Silicon resonation type pressure sensor based on synovial membrane differential structure and manufacturing method thereof

A pressure sensor and resonant technology, applied in the field of sensors, can solve the problems of complex manufacturing process and layout of silicon resonant pressure sensors, and achieve the effects of convenient structure and layout design, increased sensitivity, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

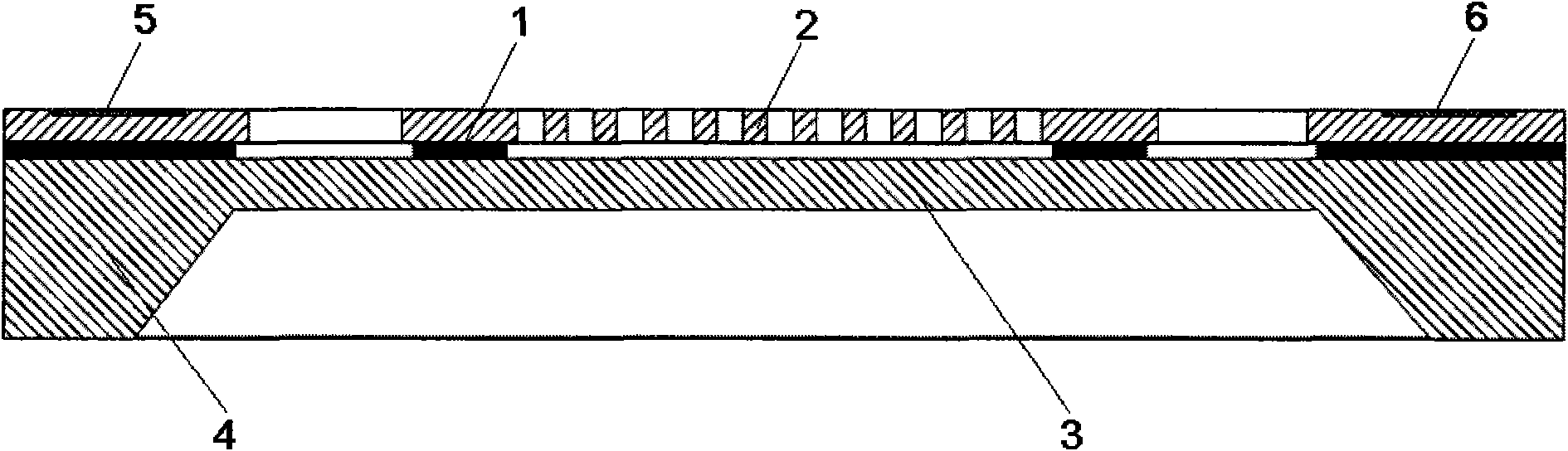

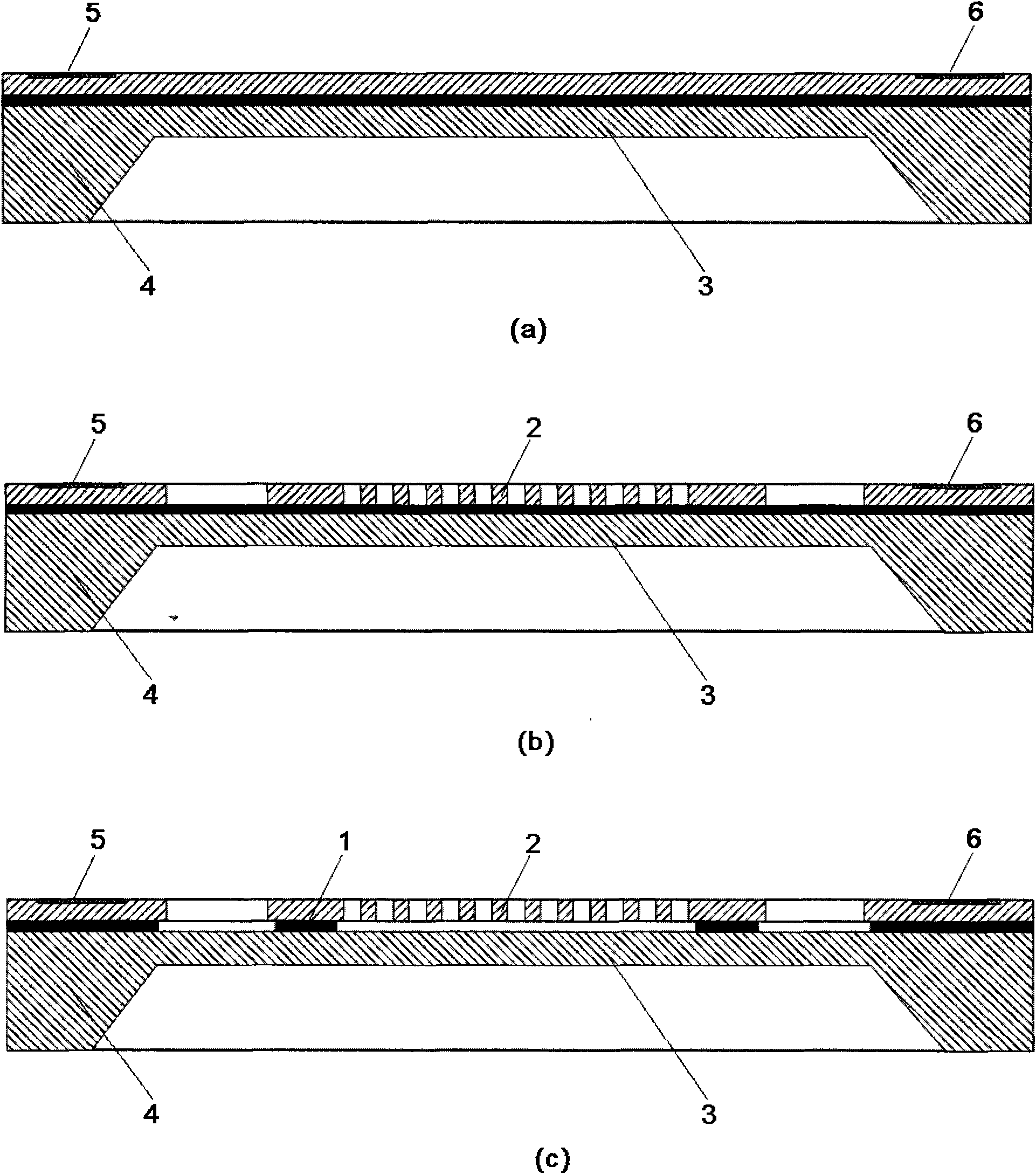

[0043] refer to figure 1 , Figure 5 , the silicon resonant pressure sensor based on the synovial film differential structure in this embodiment mainly includes four parts: a resonator 2, a support column 1, a pressure sensitive diaphragm 3 and a frame 4, wherein the upper part of the frame 4 is connected to the four sides of the pressure sensitive diaphragm 3 Connected, the lower part is formed with a cavity corresponding to the pressure sensitive diaphragm 3, so that the gas to be measured is in contact with the pressure sensitive diaphragm 3 through the cavity. The support column 1 is located on the upper surface of the pressure sensitive diaphragm 3 , and the resonator 2 is suspended on the upper surface of the pressure sensitive diaphragm 3 through the support column 1 and the frame 4 .

[0044] The pressure sensitive diaphragm 3 has a square structure and no silicon islands on the lower surface.

[0045] The support columns 1 are arranged symmetrically on the diagonal of...

Embodiment 2

[0055] refer to figure 1 , Figure 6 In this embodiment, the silicon resonant pressure sensor based on the synovial film differential structure mainly includes four parts: a resonator 2, a support column 1, a pressure sensitive diaphragm 3 and a frame 4, wherein the upper part of the frame 4 is connected to the four sides of the pressure sensitive diaphragm 3 , a cavity is formed at the lower part corresponding to the pressure-sensitive diaphragm 3, so that the gas to be measured is in contact with the pressure-sensitive diaphragm 3 through the cavity. The support column 1 is located on the upper surface of the pressure sensitive diaphragm 3 , and the resonator 2 is suspended on the upper surface of the pressure sensitive diaphragm 3 through the support column 1 and the frame 4 .

[0056] The pressure sensitive diaphragm 3 has a square structure and no silicon islands on the lower surface.

[0057] The support column 1 is symmetrically arranged on the central symmetry axis o...

Embodiment 3

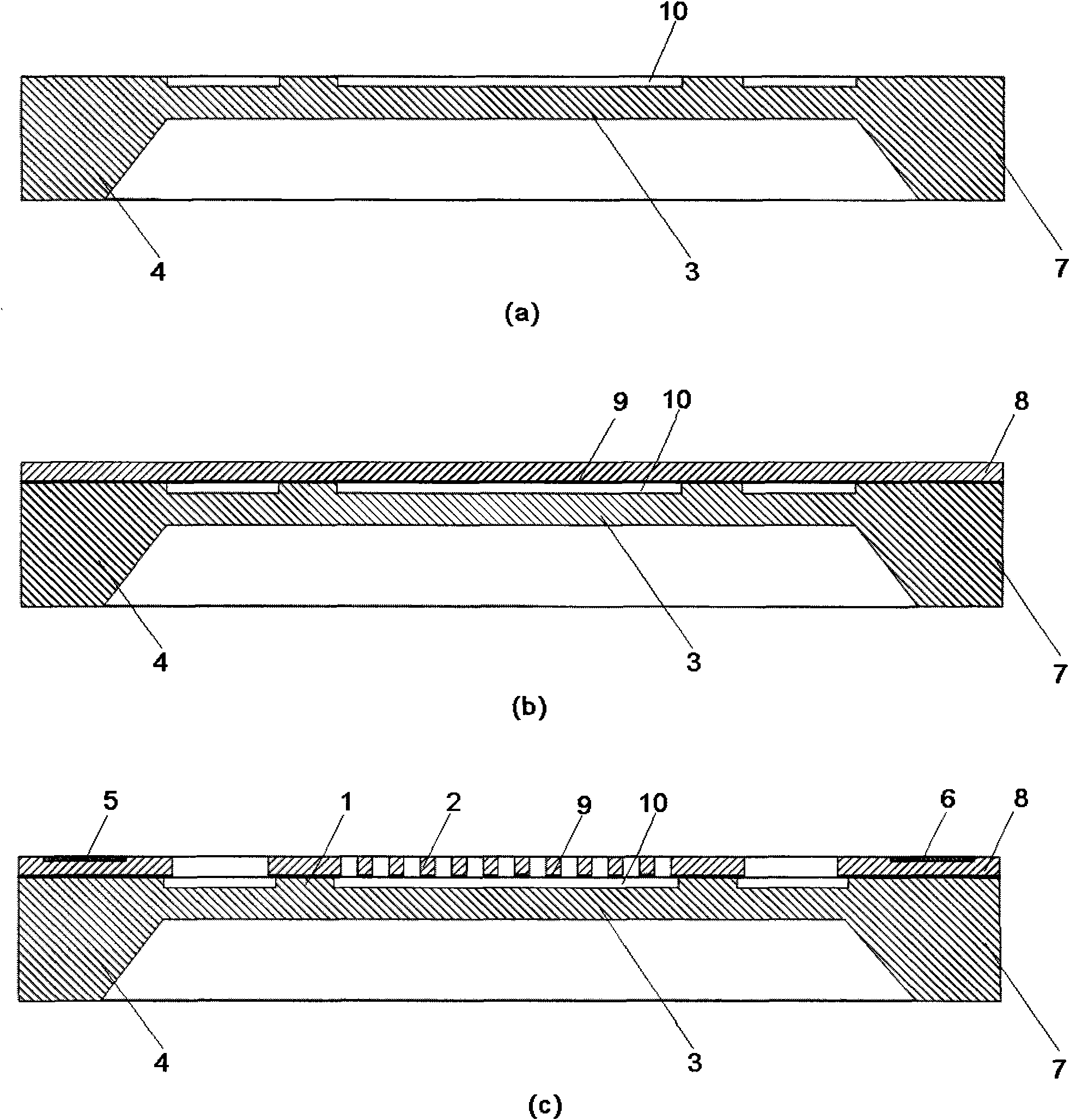

[0067] refer to figure 1 , Figure 7 In this embodiment, the silicon resonant pressure sensor based on the synovial film differential structure mainly includes four parts: a resonator 2, a support column 1, a pressure sensitive diaphragm 3 and a frame 4, wherein the upper part of the frame 4 is connected to the four sides of the pressure sensitive diaphragm 3 , a cavity is formed at the lower part corresponding to the pressure-sensitive diaphragm 3, so that the gas to be measured is in contact with the pressure-sensitive diaphragm 3 through the cavity. The support column 1 is located on the upper surface of the pressure sensitive diaphragm 3 , and the resonator 2 is suspended on the upper surface of the pressure sensitive diaphragm 3 through the support column 1 and the frame 4 .

[0068] The pressure-sensitive diaphragm 3 has a square structure, and the lower surface has polygonal silicon islands.

[0069] The support column 1 is arranged symmetrically on the central symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com