Polymeric composition

A composition, polymer technology, used in the field of plastic lenses, optical polymer compositions and the preparation of such compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Dye concentrates were prepared by mixing and grinding the materials listed in Table 14 below:

[0143] Table 14

[0144] Material:

[0145] Additive compositions were prepared by mixing and grinding the above dye concentrates with the materials listed in Table 15:

[0146] Table 15

[0147] Material:

[0148] High molecular weight, low volatility primary antioxidant;

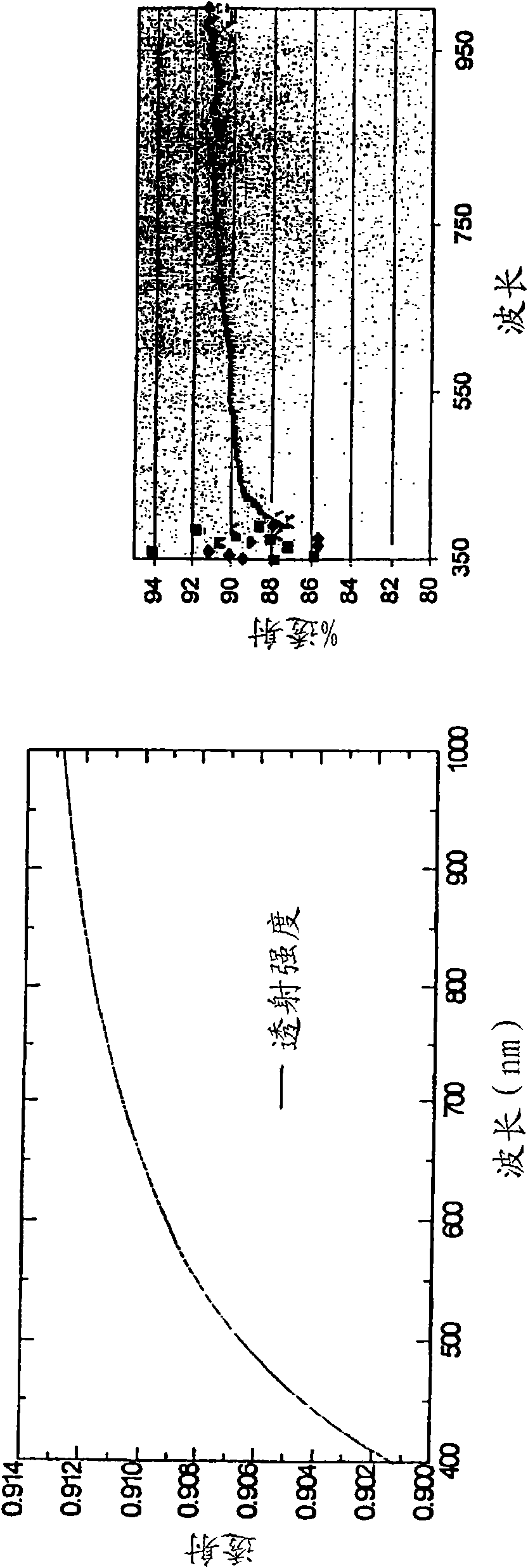

[0149] The polymer compositions shown in Table 16 use APEC TP-0277 polycarbonate resin pellets were prepared with the additive compositions shown in Table 15. The resin pellets were dried in a vacuum oven at 135°C for 4 hours until the water content was below 0.01 wt%. The resin pellets were heated to 135°C, and then the additive composition was added to the resin pellets in a tumbling mixer at a weight ratio of 0.6:99.4. The resin pellets and additive composition were tumble blended for 5 minutes or until the additive composition melted onto and coated the resin p...

Embodiment 2

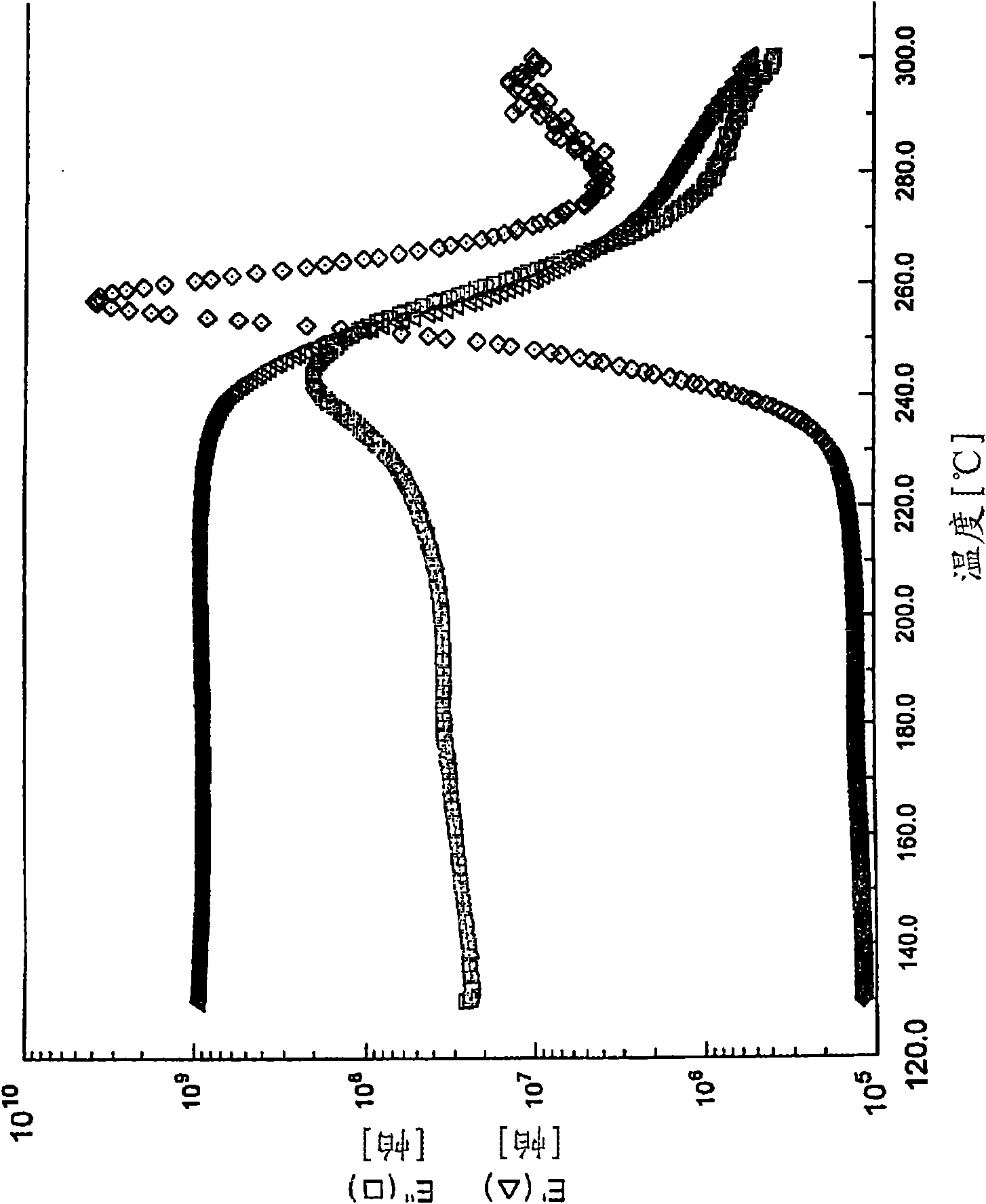

[0183] The polymer composition of Example 1 was molded into strips of size 1 x 14 x 7 mm. The molded sample was heated up to 260° C. at a rate of 2° C. / min, and Tg was measured by DMTA (Dynamic Mechanical Thermal Analysis) under a load of 1 Hz. This test showed that the molded bars were able to withstand short-term temperature peaks up to 260°C and higher without deformation. see results image 3 .

Embodiment 3

[0185] Four polymer compositions 1-4 having the formulations described in Table 17 were injection molded to prepare LED lenses as described below. The high-temperature optical thermoplastic soldering reflow study was carried out on the LED lens, and the results are listed in Table 18.

[0186] Table 17

[0187]

[0188]

[0189] Table 18

[0190] Composition #1

[0191] (Simulation & Actual Soldering Reflow Temperature Study)

[0192] SR = solder reflow A = anneal R rapid anneal

[0193] S = slow annealed U = no annealed

[0194] test

[0195] / R

[0196] / R

[0197] 32.

[0198] R = rapid annealed part at 217°C for 17 min. S = Slowly annealed parts, ramp over 30 minute intervals, hold at 215°C for 30 minutes, then cool for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com