Flame-retardant thermoplastic composition and preparation method thereof

A thermoplastic composition and mixture technology, applied in the field of nylon molding materials, can solve the problems of corrosion of electrical equipment, high phosphorus precipitation, easy corrosion of processing equipment and molds, etc. The effect of good flame retardancy and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preparation method: mix each component in a twin-screw extruder (twin-screw diameter is 75mm, aspect ratio is 38), mix at a temperature of 230-300°C, discharge as strands and cool to a temperature capable of granulation Granulate. After the pellets are dried (usually at 80°C in a vacuum oven for 2 days), the dried pellets are processed at a temperature of 230°C-300°C into standard samples for UL94V tests, and are also made according to GB1040, GB9341 , The standard sample specified in GB1843 is also made into a 50mm×6mm×4mm sample to test phosphorus precipitation.

[0034] A: Nylon resin (FYR27B Shenma Group Co., Ltd.);

[0035] B: red phosphorus flame retardant;

[0036] C: glass fiber (HP3786 32MM, Taiwan Bicheng Co., Ltd.)

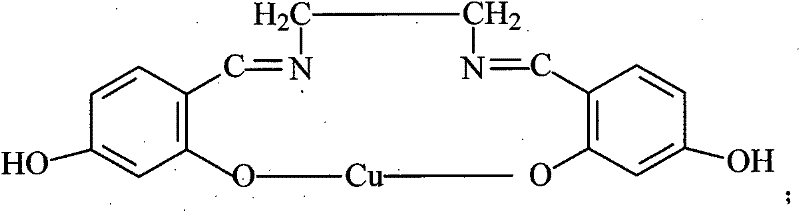

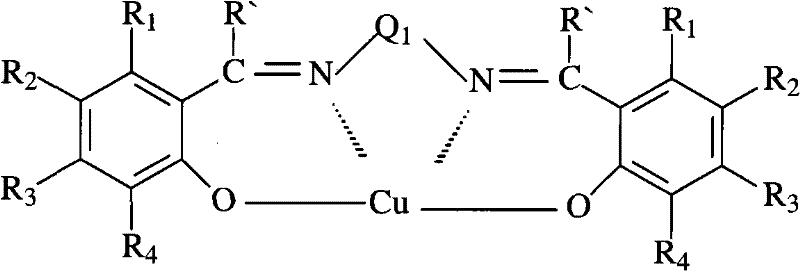

[0037] D: copper compound,

[0038] D1: Aldrich

[0039] D2: CuCl, Aldrich

[0040] E. Other additives

[0041] Example

[0042] The results given in the table clearly show that due to the addition of the copper compound accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com