Method for simply preparing high-purity beta-Elemene

A high-purity technology for elemene, applied in the field of simple preparation of high-purity β-elemene, can solve the problems of high cost, complicated production equipment, and poor extraction stability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

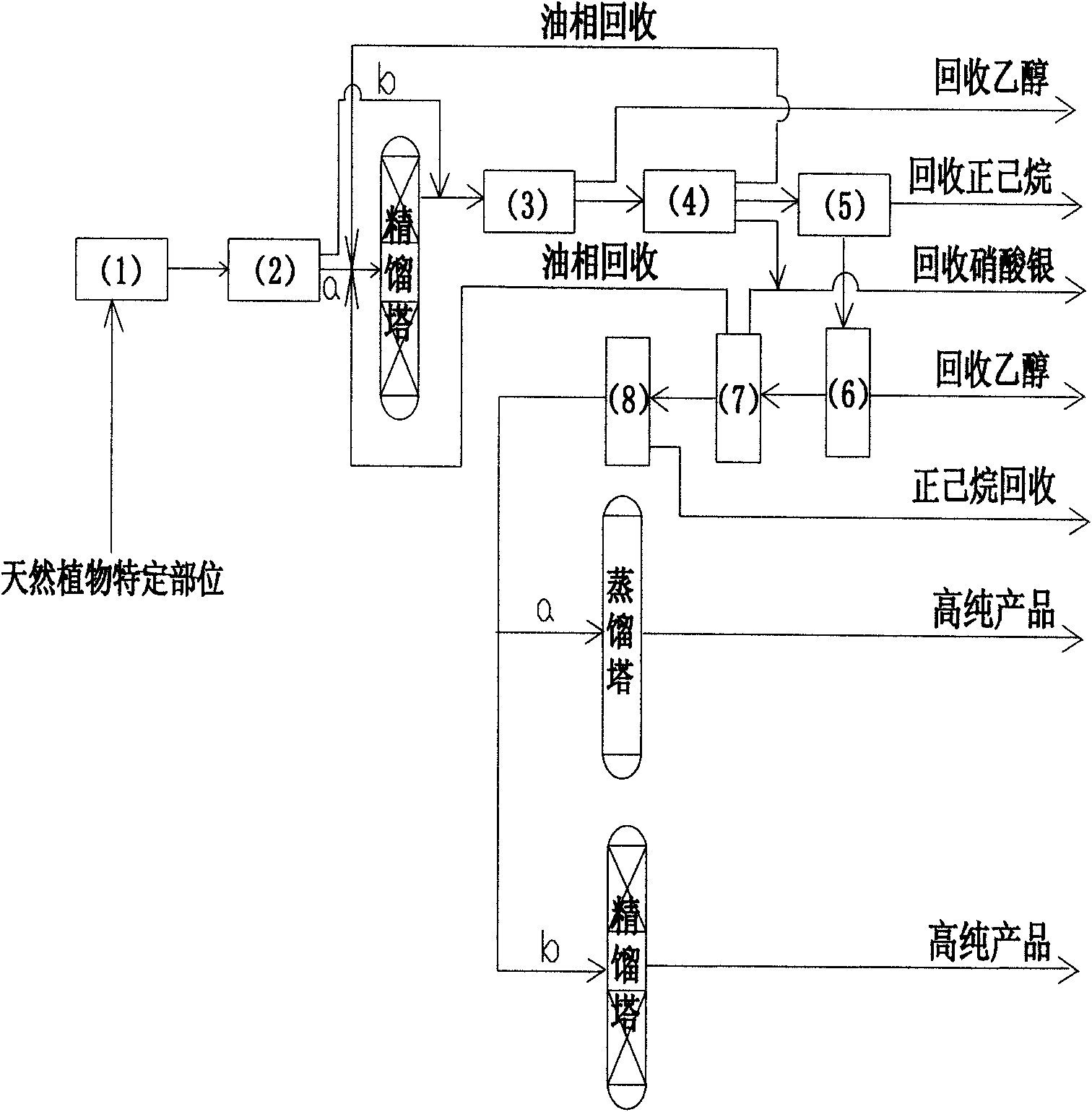

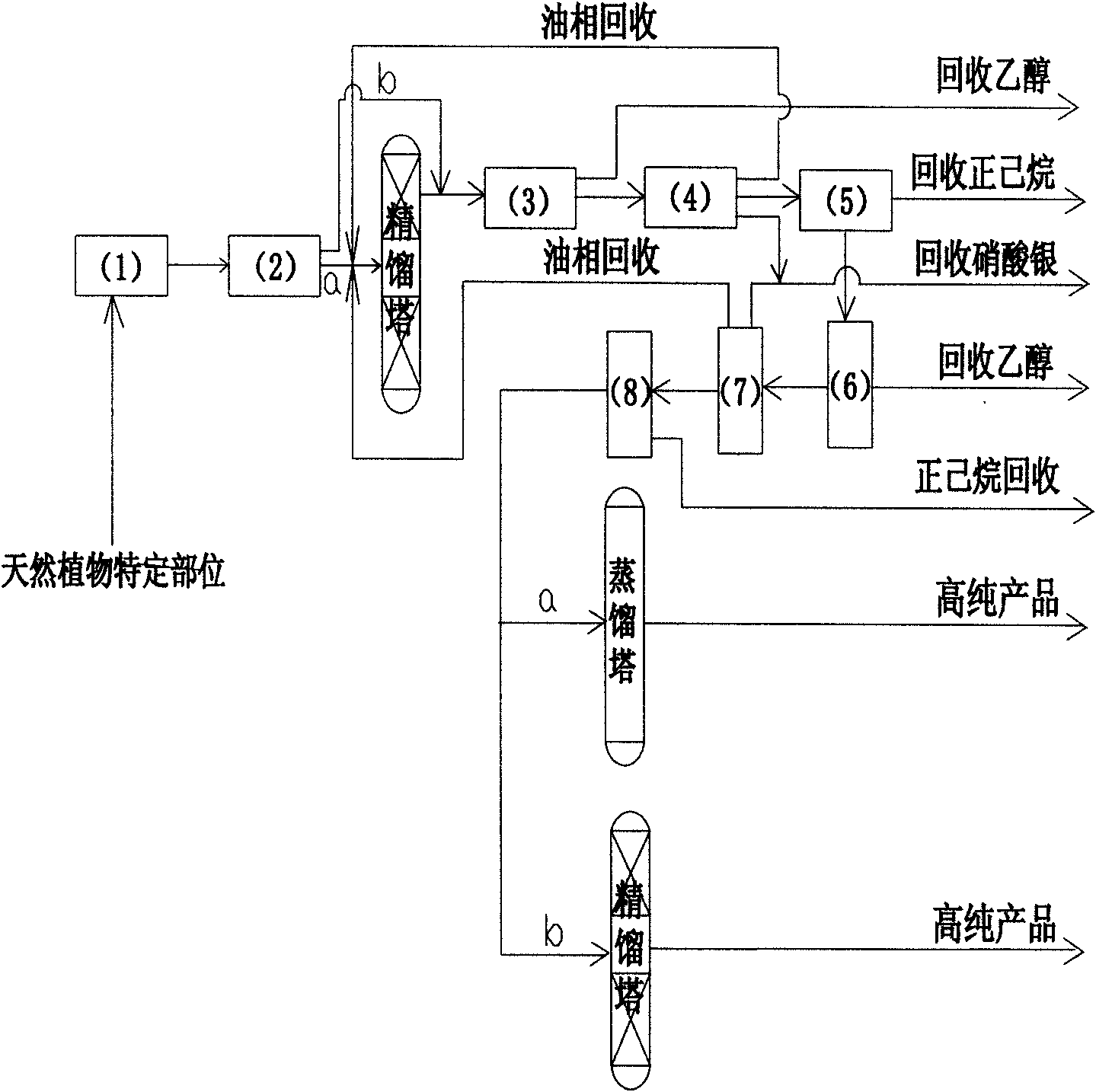

Method used

Image

Examples

Embodiment 1

[0041] A, get the natural herbal medicine curcuma tuber as raw material;

[0042] B, the medicinal material Zedoary is steam-distilled to obtain Zedoary volatile oil, wherein the content of β-elemene is 6.0%;

[0043] c, put the raw material obtained in b into the rectifying tower still to carry out rectification, the control vacuum degree is 5~6mm Hg, the temperature of the tower still is 123 ℃~124 ℃, when the reflux ratio is 1: 1, the removal temperature is at Impurity fractions below 75°C; control the reflux ratio to 3:1, collect fractions at a temperature of 77°C to 82°C, and obtain β-elemene with a content of 23.5%.

[0044] d. The 23.5% β-elemene obtained in c was extracted three times with 80% ethanol aqueous solution with double volume concentration, and the upper oil phase was collected.

[0045] e, the oil phase obtained in step d is extracted three times with an aqueous solution having an equal volume concentration of 1.5 mol / L silver nitrate, the lower layer of th...

Embodiment 2

[0048] a, taking the fresh leaves of natural plant Javanese citronella as raw material;

[0049] b. The medicinal material Javanese citronella is steam-distilled to obtain Javanese volatile oil, wherein the content of β-elemene is 5.0%;

[0050] c, put the raw material obtained in b into rectification tower still and carry out rectification, control vacuum tightness is 2~3mm Hg, the temperature of tower still is 116 ℃~117 ℃, when reflux ratio is 1: 1, removal temperature is in The impurity fraction below 75°C; the reflux ratio is controlled to be 3:1, and the fraction at a temperature of 78°C to 81°C is collected to obtain β-elemene with a content of 16.0%.

[0051] d. The 16.0% β-elemene obtained in c was extracted three times with a 70% ethanol aqueous solution with a quadruple volume concentration, and the upper oil phase was collected.

[0052] e, the oil phase obtained in step d is extracted three times with an aqueous solution of 2.5 mol / L silver nitrate with an equal v...

Embodiment 3

[0055] a, taking the fresh leaves of natural plant Solidago as raw material;

[0056] b. Obtaining Solidago volatile oil through supercritical extraction of the leaves of Solidago, wherein the content of β-elemene is 14.3%;

[0057] c, put the raw material obtained in b into the rectification tower still for rectification, control the vacuum to be 6-7mm Hg, the temperature of the tower still is 123-124°C, when the reflux ratio is 1:1, the removal temperature is 75 The impurity fraction below ℃; the reflux ratio is controlled to be 4:1, and the fractions with a temperature of 79°C to 82°C are collected to obtain β-elemene with a content of 40.6%.

[0058] d. The 40.6% β-elemene obtained in c was extracted three times with 60% ethanol aqueous solution with a triple volume concentration, and the upper oil phase was collected.

[0059] e, the oil phase obtained in step d is extracted three times with an aqueous solution having an equal volume concentration of 2.0 mol / L silver nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com