Method and apparatus for estimating exhaust temperature of an internal combustion engine

A technology of exhaust temperature and internal combustion engine, applied in mechanical equipment, internal combustion piston engine, combustion engine, etc., can solve problems such as increased system complexity, large amount of computing resources, and difficult empirical model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

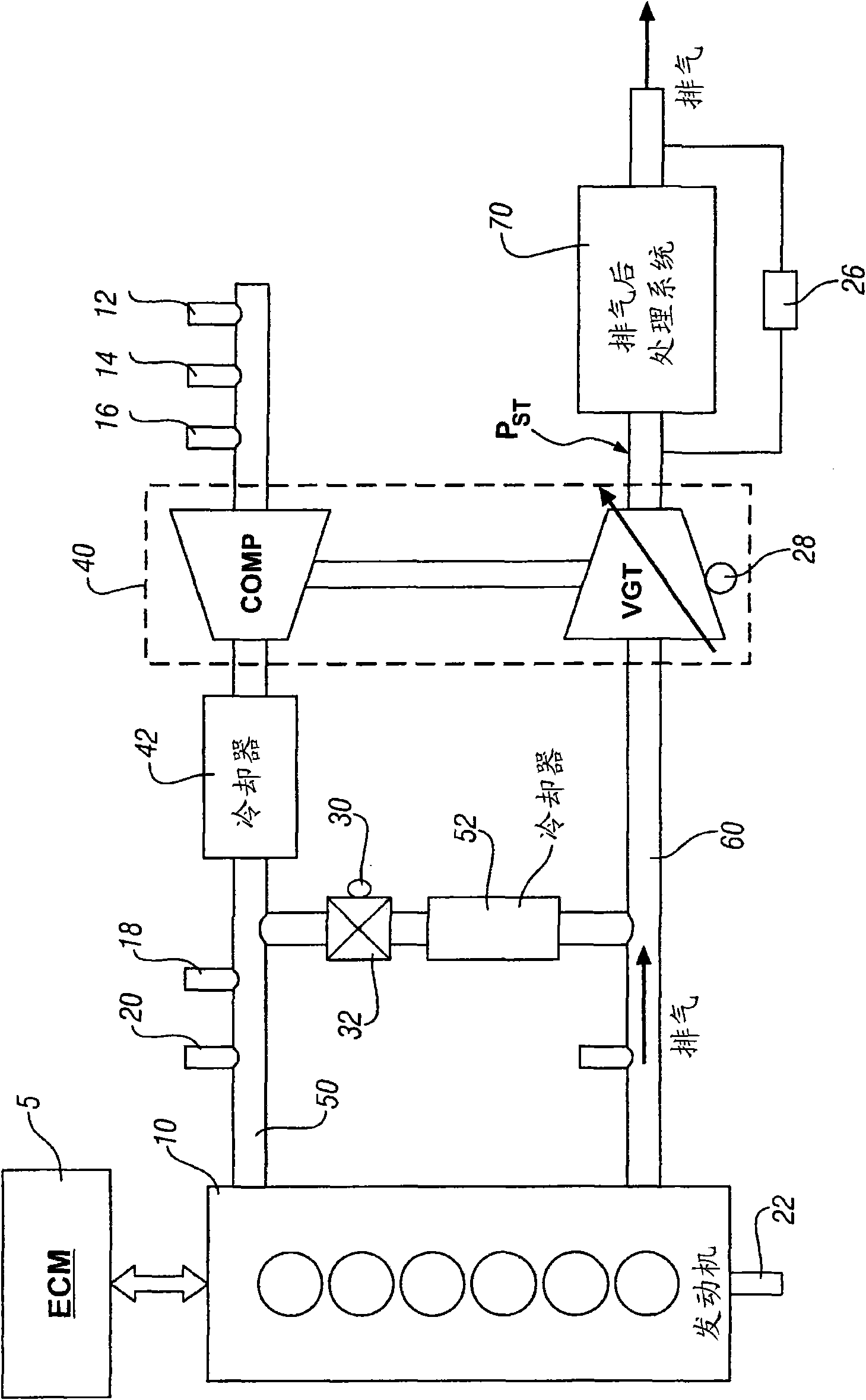

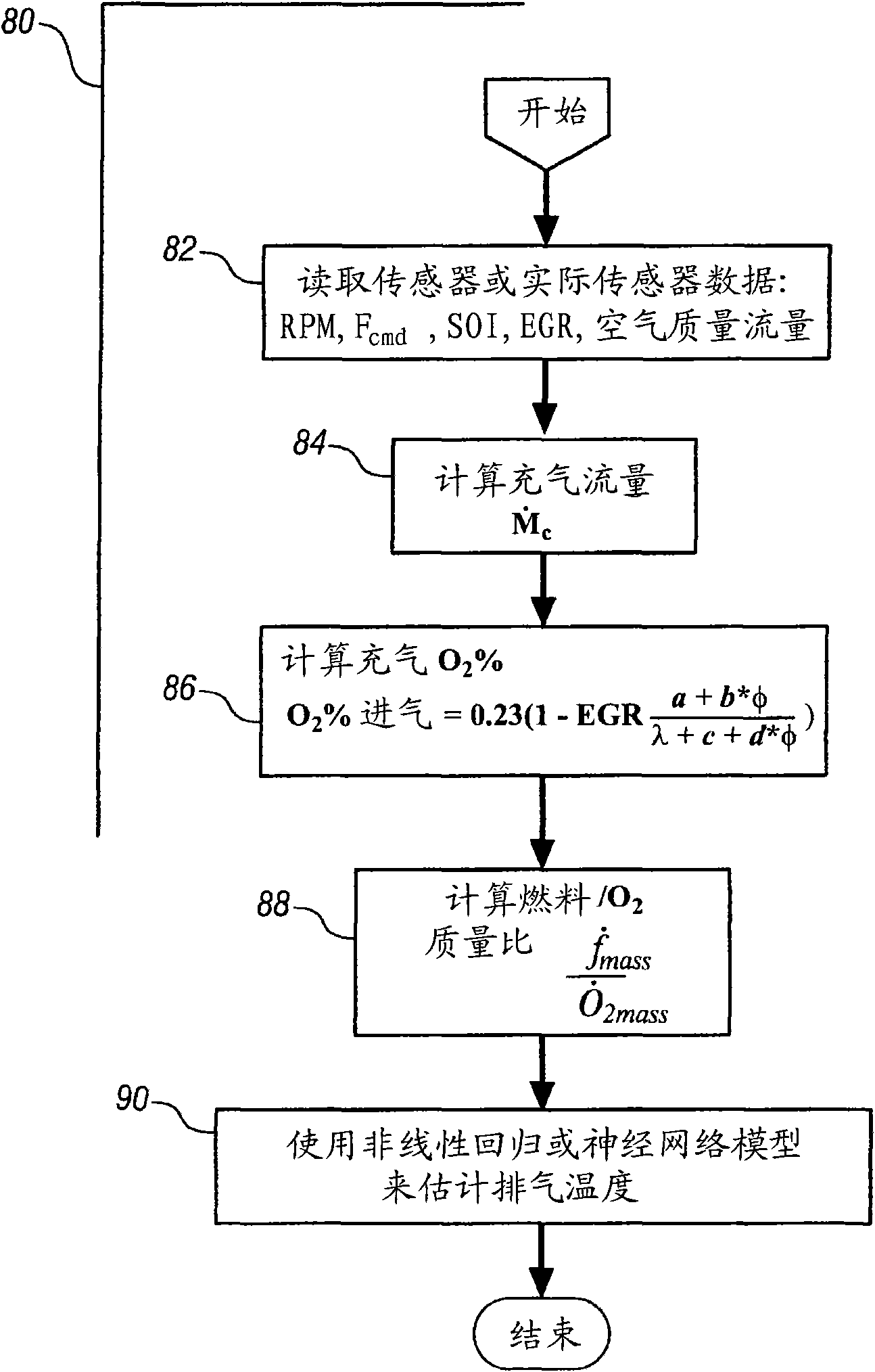

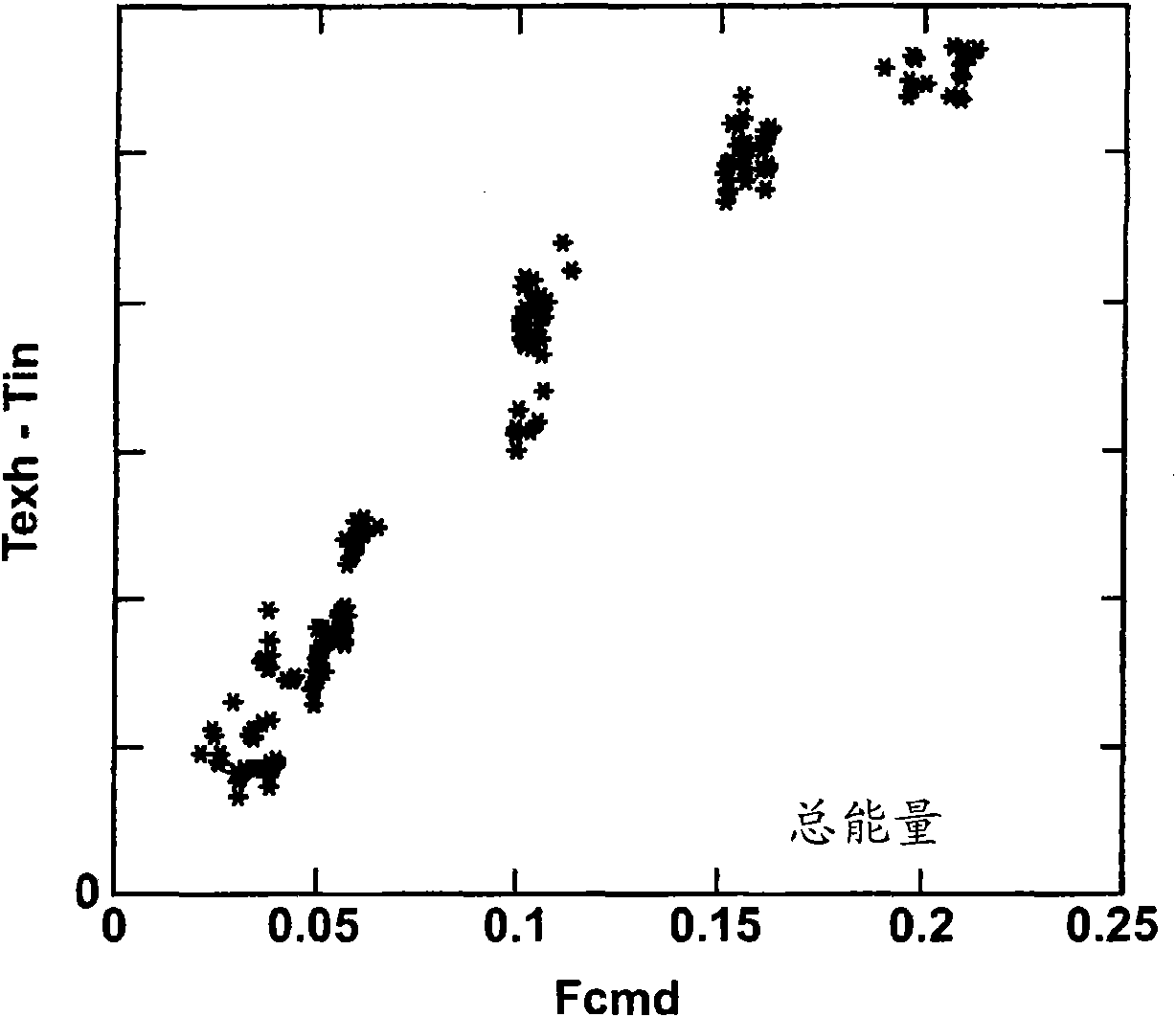

[0020] Referring now to the drawings, wherein the illustrations are only for illustrating the present invention and are not intended to limit the present invention. figure 1 An engine 10 and an engine control module (ECM) 5 constructed in accordance with an embodiment of the present invention are depicted. Exemplary engine 10 includes a multi-cylinder internal combustion engine mechanically designed to operate in a compression ignition configuration, although the present invention is not necessarily limited to compression ignition engine configurations. A variable displacement combustion chamber is formed in the cylinder between the engine cover and the reciprocating piston attached to the crankshaft. Engine system components include intake compressor 40 including variable geometry turbine (VGT) and air compressor (COMP), charge air cooler 42, exhaust gas recirculation (EGR) valve 32 and cooler 52, intake manifold 50. Exhaust manifold and downflow pipe 60 and exhaust aftertre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com