Falling-film tube

A technology of falling film tube and nickel tube, which is applied in the field of highly concentrated lye evaporation device, can solve the problems of long delivery cycle, heating dead zone, uneven heating of lye, etc., and achieve the effect of promoting development and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

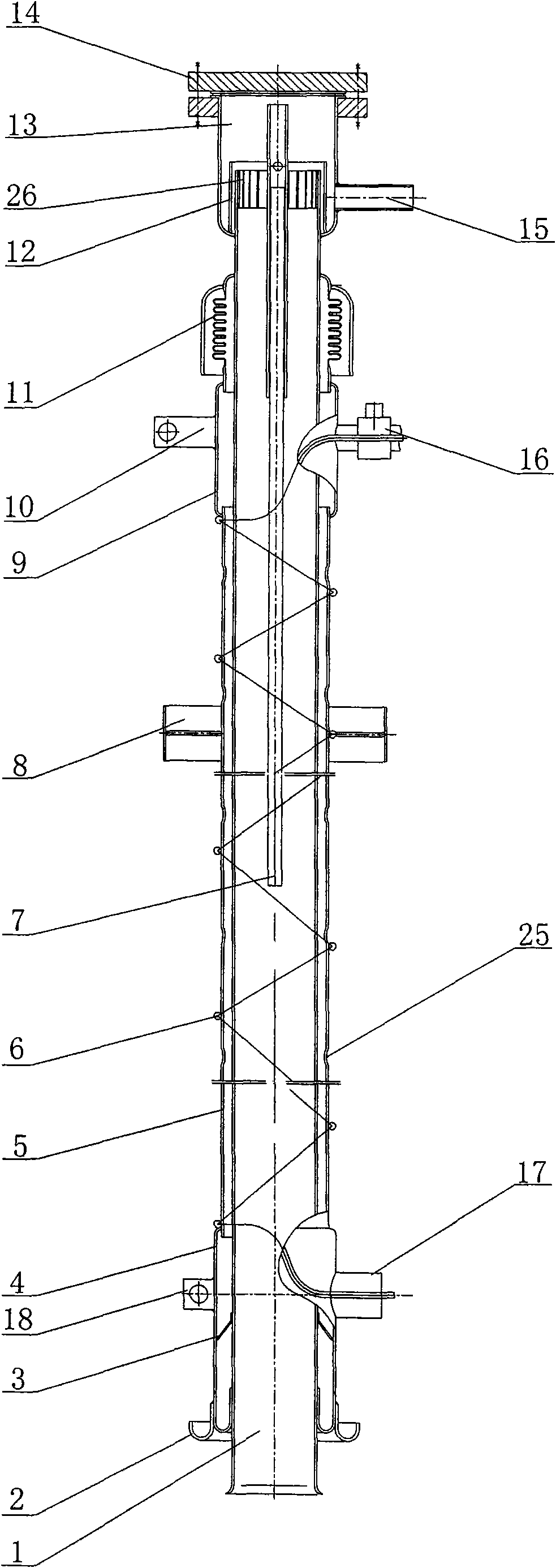

[0028] Such as figure 1 As shown, a falling film tube: including a central nickel tube 1, a bowl-shaped support 2, a lower end body 4, a jacket tube I5, a steam coil 6, a distributor 7, a heat preservation rack 8, a jacket tube II 9, and a compensator 11. Upper body 13 and flange cover 14;

[0029] The lower part of the central nickel tube 1: the central nickel tube 1 is covered by the lower end body 4, the central nickel tube support 3 is provided between the central nickel tube 1 and the lower end body 4, the lower end body 4 is connected with the bowl-shaped support 2, and the lower end body 4 There are lower lifting lugs 18 and molten salt outlet pipes 17 on the top;

[0030] The middle section of the central nickel tube 1: the central nickel tube 1 is covered by the jacket tube I 5, the jacket tube II 9 and the compensator 11, and the two ends of the jacket tube I 5 are respectively connected to the lower end body 4 and the jacket tube II 9 , the other end of the jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com