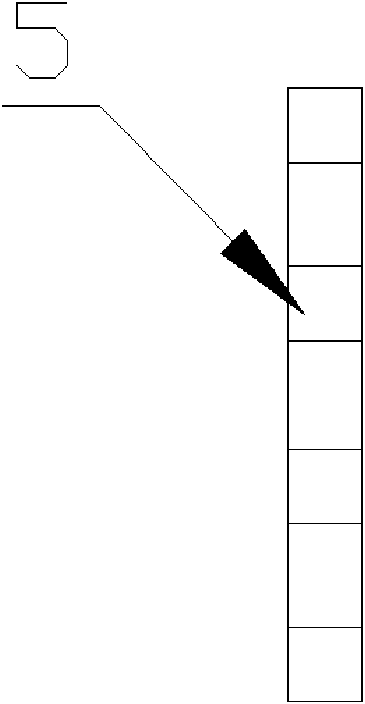

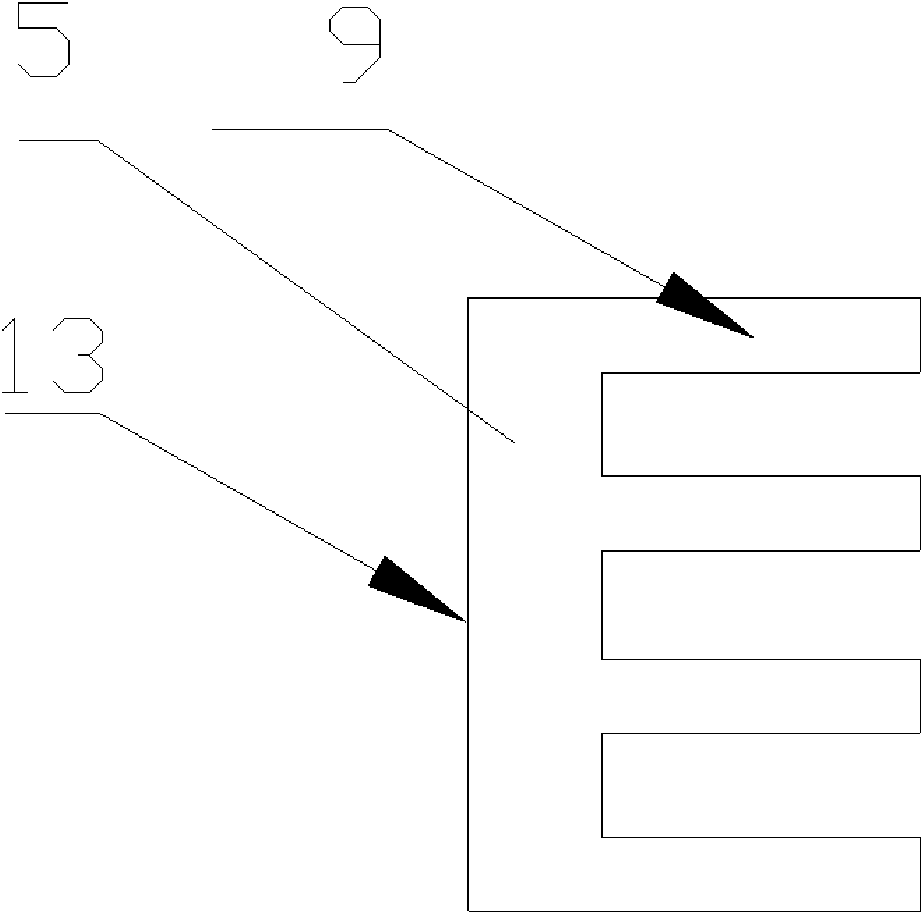

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , on the inner wall of the main pipe tower 2, near the upper position of the 4 blades of the crusher, four impact grids 5 are added. The grid teeth 9 are composed of 2 or more teeth, and four turbulence grids 6 are fixed horizontally and symmetrically between the grading ring 7 and the impact grid 5 on the inner wall of the main pipe tower 2, and the turbulence grids 6 are fixed and installed horizontally. At a distance of 80-120 cm from the crusher 4, the grid teeth 10 of the turbulence grid 6 consist of two or more teeth.

[0025] The present invention uses the upward centrifugal force of the blades of the crusher 4 to throw the viscous material to the wall of the main pipe tower 2, collides with the impact grid 5 on the wall of the main pipe tower 2 to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com