Cold-side adjustment method for temperature and pressure of high temperature flue gas system of heat recovery coke oven

A technology of high-temperature flue gas and system temperature, which is applied in the field of pressure regulation and heat recovery of coke oven high-temperature flue gas temperature, can solve the problem of large coke burning loss, and achieve the effects of reducing labor intensity, convenient adjustment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

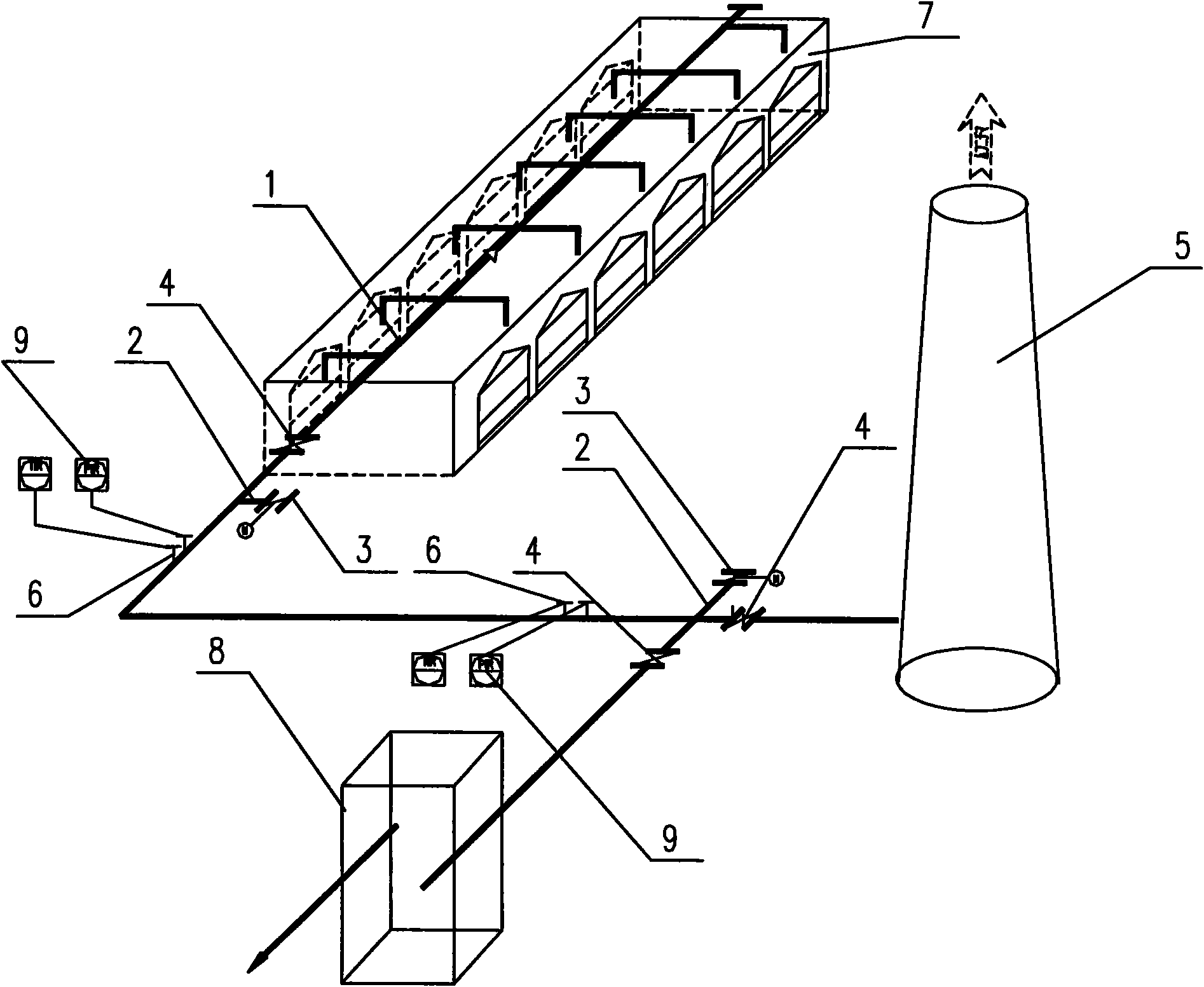

[0018] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0019] see figure 1 , A method for adjusting the temperature and pressure of the cold end of the heat recovery coke oven high temperature flue gas system. The method uses a plurality of air suction ports 2 communicating with the atmosphere on the heat recovery coke oven high temperature flue gas pipeline 1 operated under negative pressure. Inhale air to control the temperature and pressure of the high-temperature flue gas system. Each air intake port 2 is provided with an opening degree adjusting device 3, and the amount of air sucked in is controlled by controlling the opening degree of the adjusting valve. The opening adjustment device can be a manual or electric flap, a manual or electric shutter or other adjustment devices.

[0020] An air suction port 2 is provided on the flue gas pipeline between the flue gas outlet of the coke oven body 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com