Luminescent device and manufacturing method thereof

A technology of light-emitting devices and light-emitting layers, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as damage to the light-emitting performance of the LED structure 100, and overcome thermal expansion and lattice mismatch. The effect of throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

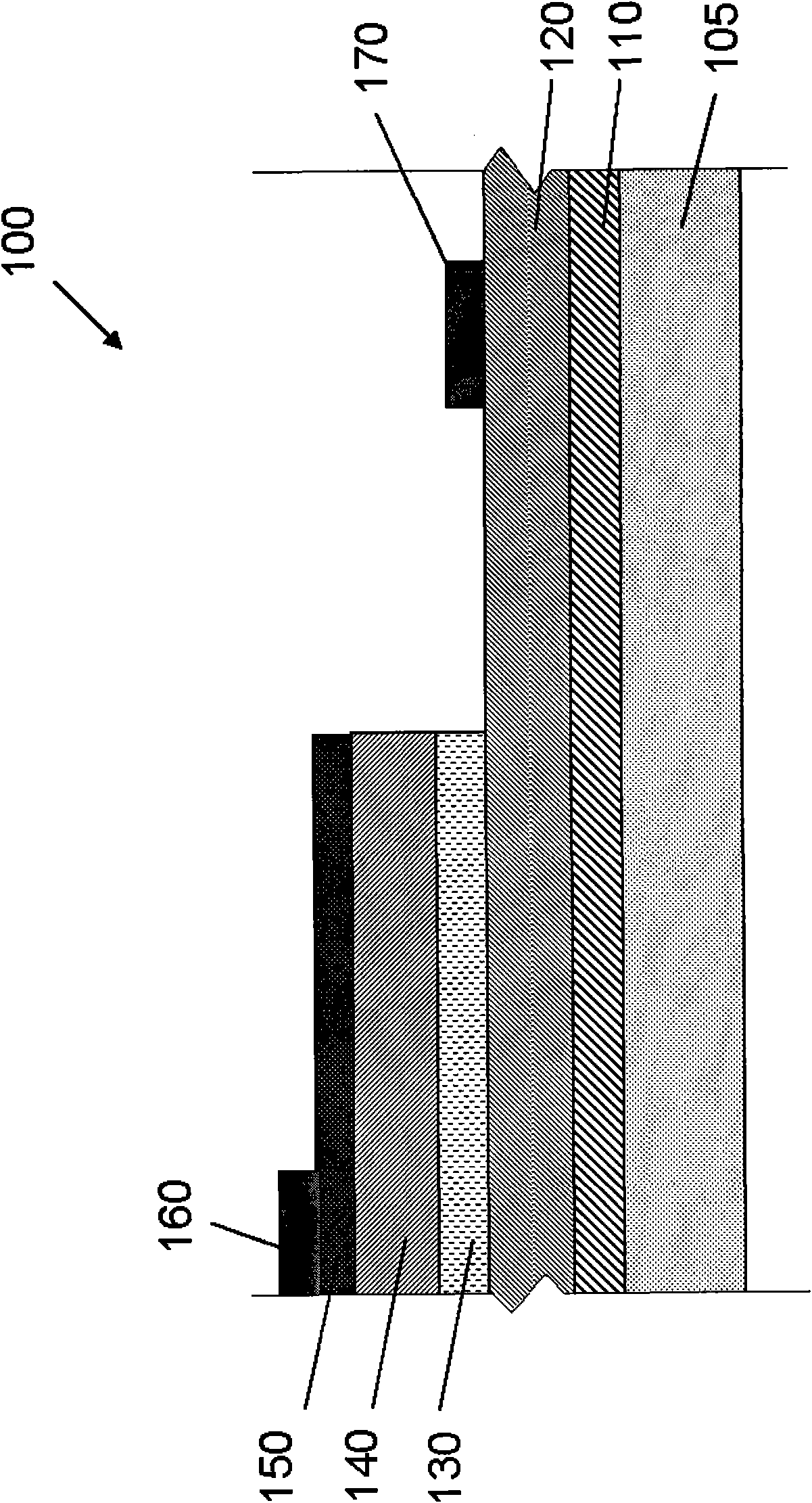

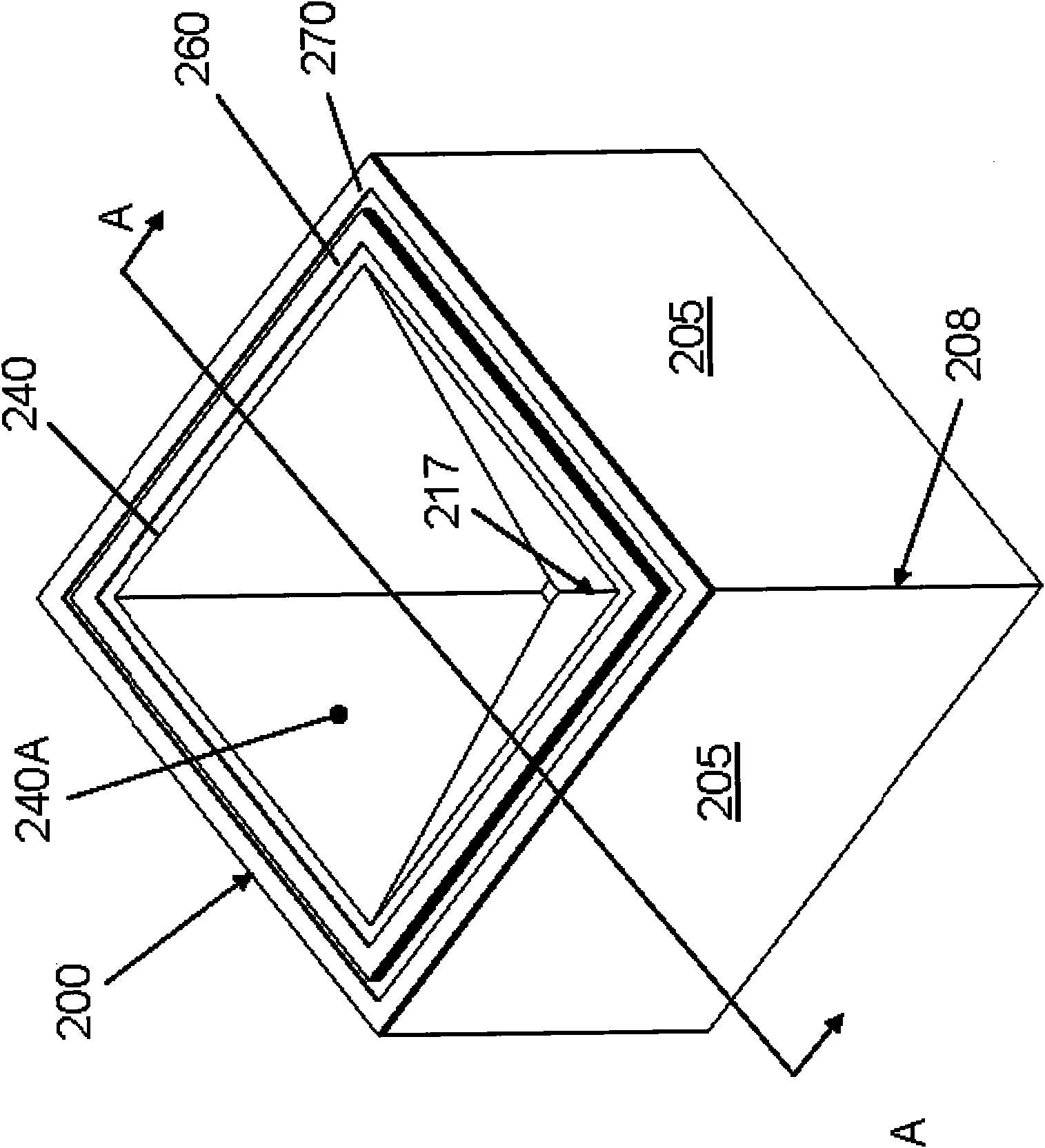

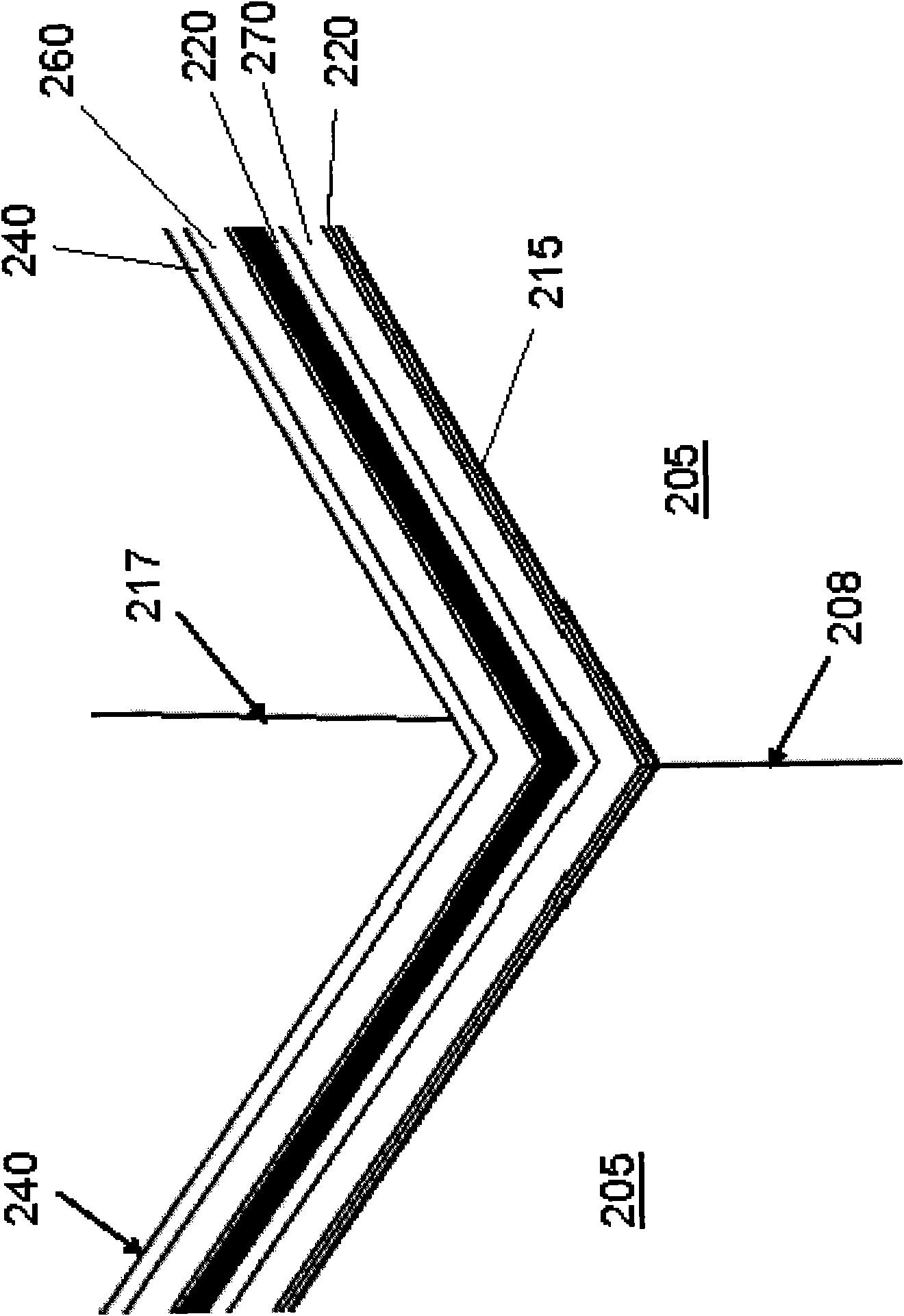

[0048] refer to Figure 2A to Figure 3C , having an upper surface 207 ( Figure 3B ) The light emitting device 200 is formed on the substrate 205. The light emitting device 200 includes a trench 210 in the substrate 205 below the upper surface 207 . The trench 210 has one or more trench surfaces 213 ( Figure 3B ). Trench 210 may also have a bottom surface 219 parallel to upper surface 207 . The area of the bottom surface 219 can be kept less than 20% of one of the trench surfaces 213 . The substrate 205 may be silicon-based: the upper surface 207 may be parallel to the (100) crystal plane. The groove surface 213 may be parallel to the (111) crystal plane. (Alternatively, the upper surface 207 may be parallel to the (111) crystal plane. The trench surface 213 may be parallel to the (100) crystal plane.) The trench 210 may thus have the shape of an inverted pyramid or a truncated inverted pyramid in the substrate 205 shape, thereby forming a square opening in the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com