Swing mirror angle scanning characteristic test device for camera

A test device and angle scanning technology, which is applied in the field of camera swing mirror swing angle scan characteristic test device, can solve the problems that non-contact measurement cannot be realized, non-contact measurement is not solved, and the use range is limited, so as to simplify the measurement steps, The effect of eliminating angle drift and improving the efficiency of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

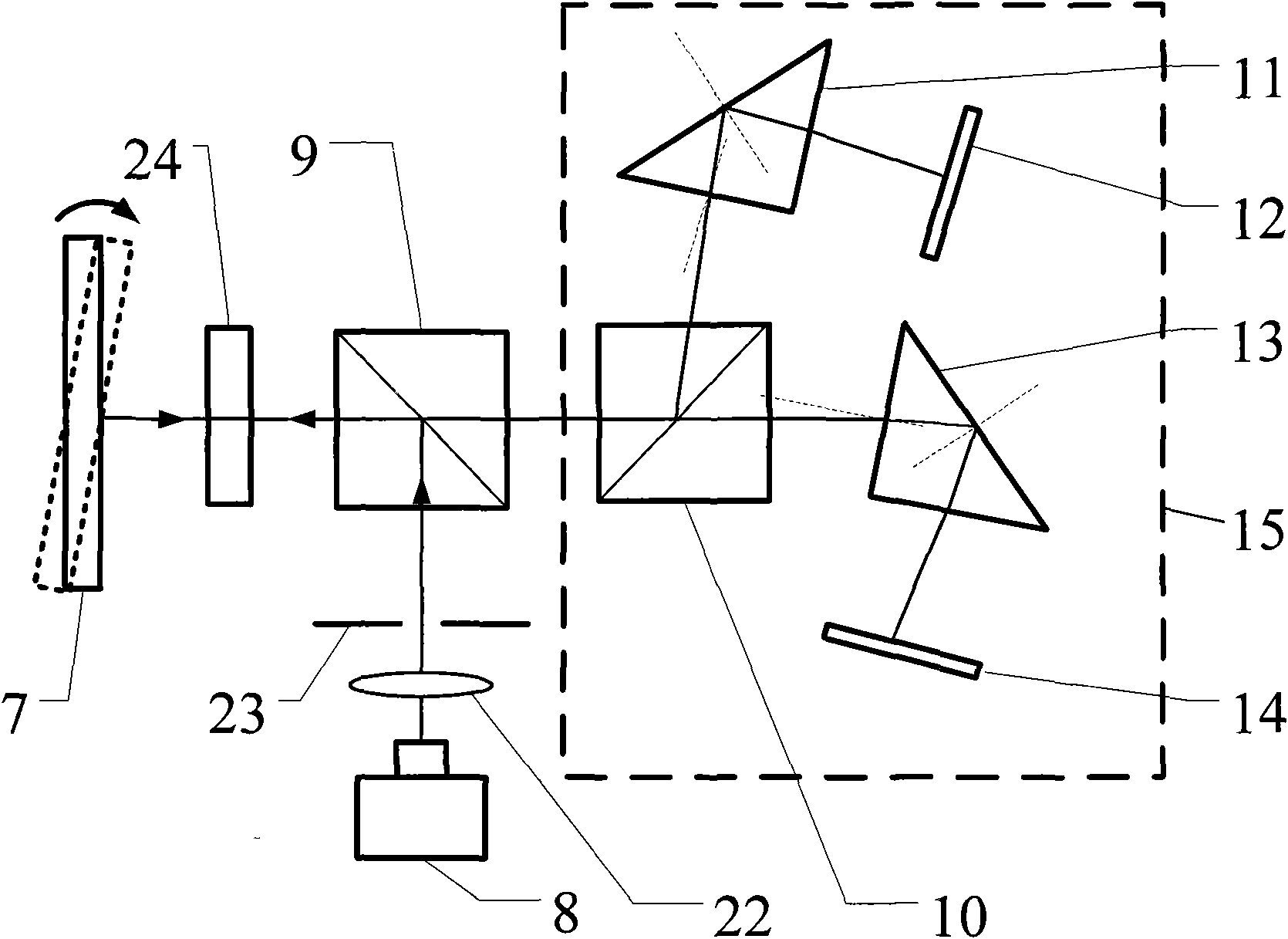

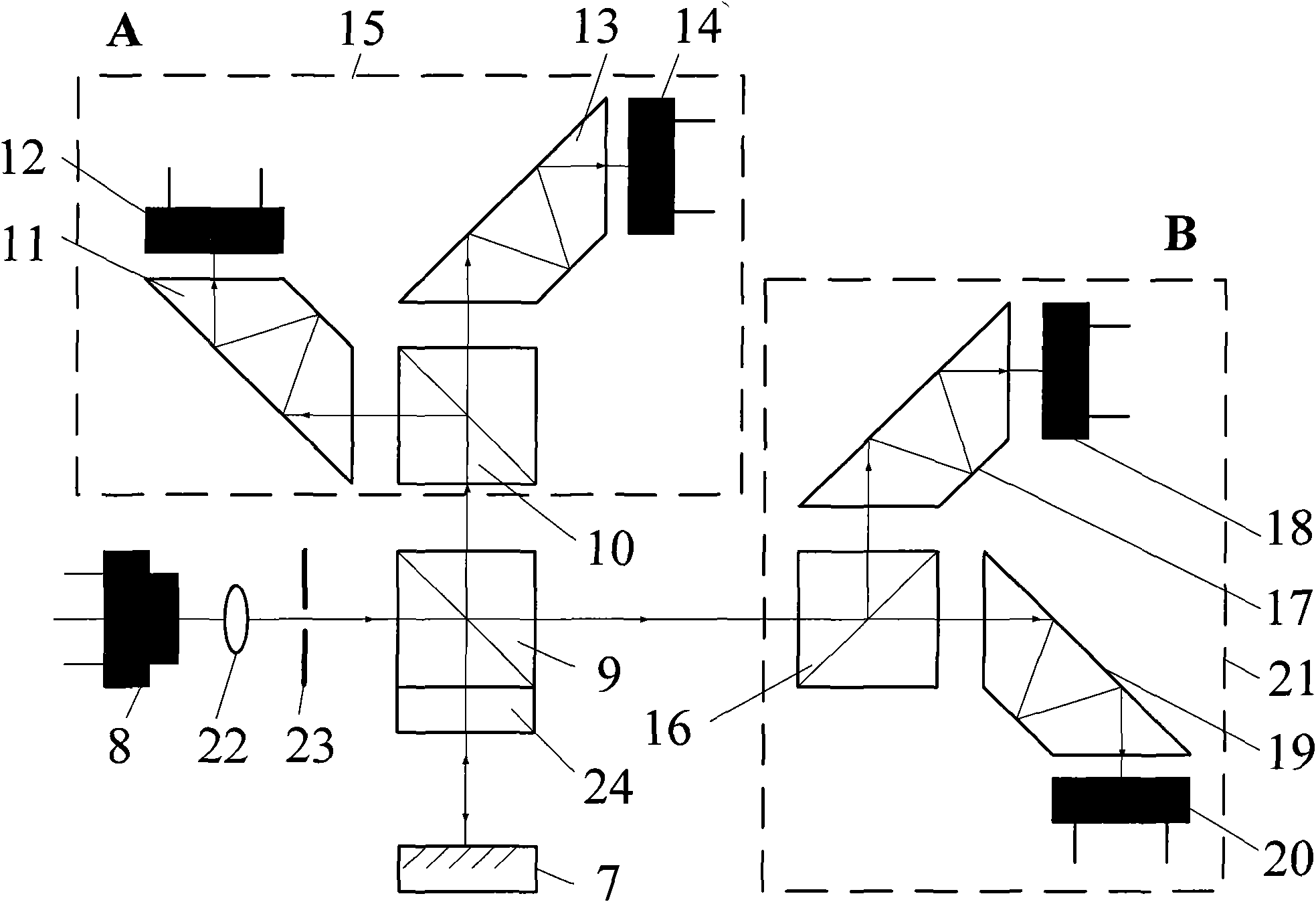

[0027] The technical principle of the present invention is: using differential internal reflection goniometric technology to place the reflectors of the small-angle non-contact tracking dynamic goniometric optical path in the reflection and transmission directions of the beam splitter respectively to form a differential critical reflection structure. The light intensity signals from different angles detected by the detector can realize high-precision tracking measurement of the measured angle through calculation; in addition, the introduction of a high-precision circular grating angle measurement system, combined with the data fusion processing system, expands the system range and realizes dynamic Measurement.

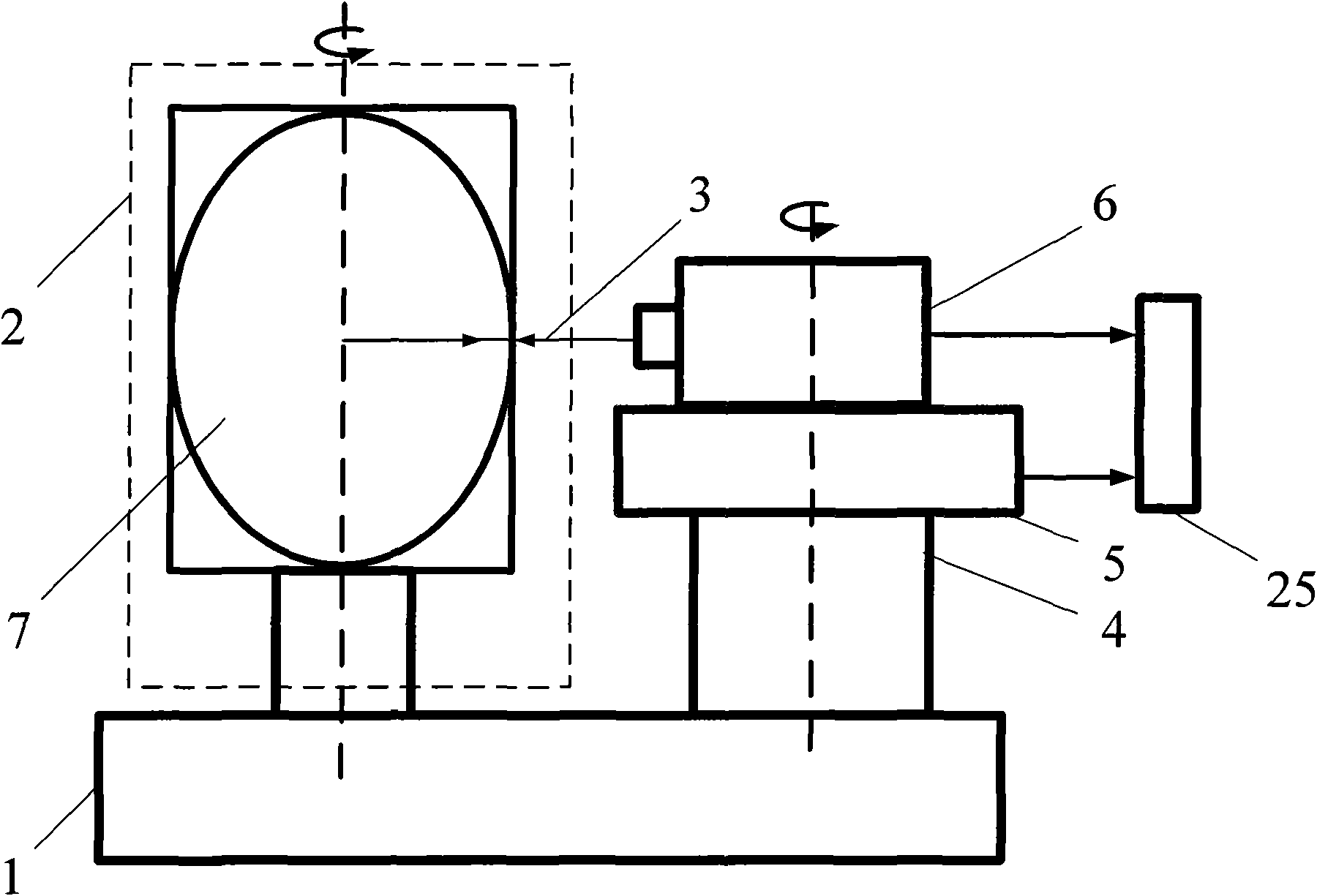

[0028] The structure of the test device for the scanning characteristics of the swing mirror swing angle of the camera of the present invention is as follows: ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap