Pavement base course material prepared from brick mixed building rubbish regenerated aggregate and preparation method thereof

A technology for recycling aggregates and construction waste, which is applied in buildings, roads, roads and other directions to achieve the effects of large material selectivity, extended service life and low wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

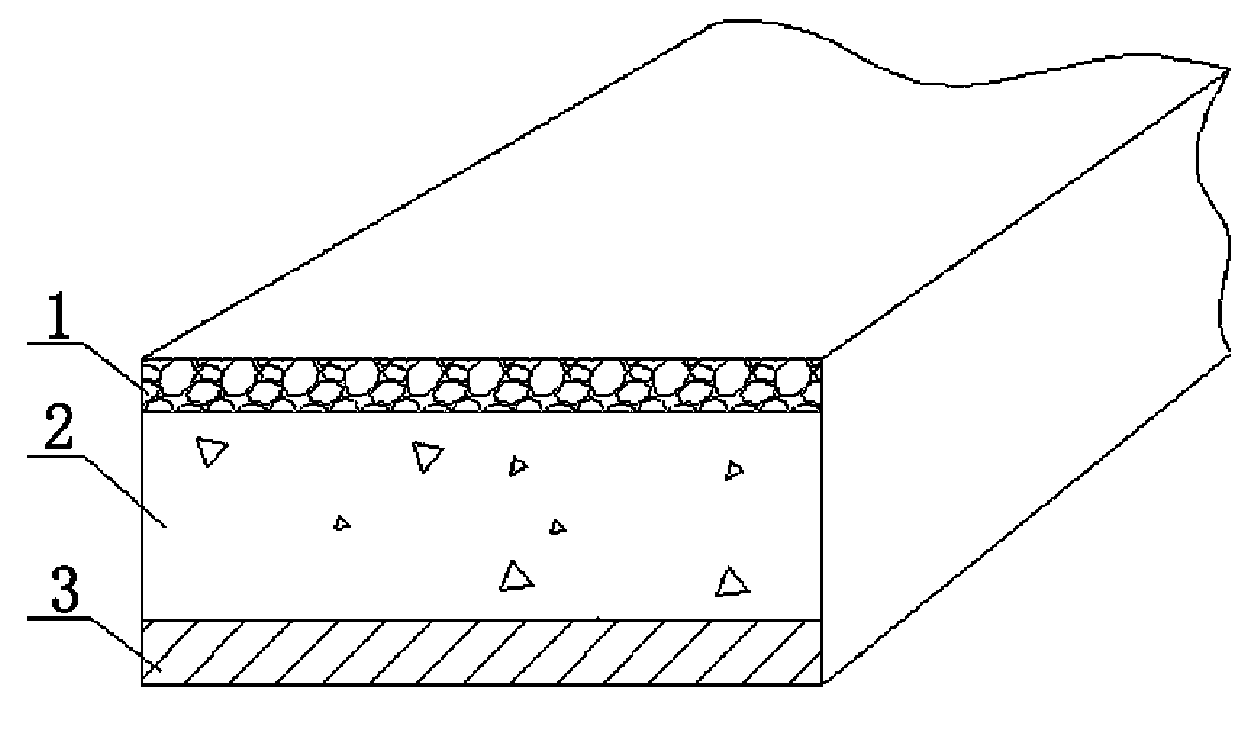

[0036] Embodiment one sees figure 1 Shown: This kind of subgrade built by using recycled aggregates of brick-concrete construction waste has a 180-800 mm thick regenerated inorganic binder stabilized material layer on the lower bearing layer 3, and a regenerated inorganic binder stabilized material layer is built on the regenerated inorganic binder stabilized material layer. Road surface layer 1, the road surface layer is a concrete surface layer, an asphalt mixture surface layer, or a road surface layer composed of oil-permeable, gravel, and intermediate layers. The recycled inorganic binder stabilized material layer is a recycled inorganic binder stabilized material layer 2 made of brick-concrete construction waste recycled aggregate particles mixed with ordinary aggregates and alkaline gelling powder, and the recycled inorganic binder stabilized material layer 2 It is a single structural layer laid by one material, and the material can be one of the following three ratios: ...

Embodiment 2

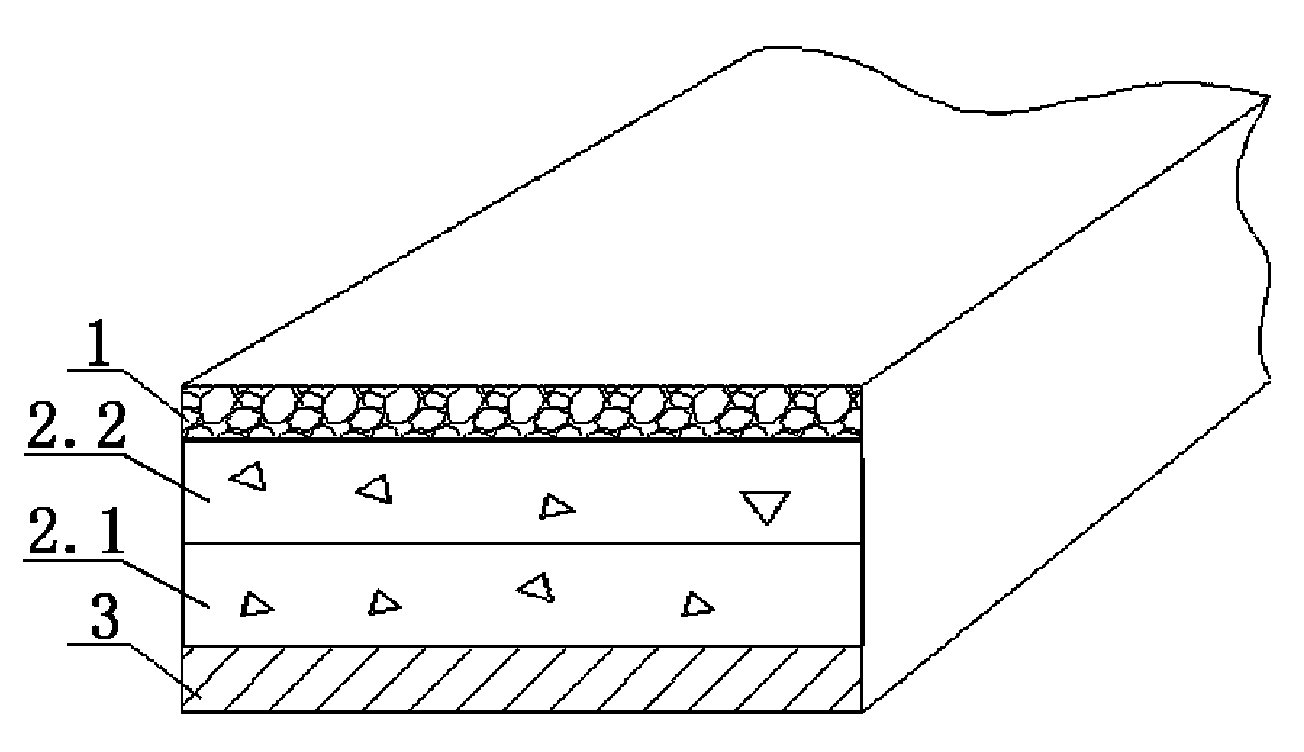

[0045] Embodiment two, see figure 2 As shown, the recycled inorganic binder stabilizing material layer 2 is divided into two layers: the lower layer 2.1 of the recycled inorganic binder stabilizing material and the upper layer 2.2 of the recycled inorganic binder stabilizing material. The thickness of each layer of the lower layer 2.1 of the recycled inorganic binder stabilized material and the upper layer 2.2 of the recycled inorganic binder stabilized material is preferably 180-200mm, the minimum compacted thickness is not less than 150mm, and the acceptance deflection value of the recycled inorganic binder stabilized material layer is generally less than 30 (0.01mm). The lower layer 2.1 of recycled inorganic binder stabilized material can be laid with brick-mixed recycled inorganic binder stabilized coarse aggregate, and the upper layer 2.2 of recycled inorganic binder stabilized material can be laid with brick-mixed recycled inorganic binder stabilized medium aggregate. ...

Embodiment 3

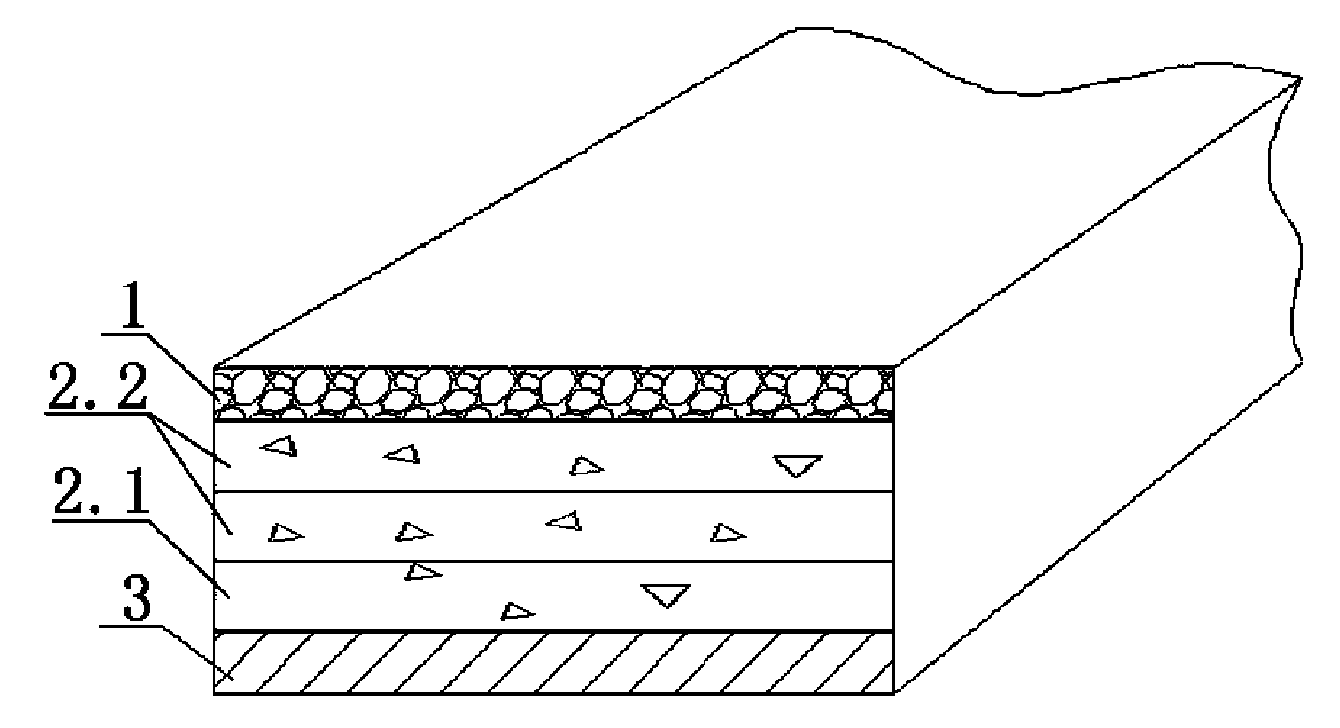

[0048] Embodiment three, see image 3 As shown, the recycled inorganic binder stabilized material layer 2 is divided into two parts: the lower layer 2.1 of the recycled inorganic binder stabilized material and the upper layer 2.2 of the recycled inorganic binder stabilized material. The lower layer 2.1 of the recycled inorganic binder stabilized material has a layer, and the recycled inorganic binder stabilized material Material The upper layer 2.2 consists of two layers. The thickness of each layer is preferably 180-200mm, the minimum compacted thickness is not less than 150mm, and the acceptance deflection value of the recycled inorganic binder stabilized material layer is generally not less than 25 (0.01mm). The lower layer 2.1 of the recycled inorganic binder stabilized material can be paved with brick-mixed recycled coarse inorganic binder stabilized material, and the two layers of the upper layer 2.2 of the recycled inorganic binder stabilized material can use brick-mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com