Salt-melting furnace for producer gas

A molten salt furnace and molten salt technology, used in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of fuel waste, low combustion efficiency, environmental pollution, etc., and achieve the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

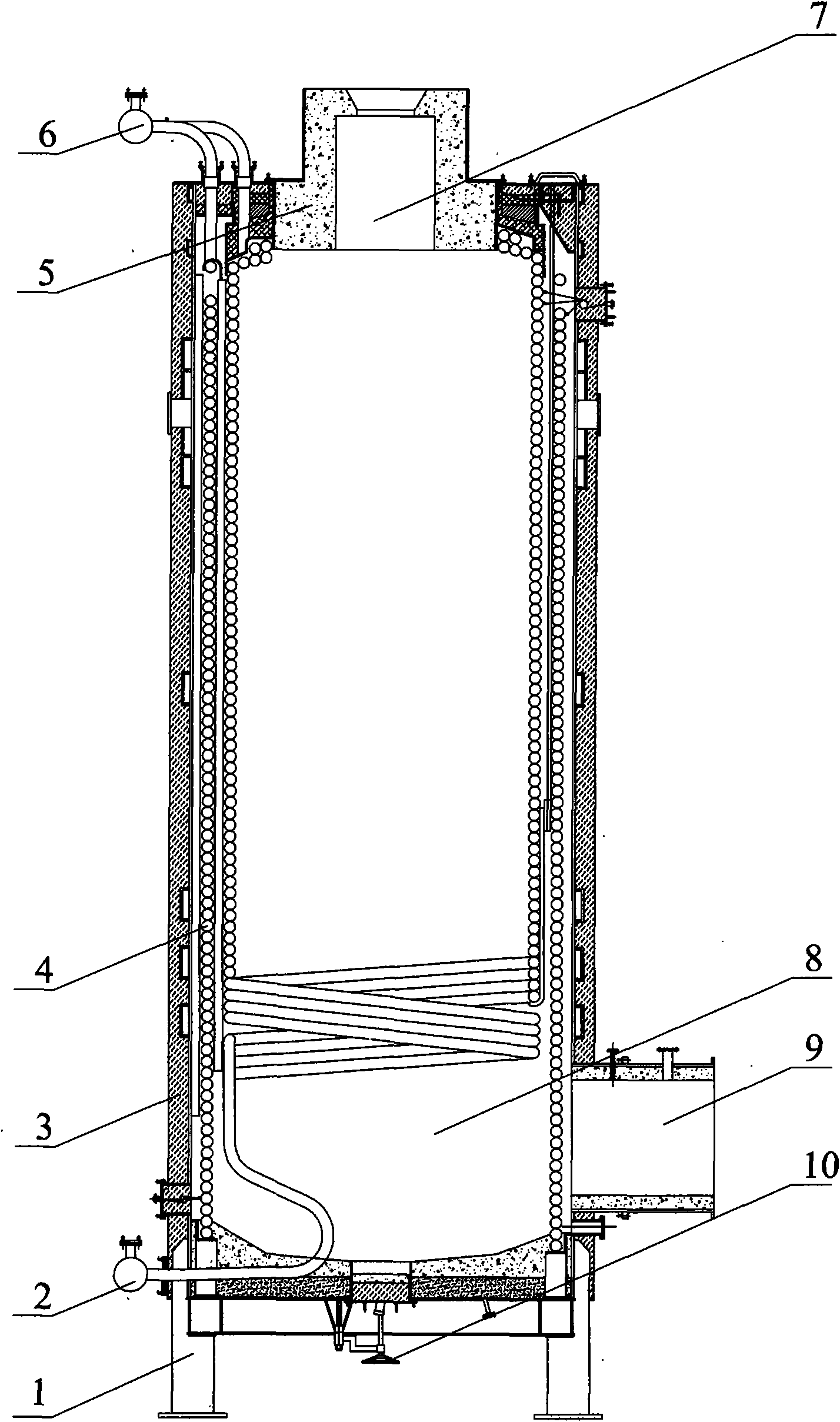

[0009] The present invention is composed of a base 1 of a molten salt furnace, a molten salt furnace body 3 made of high-temperature-resistant iron plates, and a molten salt furnace top plate 5 made of thickened refractory materials. The fuel inlet 9 leading to the fuel and the molten salt heating coil outlet 2 for outputting the heated high-temperature mixed inorganic salt are opened, and the molten salt furnace heating for inputting the mixed inorganic salt in molten state is opened on the upper part of the molten salt furnace body 3 The coil inlet 6 is provided with a flue gas outlet 7 in the middle of the roof 5 of the molten salt furnace for discharging the flue gas generated during fuel combustion, and the inlet 6 of the molten salt heating coil and the outlet 2 of the molten salt heating coil can be used The high temperature resistant molten salt heating coil 4 communicates.

[0010] When the present invention is realized, the mixture of three kinds of powdered inorgani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com