Whole set smelting device for ferrotitanium series product

A series of products and complete sets of equipment technology, applied in the field of metallurgical titanium-iron alloys, can solve the problems of uneven heating of materials, low raw material efficiency, low heating efficiency, etc., and achieve the effect of short heating time, high heating efficiency and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

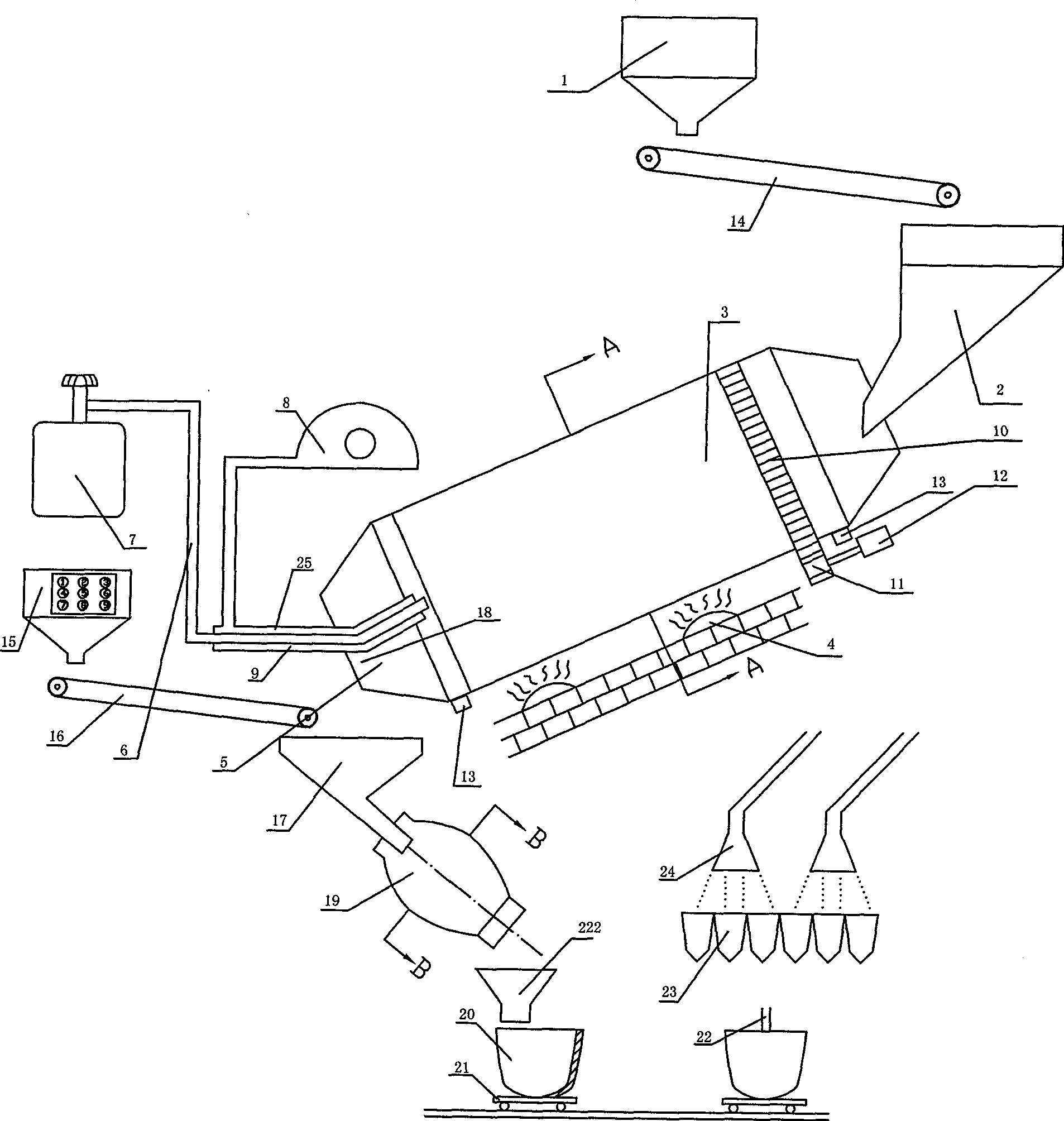

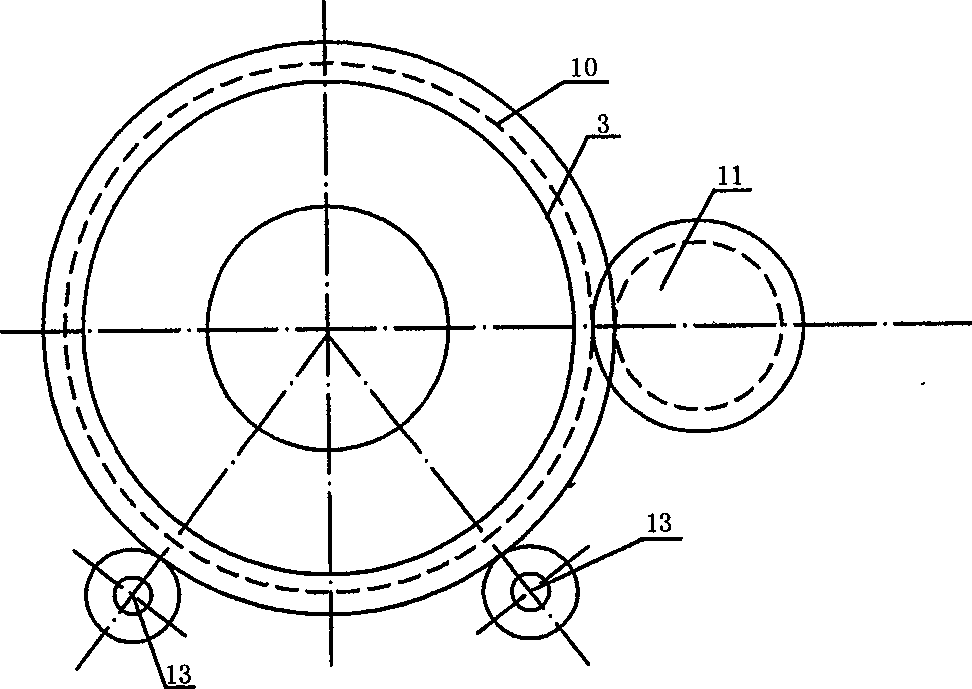

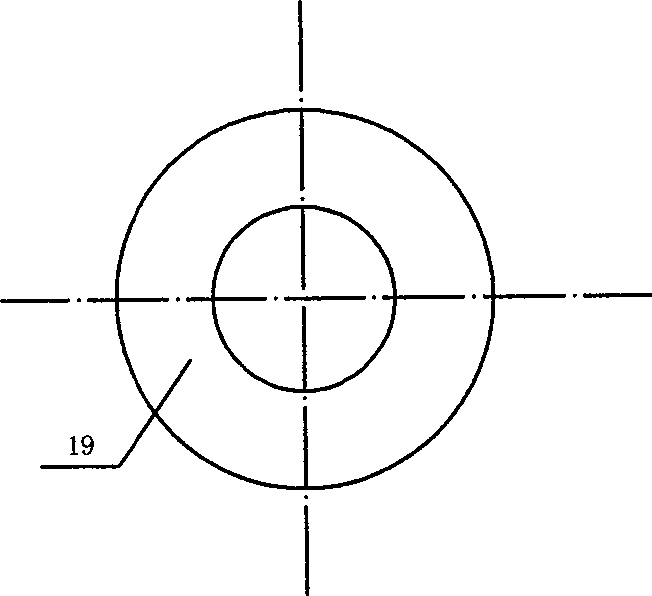

[0028] A complete set of smelting equipment for ferrotitanium series products, including a feeding bin 1, a docking bin 2 connected to the feeding bin 1, a rapid heating device connected to the docking bin 2, a mixing device and a smelting device. The rapid heating device includes one end connected to the The rotary furnace 3 connected to the docking warehouse 2, the rotary furnace 3 is provided with a driving device for driving the rotary furnace 3 to rotate and a heating furnace 4 for heating the rotary furnace 3, and the other end of the rotary furnace 3 is provided There is a combustion chamber 5, and the outside of the combustion chamber 5 is provided with a gas generator 7 communicated with a gas pipe 6, and a hot air blower 8 is communicated with the combustion chamber 5 through an outer ring pipe 9 of the gas pipe 6. The rotary furnace 3 is provided with a converter ring gear 10 , and the converter ring gear 10 is connected to a driving device outside the rotary furnace...

Embodiment 2

[0031] A complete set of smelting equipment for ferrotitanium series products, including a feeding bin 1, a docking bin 2 connected to the feeding bin 1, a rapid heating device connected to the docking bin 2, a mixing device and a smelting device. The rapid heating device includes one end connected to the The rotary furnace 3 connected to the docking warehouse 2, the rotary furnace 3 is provided with a driving device for driving the rotary furnace 3 to rotate and a heating furnace 4 for heating the rotary furnace 3, and the other end of the rotary furnace 3 is provided There is a combustion chamber 5, and the outside of the combustion chamber 5 is provided with a gas generator 7 communicated with a gas pipe 6, and a hot air blower 8 is communicated with the combustion chamber 5 through an outer ring pipe 9 of the gas pipe 6. The rotary furnace 3 is provided with a converter ring gear 10 , and the converter ring gear 10 is connected to a driving device outside the rotary furnace...

Embodiment 3

[0036] A complete set of smelting equipment for ferrotitanium series products, including a feeding bin 1, a docking bin 2 connected to the feeding bin 1, a rapid heating device connected to the docking bin 2, a mixing device and a smelting device. The rapid heating device includes one end connected to the The rotary furnace 3 connected to the docking warehouse 2, the rotary furnace 3 is provided with a driving device for driving the rotary furnace 3 to rotate and a heating furnace 4 for heating the rotary furnace 3, and the other end of the rotary furnace 3 is provided There is a combustion chamber 5, and the outside of the combustion chamber 5 is provided with a gas generator 7 communicated with a gas pipe 6, and a hot air blower 8 is communicated with the combustion chamber 5 through an outer ring pipe 9 of the gas pipe 6. The rotary furnace 3 is provided with a converter ring gear 10 , and the converter ring gear 10 is connected to a driving device outside the rotary furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com