Laser device with long depth of focus

A technology of laser device and depth of focus, which is applied in the direction of exposure device, optics, optical components, etc. of photoengraving process, can solve the problems of reducing light utilization efficiency and increasing cost, and achieves a simple structure, low manufacturing cost and high light utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

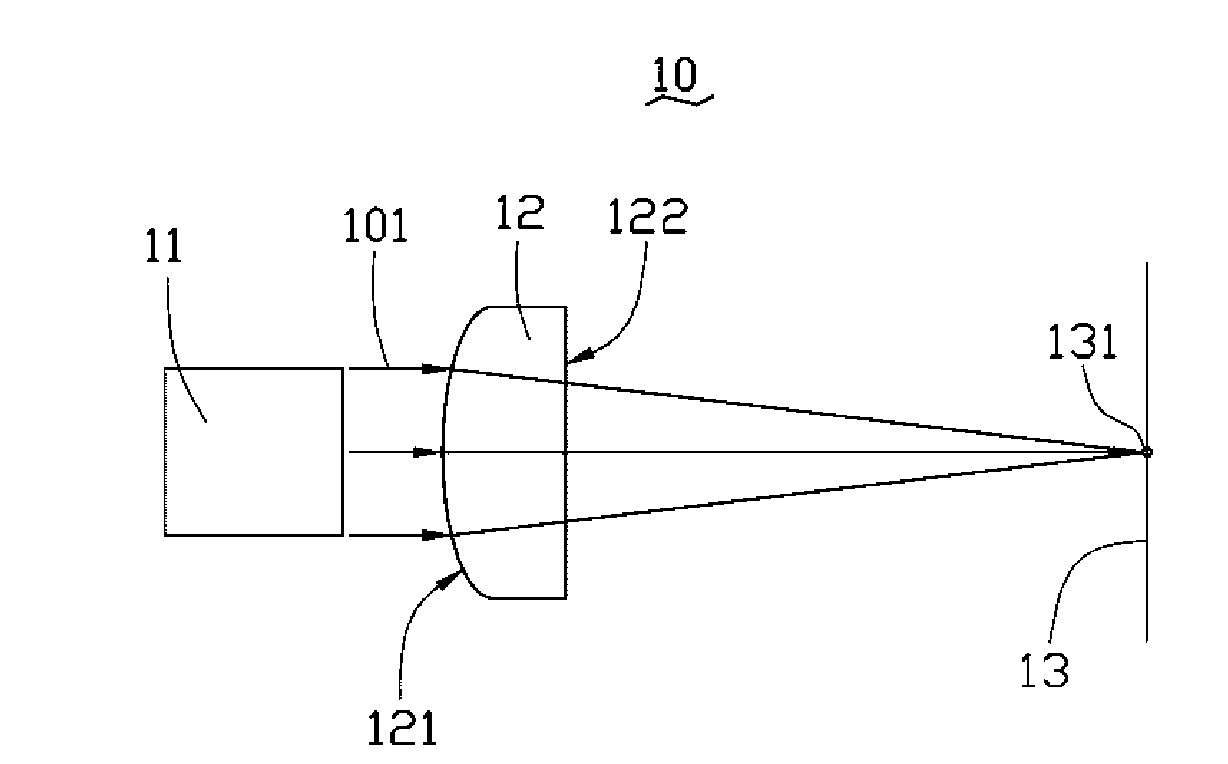

[0013] See figure 1 , the laser device 10 provided by the first embodiment of the present invention includes a laser source 11 and an optical module 12 .

[0014] The laser source 11 is used to emit single-wavelength ultraviolet light 101 .

[0015] The optical module 12 is a lens, which is arranged on the optical path of the single-wavelength ultraviolet light 101 . The optical module 12 has a first surface 121 adjacent to the laser source 11 , and a second surface 122 opposite to the first surface 121 . The first surface 121 is an aspherical surface defined by a conic constant or aspheric coefficients. The second surface 122 is a plane. The single-wavelength ultraviolet light 101 emitted by the laser source 11 is transmitted through the first surface 121 of the optical module 12 and then converged onto the image plane 13 to form a light spot 131 .

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com