Preparation method of heteropoly acid catalysts by taking organic modified concave-convex soil as carrier

A technology for modifying attapulgite and attapulgite, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., and can solve the problems of small specific surface area of heteropolyacids, difficulty in recycling easily soluble in polar solvents, etc. , to achieve the effects of improved reusability, stable activity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

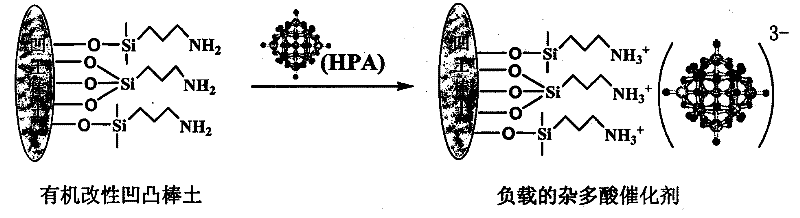

[0017] Preparation of phosphotungstic acid catalyst supported by attapulgite modified with silane coupling agent KH550: Attapulgite modified with KH550 2g, heat and vacuumize for 90min, add phosphotungstic acid containing 0.6g of phosphotungstic acid under vacuum Ethanol-water (1:1, v:v) solution, stirred overnight, filtered, washed with ethanol-water mixture, and the residual solvent was removed under vacuum to obtain a supported phosphotungstic acid catalyst.

[0018] It has been determined that the loading capacity of phosphotungstic acid is 20%, and the specific surface area is 160.3m 2 / g, the pore volume is 0.255cm 3 / g.

Embodiment 2

[0020] Preparation of phosphomolybdic acid catalyst with silane coupling agent KH550 modified attapulgite as carrier: 2 g of KH550 modified attapulgite, heat and vacuumize for 150 min, add 50 mL of ethanol solution containing phosphomolybdic acid, stir overnight, filter , washed with ethanol, and removed the residual solvent under vacuum to obtain a supported phosphomolybdic acid catalyst.

[0021] It has been determined that the loading capacity of phosphomolybdic acid is 25%, and the specific surface area is 146.7m 2 / g, the pore volume is 0.238cm 3 / g.

Embodiment 3

[0023] Preparation of phosphotungstic acid catalyst with attapulgite modified by silane coupling agent SG-Si900 as the carrier: 2g of attapulgite modified by SG-Si900, heat and vacuumize for 90min, add 50mL of cyanogen phosphotungstate solution , stirred overnight, filtered, washed, and removed the residual solvent under vacuum to obtain a loaded phosphotungstic acid catalyst.

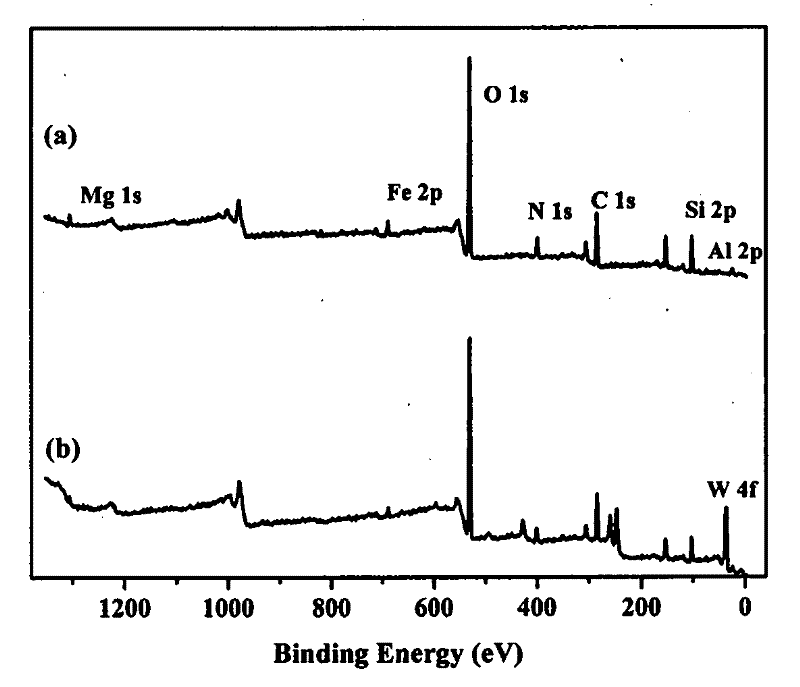

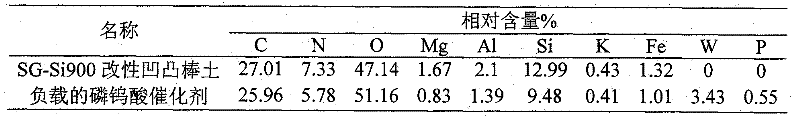

[0024] After determination, the relative contents of some elements in the product are shown in Table 1.

[0025] X-ray energy spectrum (XPS) relative content of table 1 sample

[0026]

[0027] From the XPS relative content of the samples in Table 1, it can be seen that the relative content of O element after modification increases to 51.16%, and the relative content of W and P elements are 3.43% and 0.55%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com