Device and method for preventing copper wires from being oxidized in production of enameled wires

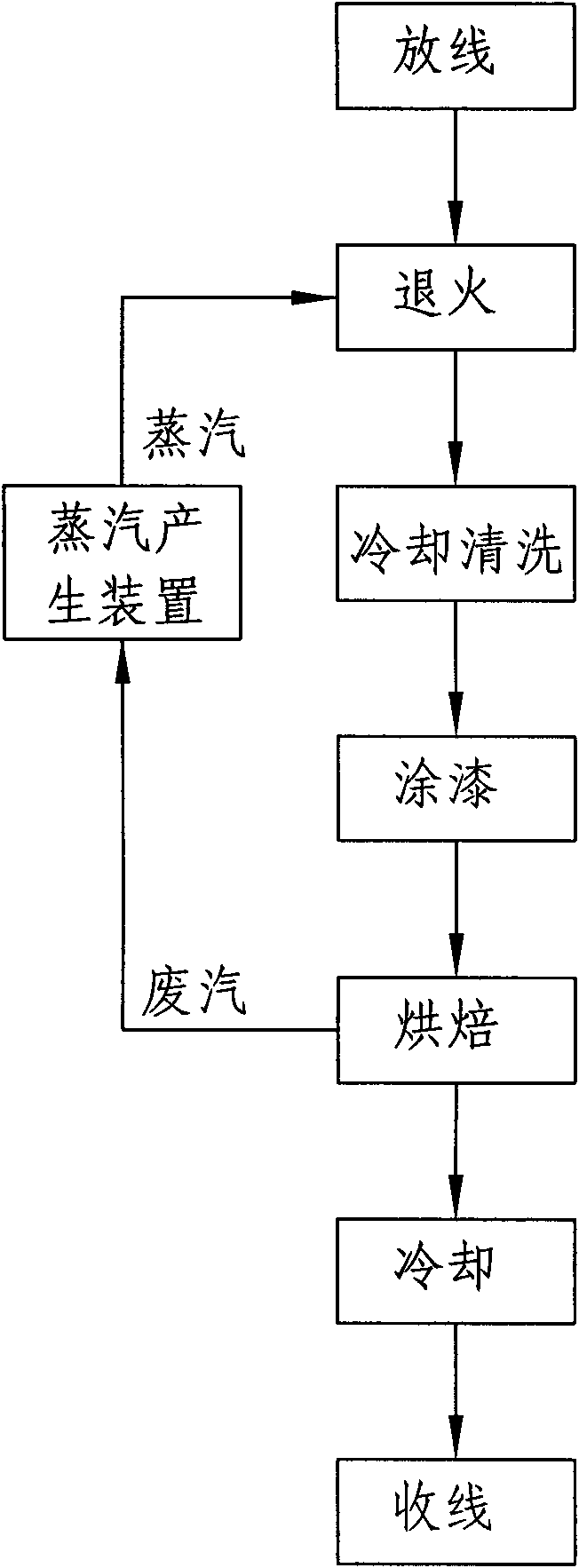

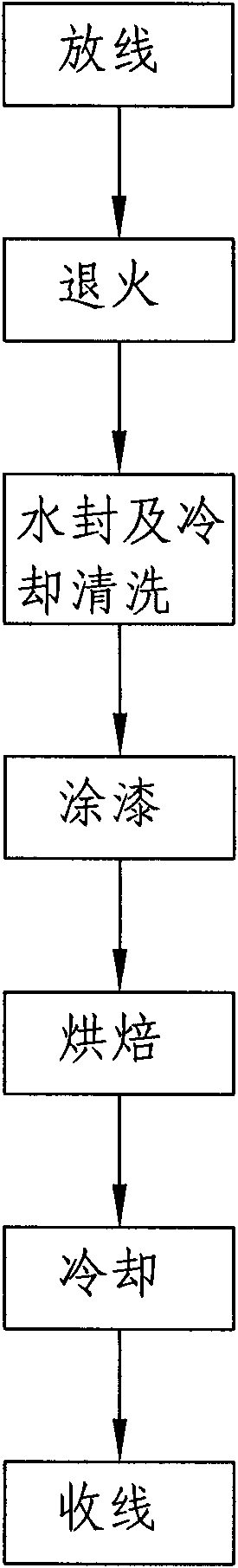

An enameled wire and copper wire technology, which is applied in the field of equipment to prevent copper wire oxidation, can solve problems such as unstable steam supply, and achieve the effects of simplifying production equipment, brightening quality, and reducing installation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

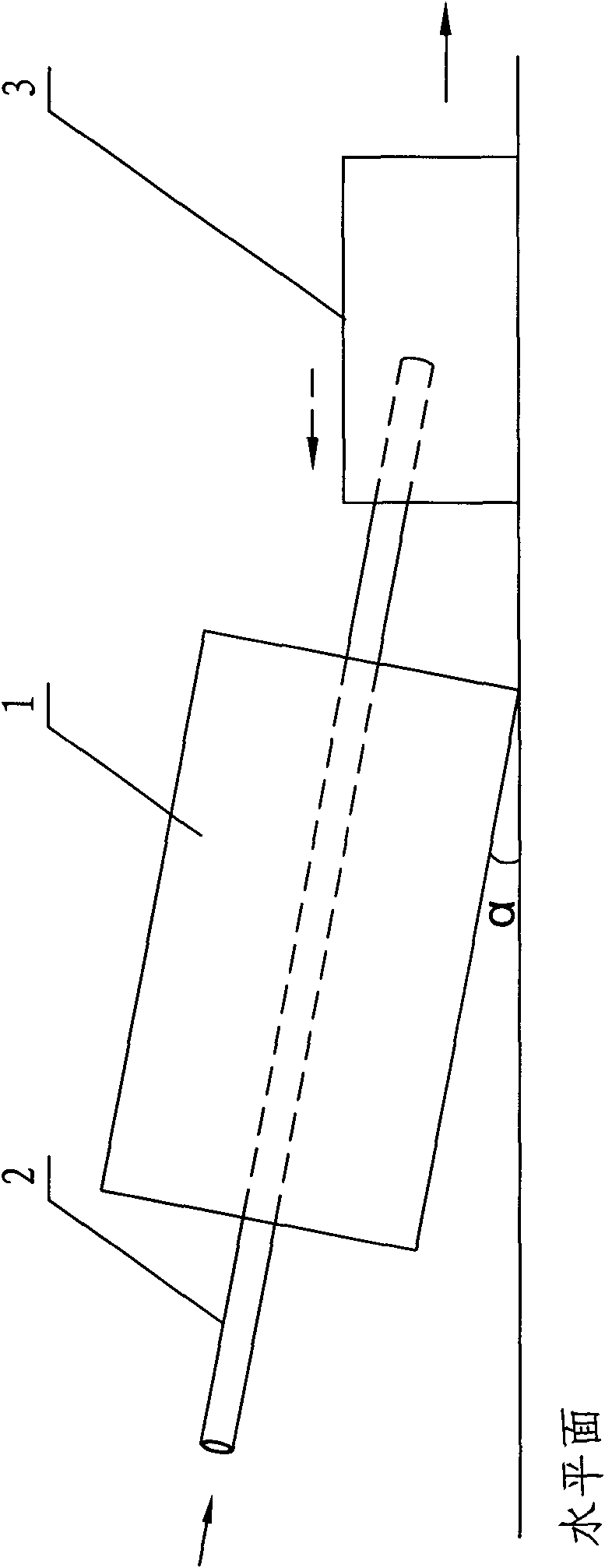

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] see figure 2 , image 3 , the equipment for preventing oxidation of copper wires in the production of enameled wires, including an annealing furnace 1 and an annealing pipeline 2 running through it, and a water tank 3 is arranged at the copper wire outlet end of the annealing pipeline. When working, the copper wire comes out of the annealing pipe in the annealing furnace and immediately passes into the water tank filled with deionized water. The temperature of the copper wire itself is stable and equal to the temperature of the annealing furnace. Enter the annealing furnace along the inclined annealing pipe to protect the copper wire from oxidation. The annealing pipe and the horizontal plane are set at an angle between 20° and 45° to prevent deionized water from flowing into the annealing furnace along the annealing pipe; at the same time, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com