Electric heater

A technology of electric heater and power supply, which is applied in the direction of ohmic resistance heating, electric heating device, heating element material, etc. It can solve the problems of unusable, processing and cooking food, etc., and achieve the effect of increasing the occasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

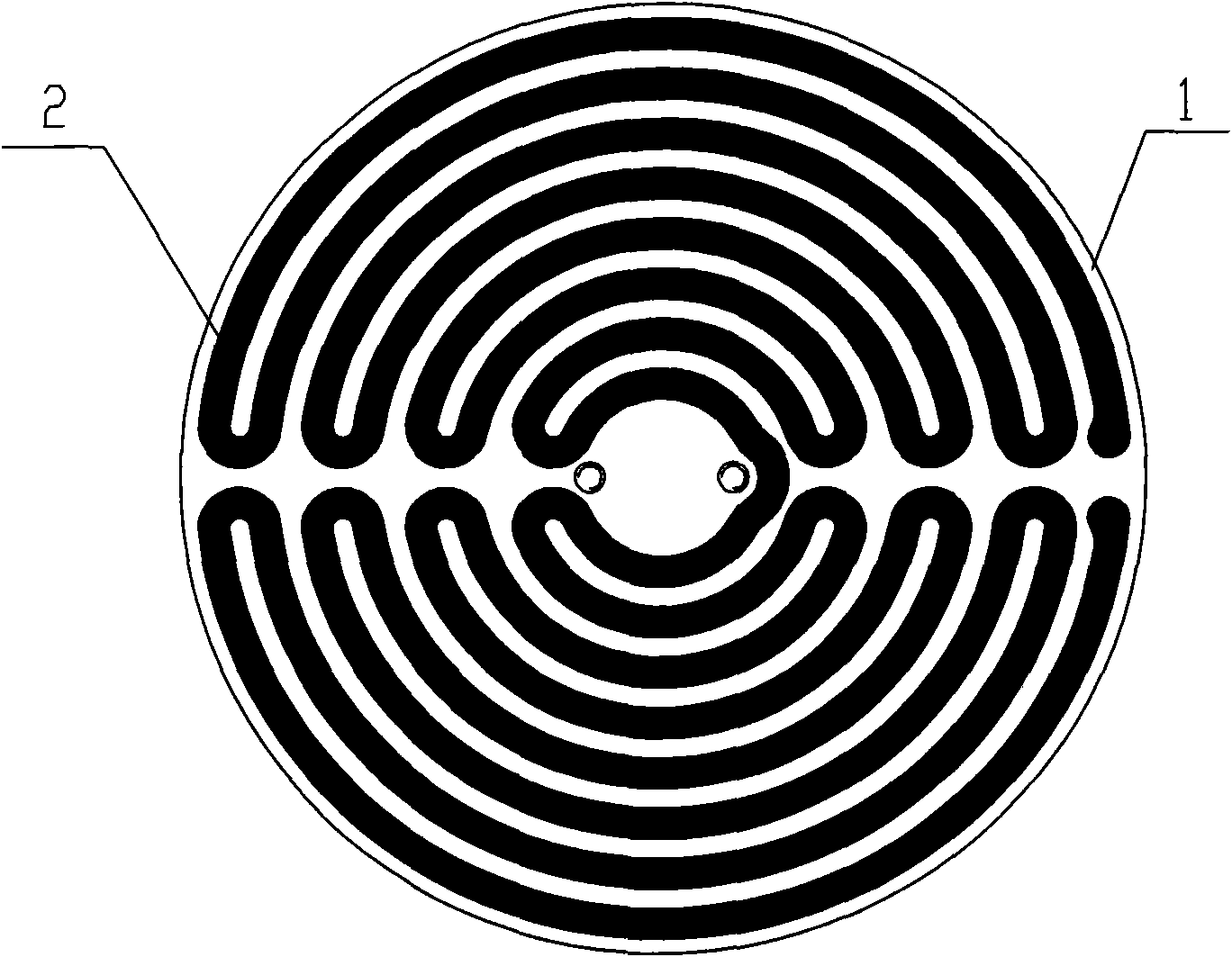

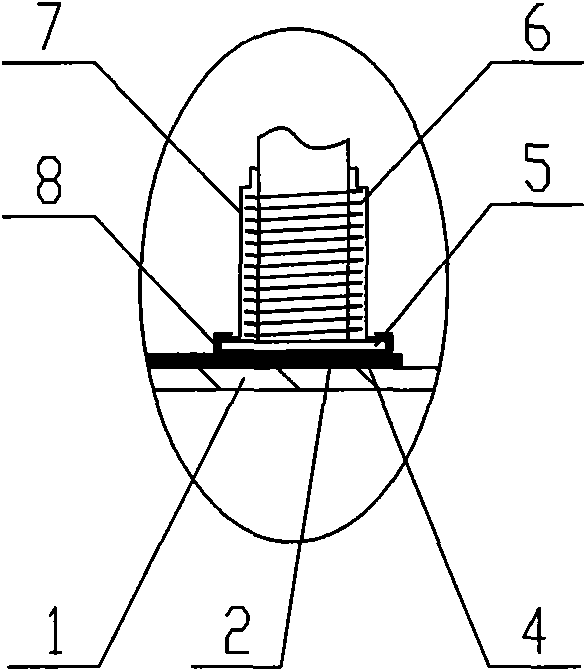

[0031] Figure 1~3 The electric heater shown is the first embodiment of the present invention, which includes a substrate 1, a heating element 2 made of a rare earth thick film material (also can be understood as at least 2 or more heating elements, and each heating element is Through the control circuit, the control circuit connects the heating elements in series, which is equivalent to a long heating element), wherein the substrate 1 is a stainless steel substrate or copper plate, and the heating element 2 is fixed on the substrate 1 by sintering after printing; the heating element 2 are all connected with the car storage battery or the engine power supply through the control circuit.

[0032] The two ends of the heating element 2 are connected to the control circuit through the connecting piece. The structural composition of the connecting piece includes: a hole with the mouth facing down at the bottom of the barrel is directly fixed (or fixed by a pressing sheet) on the su...

Embodiment 2

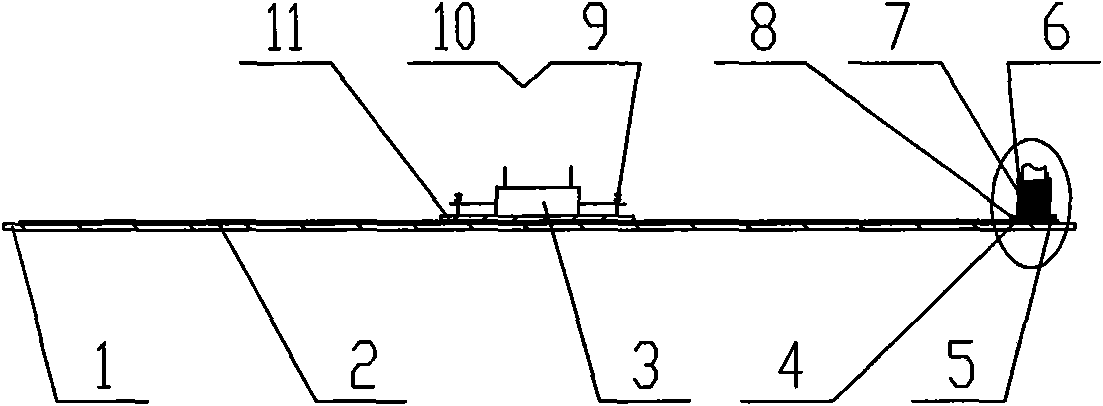

[0036] Figure 4~5 The electric heater shown is the second embodiment of the present invention. It differs from the first embodiment in that: this embodiment is provided with four heating elements 2, and the two ends of each heating element are provided with power connectors, and the The control circuit connects the heating elements in series or in parallel to the power supply.

[0037] When the control circuit is used to cycle through each heating element and the power supply, a heating element starts to work with a fixed power according to the preset working rhythm, and other heating elements do not work; when a certain heating element is powered on, it will work for a certain After a certain period of time, the control circuit automatically switches to another heating element to turn on the power supply and continue to work, and the cycle is repeated in turn. The power of each heating element should not exceed the load power of the wire each time. Food is processed until c...

Embodiment 3

[0039] The heating element and the base plate are arranged on the inner surface of the die-cast copper alloy or aluminum alloy part 13, and then covered with a heat insulating cover 12.

[0040] The principle and structural design of the present invention are reasonable, and through reciprocating and cyclic heating, the substrate continuously accumulates heat and transfers it to the food to be processed, so that the food is gradually heated and cooked.

[0041]The application of the present invention can improve people's daily work and living conditions, especially for long-distance driving, winter cold journeys, pommel horse fatigue, experience cooking coffee, brewing tea, toasted sandwiches, bread slices, fried eggs, etc. While satisfying and filling the belly, I also experienced the fun of doing it myself.

[0042] The low-voltage DC series electrical appliances integrating driving, life and fun have huge development potential and broad market and economic prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com