Method for directly preparing 1,3-dichloro-2-propanol by catalyzing glycerol with sulfur and zirconium

A sulfur-zirconium catalyzed glycerin, direct technology, applied in chemical instruments and methods, introduction of halogen preparation, physical/chemical process catalysts, etc., can solve the problems that the catalyst cannot be recycled and reused, does not conform to the development of green chemistry, and the post-processing of products is troublesome. , to achieve the effect of reducing the pre-reaction time, mild reaction conditions and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

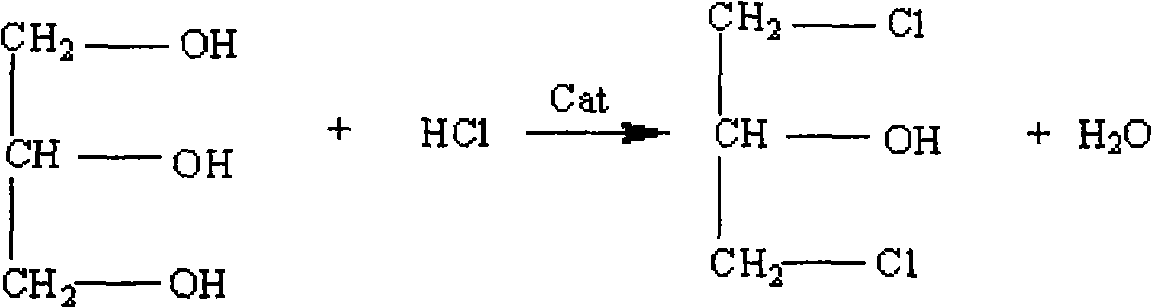

Image

Examples

Embodiment 1

[0019] Add 8.149 g of glycerin into the four-neck flask, add 0.256 g of catalyst sulfur zirconium under stirring, heat to reflux, and measure 9 ml of hydrochloric acid with a mass fraction of 36%. The temperature of the reaction system was raised to 100°C, and hydrochloric acid was added dropwise to the four-necked flask at a constant pressure. The dropwise addition was completed within 0.5 hours. When no water came out of the fractionating column, the reaction was stopped, the temperature was lowered, the catalyst was recovered, and the reaction product was distilled under reduced pressure to obtain 1,3-dichloro-2-propanol, the yield of 1,3-dichloro-2-propanol reaches 90.5%.

Embodiment 2

[0021] Add 24.447g of glycerin into the four-neck flask, add 1.222g of catalyst zirconium sulfur under stirring, heat to reflux, and measure 55ml of hydrochloric acid with a mass fraction of 30%. The temperature of the reaction system was raised to 100°C, and hydrochloric acid was added dropwise to the four-necked flask at a constant pressure. The dropwise addition was completed within 0.75 hours. When no water came out of the fractionating column, the reaction was stopped, the temperature was lowered, the catalyst was recovered, and the reaction product was distilled under reduced pressure to obtain 1,3-dichloro-2-propanol, the yield of 1,3-dichloro-2-propanol reaches 91.7%.

Embodiment 3

[0023] Add 48.160 g of glycerin into the four-neck flask, add 3.371 g of catalyst sulfur zirconium under stirring, heat to reflux, and measure 130 ml of hydrochloric acid with a mass fraction of 38%. The temperature of the reaction system was raised to 100°C, and hydrochloric acid was added dropwise to the four-necked flask at constant pressure. The dropwise addition was completed within 1 hour. When no water came out of the fractionating column, the reaction was stopped, the temperature was lowered, the catalyst was recovered, and the reaction product was distilled under reduced pressure to obtain 1,3-dichloro-2-propanol, the yield of 1,3-dichloro-2-propanol reaches 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com