Process for backblowing and deashing through bag-type dust remover by blast furnace dry method

A bag filter and blast furnace technology, applied in the field of metallurgy, can solve the problems of reducing the operation cost of bag filter, insufficient nitrogen supply, unstable pressure, etc., and achieve the effect of reducing operation cost, reducing input and satisfying calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

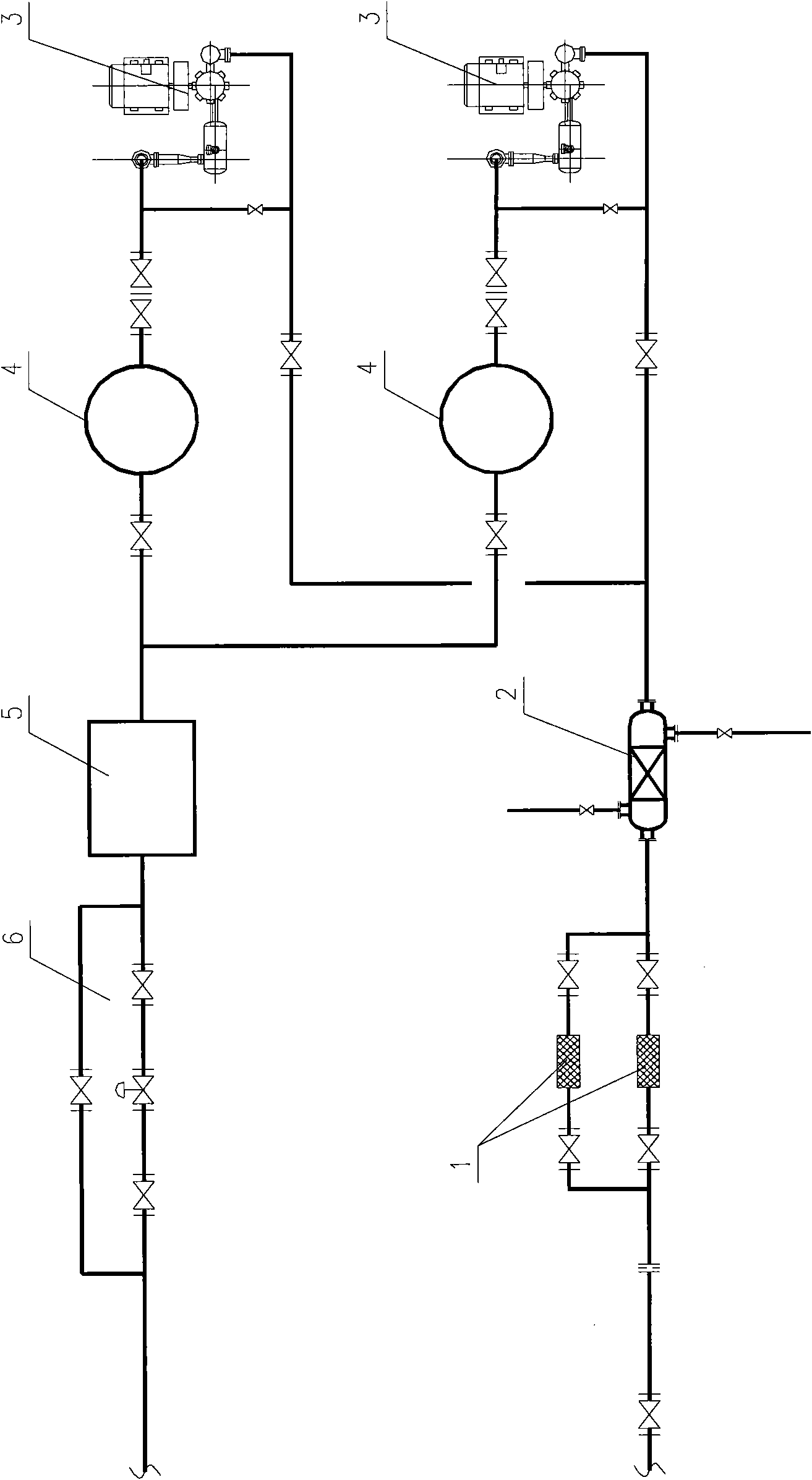

[0022] The present invention mainly uses the clean blast furnace gas after dust removal by the blast furnace bag filter to replace the nitrogen to carry out back blowing and soot cleaning on the cloth bag. gas requirements. In order to further set forth the technical means and effects taken for the content of the present invention and reach the intended purpose of the invention, the detailed description is as follows in conjunction with the accompanying drawings:

[0023] refer to figure 1 As shown, the equipment involved in this process mainly includes: gas filter 1, cooler 2, gas compressor 3, buffer tank 4, gas dehydrator 5 and pressure regulating valve group 6. The clean blast furnace gas sent by the bag dust collector is further deashed through the filter, and after cooling, pressurization, dehydration and pressure regulation, it is used as a gas source to blow back the blast furnace bag filter.

[0024] The above steps specifically include:

[0025] a. Dust removal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com