Heat accumulating type storage tank for absorbing natural gas

A natural gas and storage tank technology, applied in the field of regenerative natural gas adsorption storage tanks, can solve problems such as natural gas recovery, and achieve the effects of accelerating mass and heat transfer, increasing storage and transportation efficiency, and accelerating inflation and deflation rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the utility model is further described:

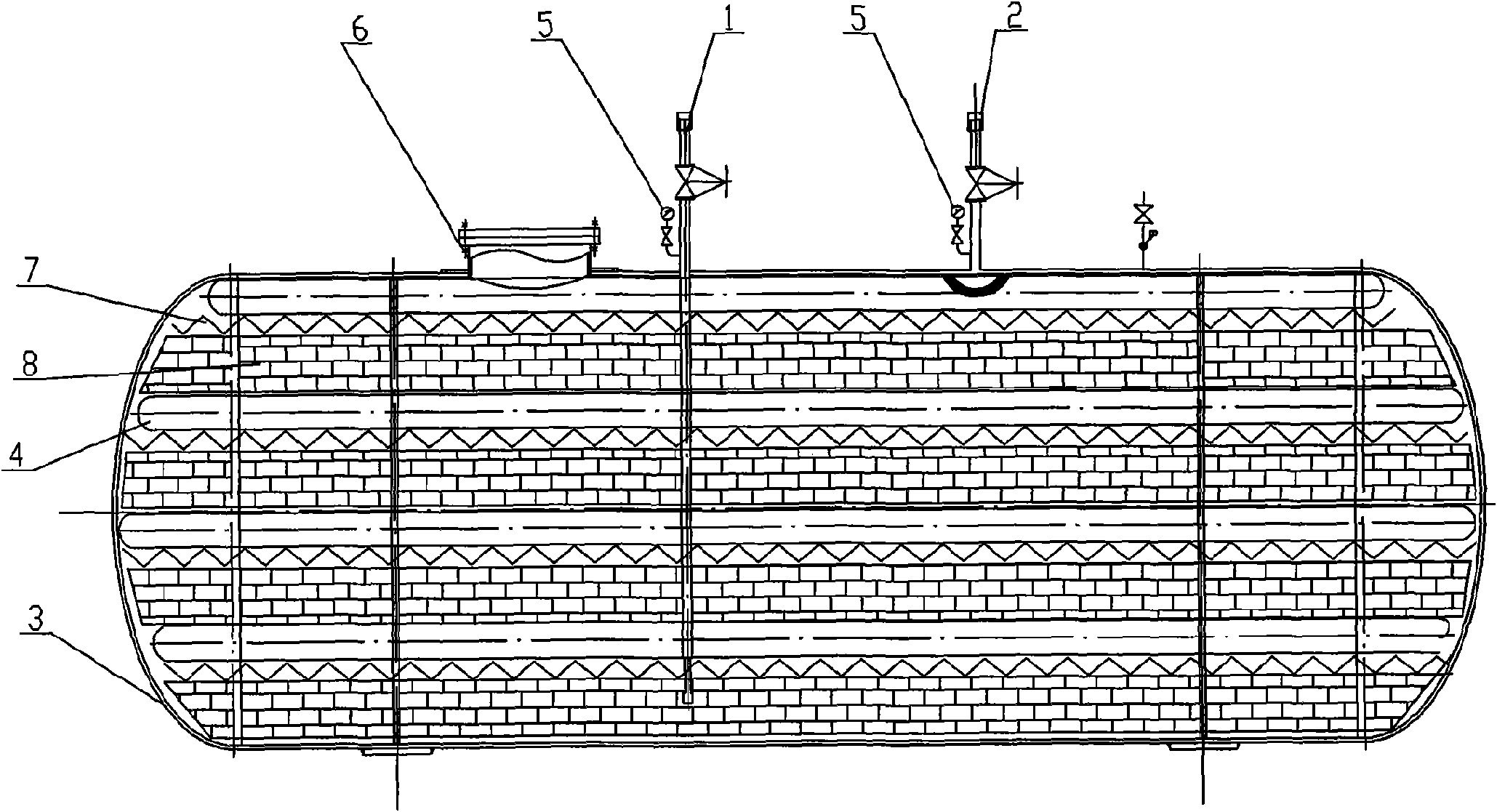

[0013] The regenerative natural gas adsorption storage tank includes a tank body 3 with a manhole 6 at the upper end of the tank body 3. The manhole 6 is used to load and unload the pressure-resistant metal pipe 4, metal mesh 7, and carbonaceous natural gas adsorbent 8. A metal mesh 7 is arranged between adjacent two layers of natural gas adsorbents 8 in the body 3, and the metal mesh 7 plays a role in supporting the natural gas adsorbent and making the natural gas evenly distributed into the tank body, and the metal mesh 7 is inflated and deflated It plays the role of accelerating mass transfer and heat transfer, and the metal tubes 4 are placed in rows on the metal mesh 7 at intervals. The metal tubes 4 are equipped with heat storage substances, and the heat storage substances are composed of: Ca(NO 3 ) 2 4H 2 O, Na 2 HPO 4 ·7H 2 O, CH 4 COONa·4H 2 O, Na 2 S 2 o 3 ·5H 2 O, Na 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com