Detoxifying pre-treated lignocellulose-containing materials

A lignocellulose and pretreatment technology, applied in the post-processing of cellulose pulp, fiber raw material processing, biofuels, etc., can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0332] Pretreatment of completely unwashed pretreated corn stover (fuwPCS)

[0333] Corn stover (PCS) erupted with dilute acid vapor was diluted with water and treated with NH 4 OH to pH 5.0. The total solids (TS) level was 15% by weight. This sample was then saccharified with Cellulolytic Preparation A at 50°C for 63 hours. Penicillin was added at a rate of 1 g / L and citrate buffer was also added at a rate of 50 mL of 1M citrate buffer per 100 ml of substrate prior to saccharification. Following the saccharification step, samples were filtered through a 0.2 micron Nalgene vacuum filter system (Product #8-0000-43-0803) to remove solids and used for fermentation. Then use a pipette to transfer the fuwPCS into a separate sterile container containing CO 2 15mL conical centrifuge tube with small vent.

[0334] Formulated (Gallic Acid)

[0335] with H 2 SO 4 The pH was adjusted to about 2; gallic acid was formulated at concentrations of 2 mM (GaA-L) and 10 mM (GaA-H). Ga...

Embodiment 2

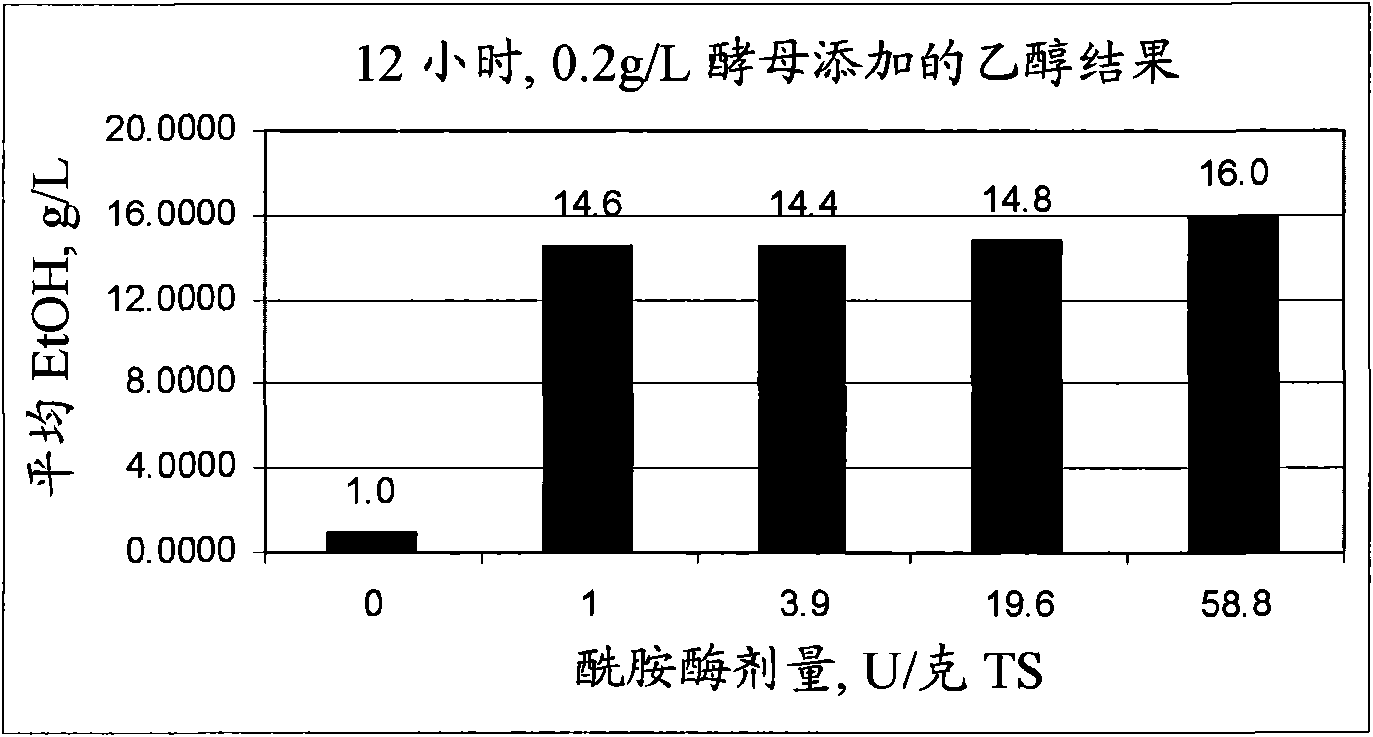

[0345] Carbonic anhydrase and amidase

[0346] Pretreated corn stover saccharification

[0347] Corn stover (PCS) erupted with dilute acid vapor was diluted with water and treated with NH 4 OH to pH 5.0. The total solids (TS) level was 16%. This sample was then saccharified with Cellulolytic Preparation A at 50°C for 72 hours. Penicillin and citrate buffer were also added prior to saccharification. After the saccharification step, the samples were filtered to remove solids, and the filtrate was used for fermentation. Then use a pipette to transfer the fuwPCS into a separate sterile container containing CO 2 15mL conical centrifuge tube with small vent.

[0348] yeast preparation

[0349] Freeze-dried RED STAR TM Ethanol Red yeast was rehydrated in 10x YP medium for 30 minutes at 32°C. It was formulated into the fermentation at a dose of 0.2 g / L.

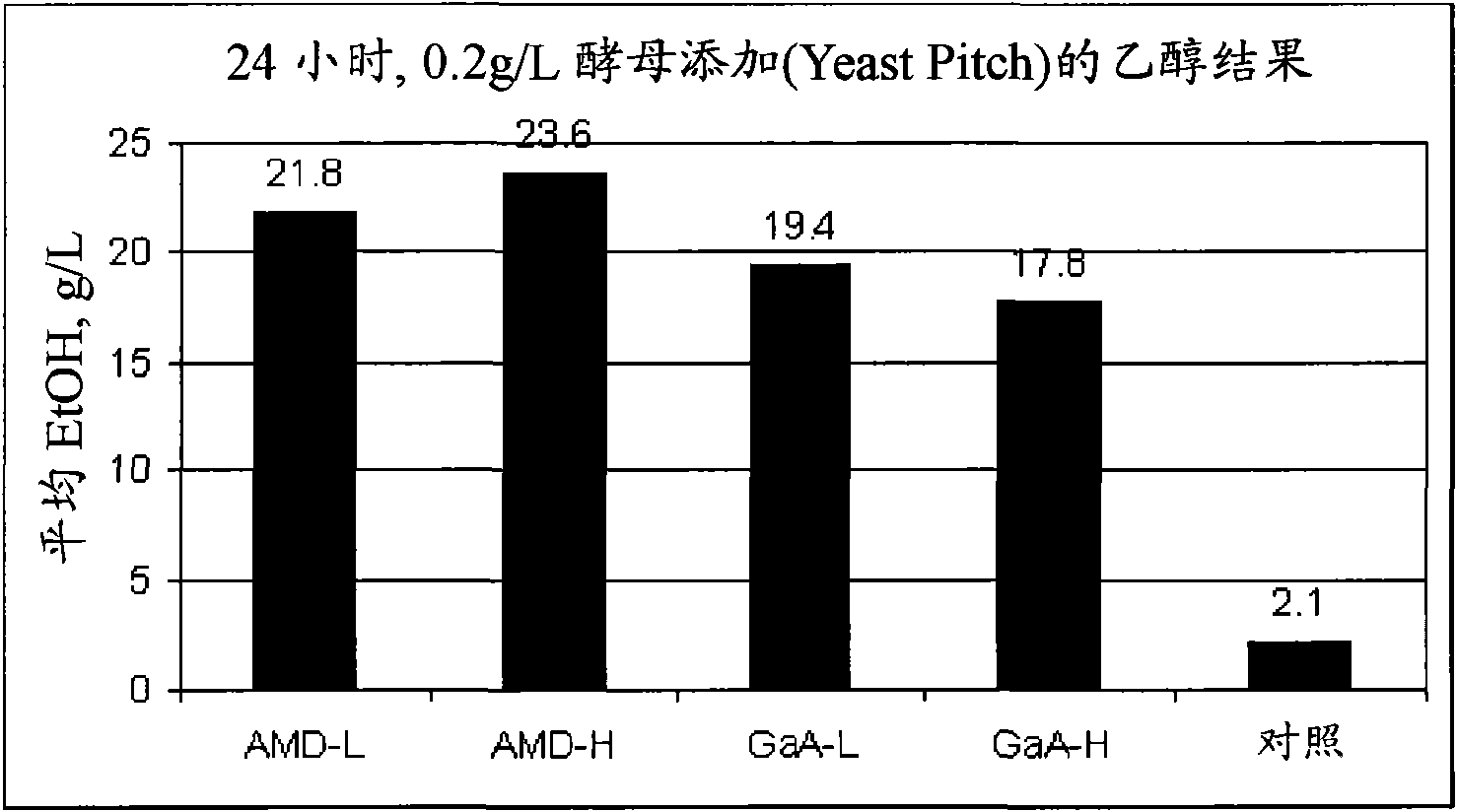

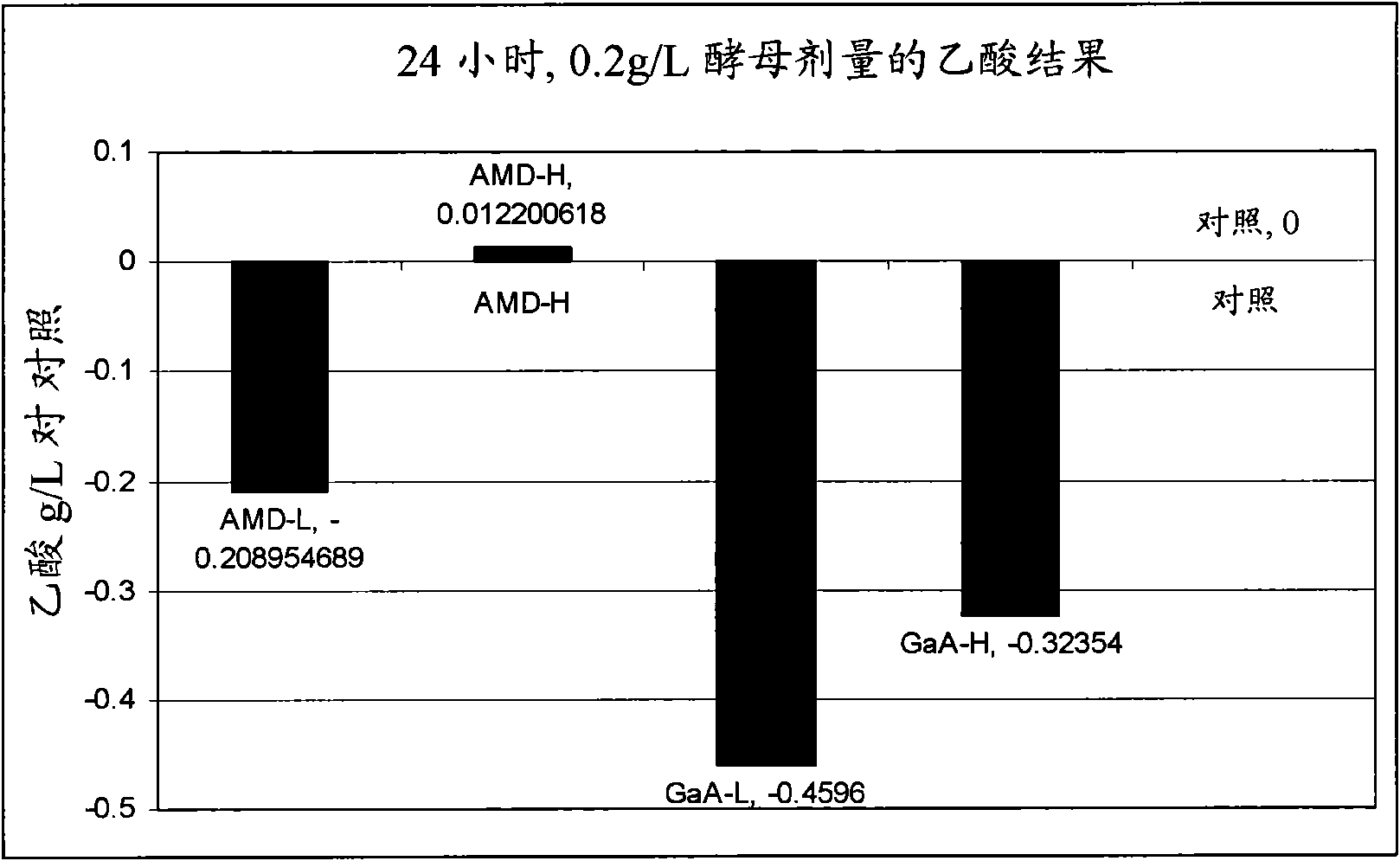

[0350] Preparation / detoxification

[0351] Detoxify filtered, unwashed PCS for 19 h using optimal conditions for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com