Fiber grating Fabry-Perot cavity vibration sensor and vibration measurement system thereof

A vibration sensor, fiber grating technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of insufficient detection capability of weak vibration signals, expensive wavelength demodulation equipment, and inability to measure vibration information. Simple structure, improved precision and good electromagnetic insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

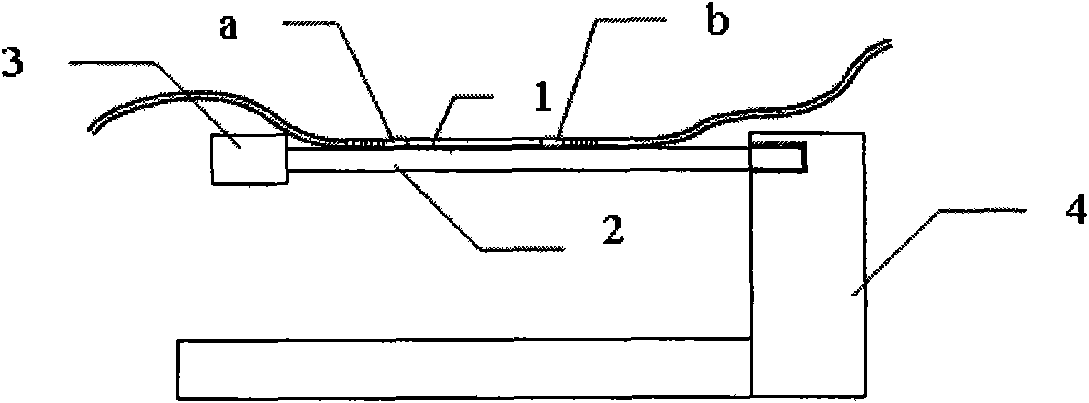

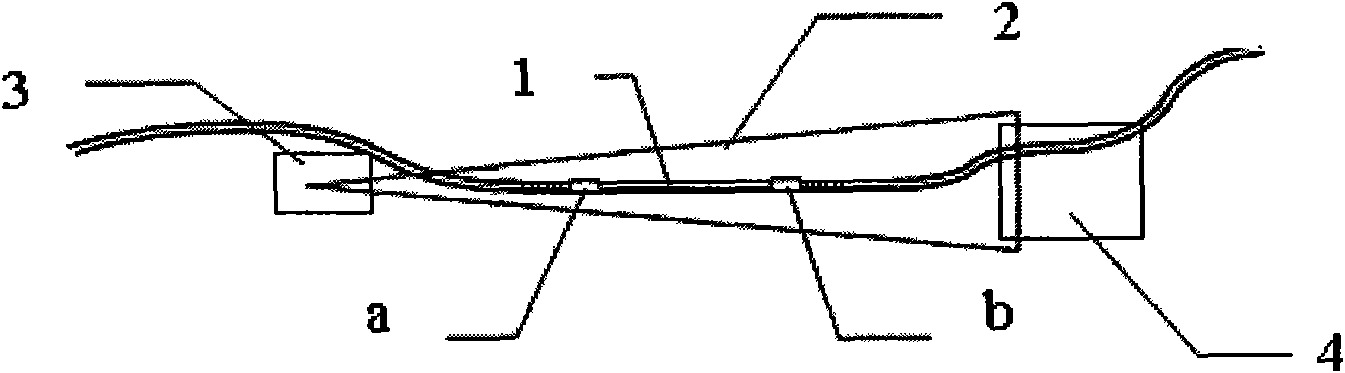

[0020] The fiber grating F-P cavity vibration sensor of the embodiment of the present invention refers to the attached figure 1 And attached figure 2 .

[0021] Paste the two ends of the fiber grating F-P cavity 1 on the middle position of the equal-strength cantilever beam 2 , one end of the cantilever beam 2 is fixed on the support 4 , and a mass block 3 is fixed at the other end. Wherein the reflectivity of the fiber grating F-P cavity is less than 5%. The cantilever beam adopts an isosceles triangular elastic steel plate with a length of 60mm, a width of 25mm at one end fixed to the bracket, and a thickness of 2mm. The quality block is an aluminum block with a size of 5×5×5mm.

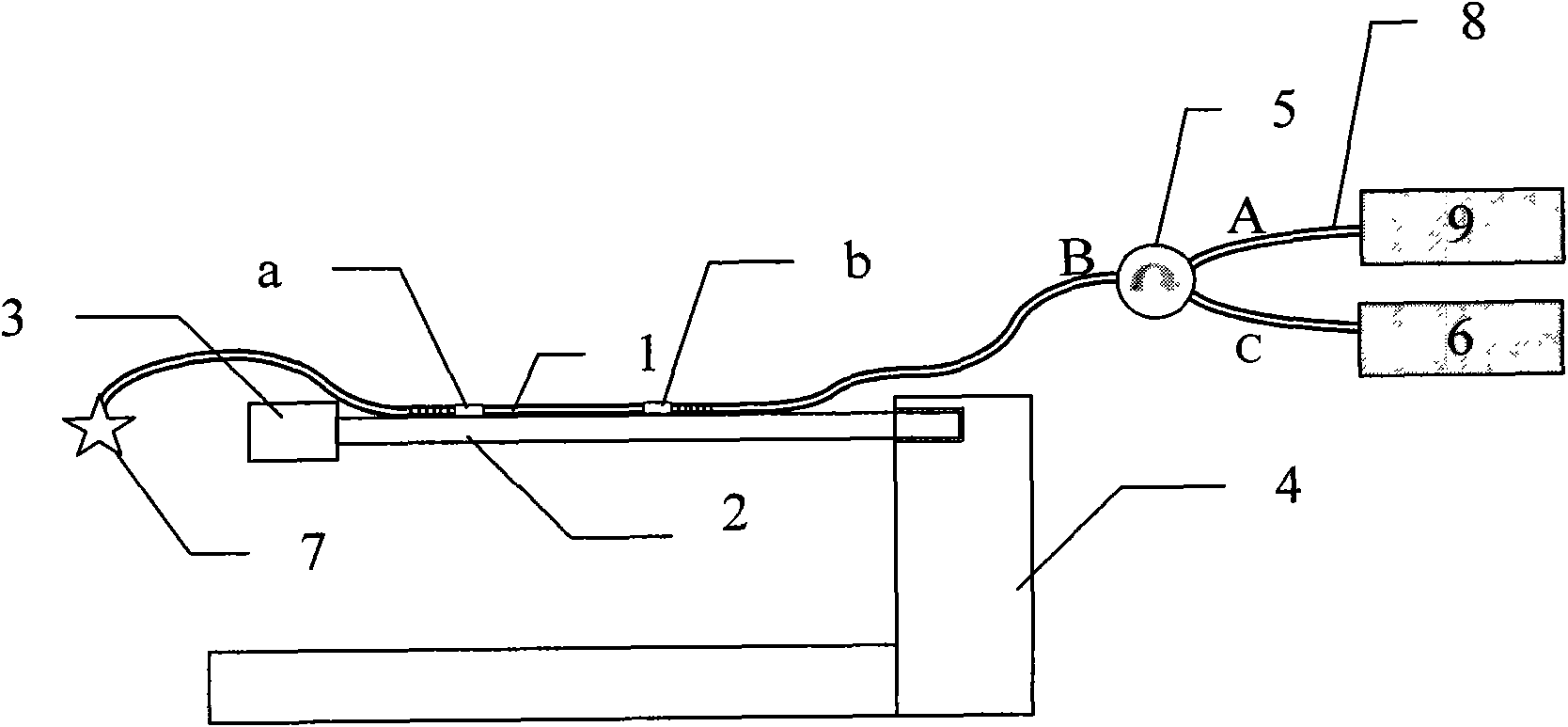

[0022] The measuring system of the embodiment of the present invention sees attached image 3 .

[0023] The end of the optical fiber in the fiber grating F-P cavity vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com