Coloring light-sensitive resin composition

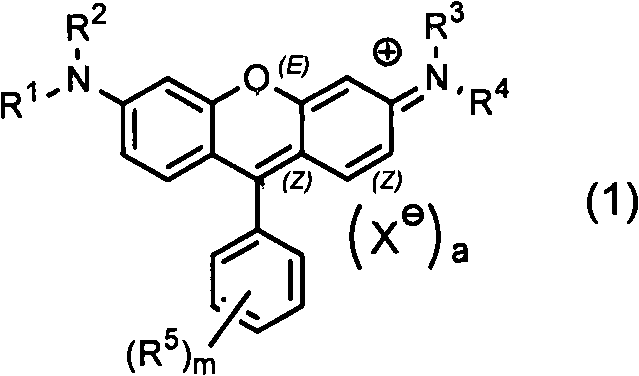

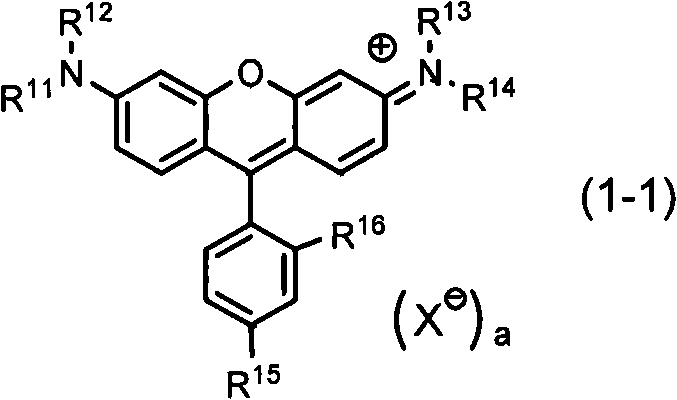

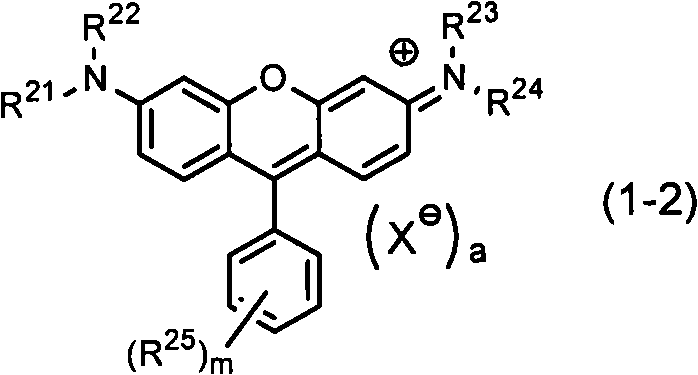

A photosensitive resin and composition technology, applied in optics, filters, optical components, etc., can solve problems such as low contrast of color filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0203] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples. "%" and "part" in an example are % by weight and a part by weight, unless otherwise indicated.

Synthetic example 1

[0205] 15 parts of sulforhodamine (Sulhorodamine) B (manufactured by Kanto Chemical Co., Ltd.), 150 parts of chloroform and 9.8 parts of N, N-dimethylformamide were dropped into a flask with a cooling tube and a stirring device, and maintained under stirring. Below 20°C, 12.0 parts of thionyl chloride was added dropwise. After completion of the dropping, the temperature was raised to 50°C, and the temperature was maintained for 5 hours to react, and then cooled to 20°C. While maintaining the cooled reaction solution at 20° C. or lower with stirring, a mixed solution of 13.9 parts of 2-ethylhexylamine and 24.5 parts of triethylamine was added dropwise. Then, stirring was carried out at the same temperature for 5 hours to make it react. Next, after distilling off the solvent in the obtained reaction mixture with a rotary evaporator, a small amount of methanol was added and vigorously stirred. This mixture was added to a mixed solution of 375 parts of ion-exchanged water while ...

Synthetic example 2

[0208] In the flask with cooling tube and stirring device, drop into 15 parts of pigments shown in formula A0-2 (manufactured by Zhongwai Huacheng), 150 parts of chloroform and 7.1 parts of N, N-dimethylformamide, while maintaining at 20 Below ℃, 8.7 parts of thionyl chloride were added dropwise. After completion of the dropping, the temperature was raised to 50°C, and the temperature was maintained for 5 hours to react, and then cooled to 20°C. A mixed solution of 10 parts of 2-ethylhexylamine and 17.7 parts of triethylamine was added dropwise while maintaining the cooled reaction solution at 20° C. or lower with stirring. Then, stirring was carried out at the same temperature for 5 hours to make it react. Next, after distilling off the solvent in the obtained reaction mixture with a rotary evaporator, a small amount of methanol was added and vigorously stirred. This mixture was added to a mixed solution of 375 parts of ion-exchanged water while stirring to precipitate crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com