Suspended multi-pipe microporous aerator

A microporous aerator, suspended technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc. The problem of high cost is to avoid sewage backflow, not easy to break, and reduce sludge deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

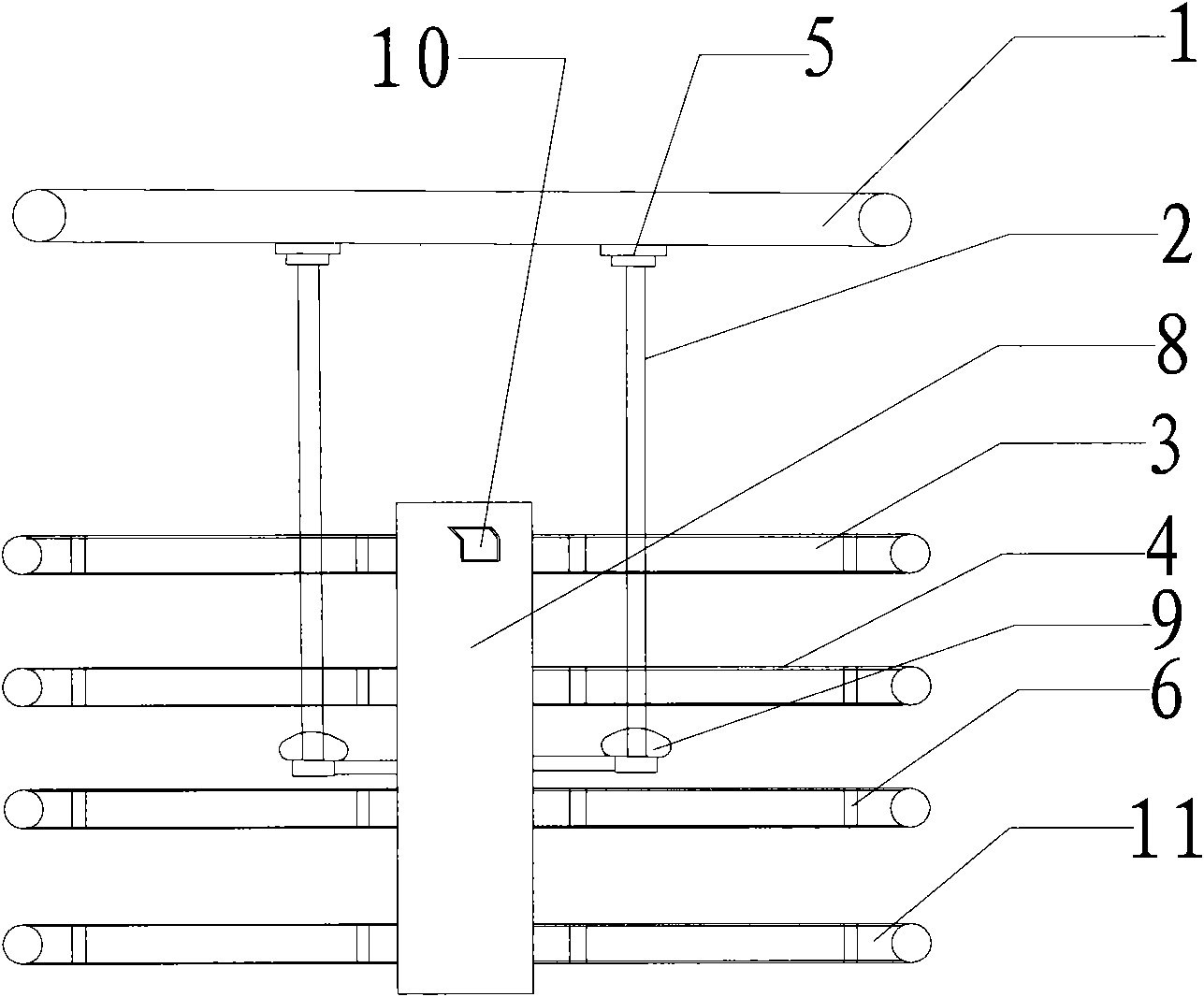

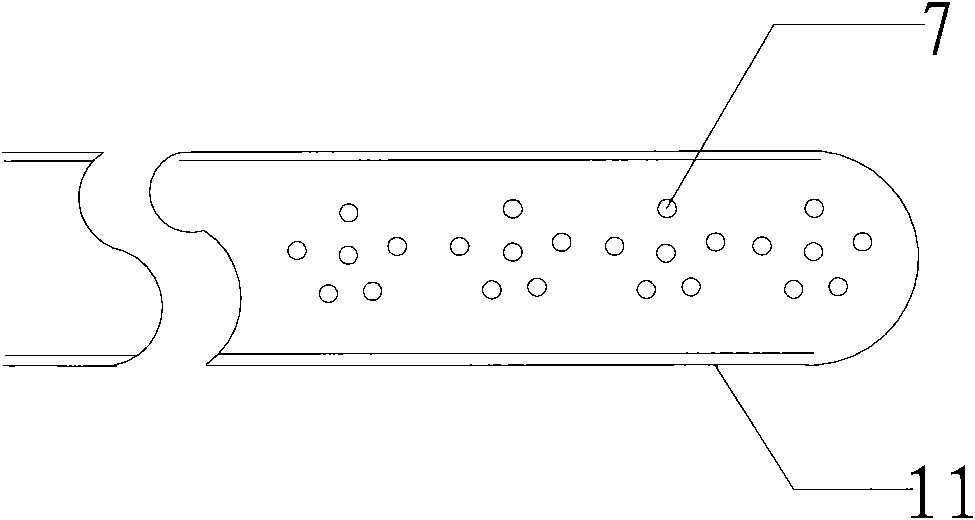

[0020] Such as figure 1 and 2 As shown, the present invention includes an air intake branch pipe 1, an air intake flexible branch pipe 2, a support pipe 3, an air flow distributor 11 and a rubber membrane sleeve 4, and one end of two air intake flexible branch pipes 2 communicates with the air intake branch pipe 1 through a tee 5 , the rubber membrane sleeve 4 is set on the support tube 3, the rubber membrane sleeve 4 is fixed by the clamp 6 at both ends of the support tube 3, and the air flow distributor 11 of the rubber membrane sleeve 4 is provided with a self-closing micropore 7, eight or two supports The left and right sides of the pipe 3 are connected and fixed on the gas circuit communication pipe 8, the other end of the air intake flexible branch pipe 2 is connected to the gas circuit communication pipe 8, and the corners of the two intake flexible branch pipes 2 are respectively sleeved with counterweights 9, and the membrane sleeve is slightly The holes 7 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com