Adjustable triangular conjugated amplitude mould plate and method for realizing apodizing of optical fiber grating

A fiber grating and triangular technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problems of relatively high moving precision, difficult realization, and high cost of ultraviolet reflectors, and achieve flexible writing, simple and easy manufacturing process Realize and solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Descriptions of structural embodiments and methods of the invention are disclosed herein. It is to be understood that the intention is not to limit the invention to the particular disclosed embodiments, but that the invention can be practiced using other features, elements, methods and embodiments. Similar elements in different embodiments are generally labeled with similar numbers.

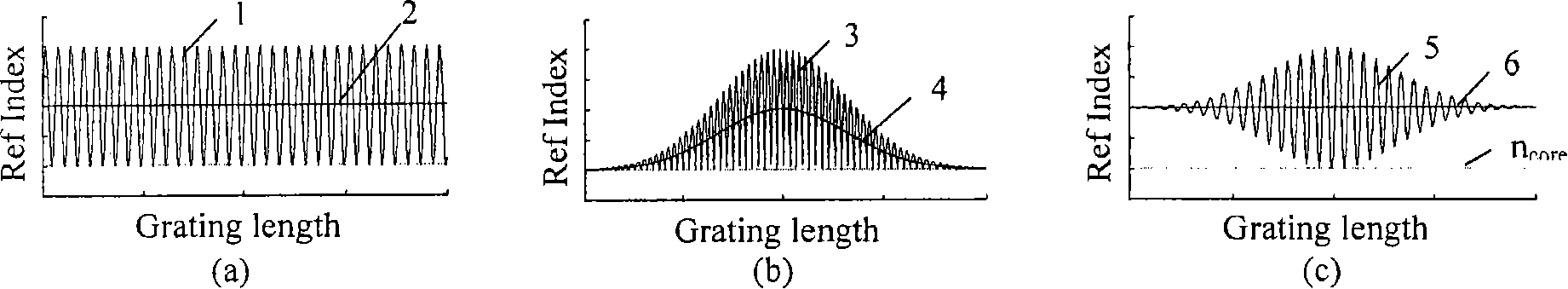

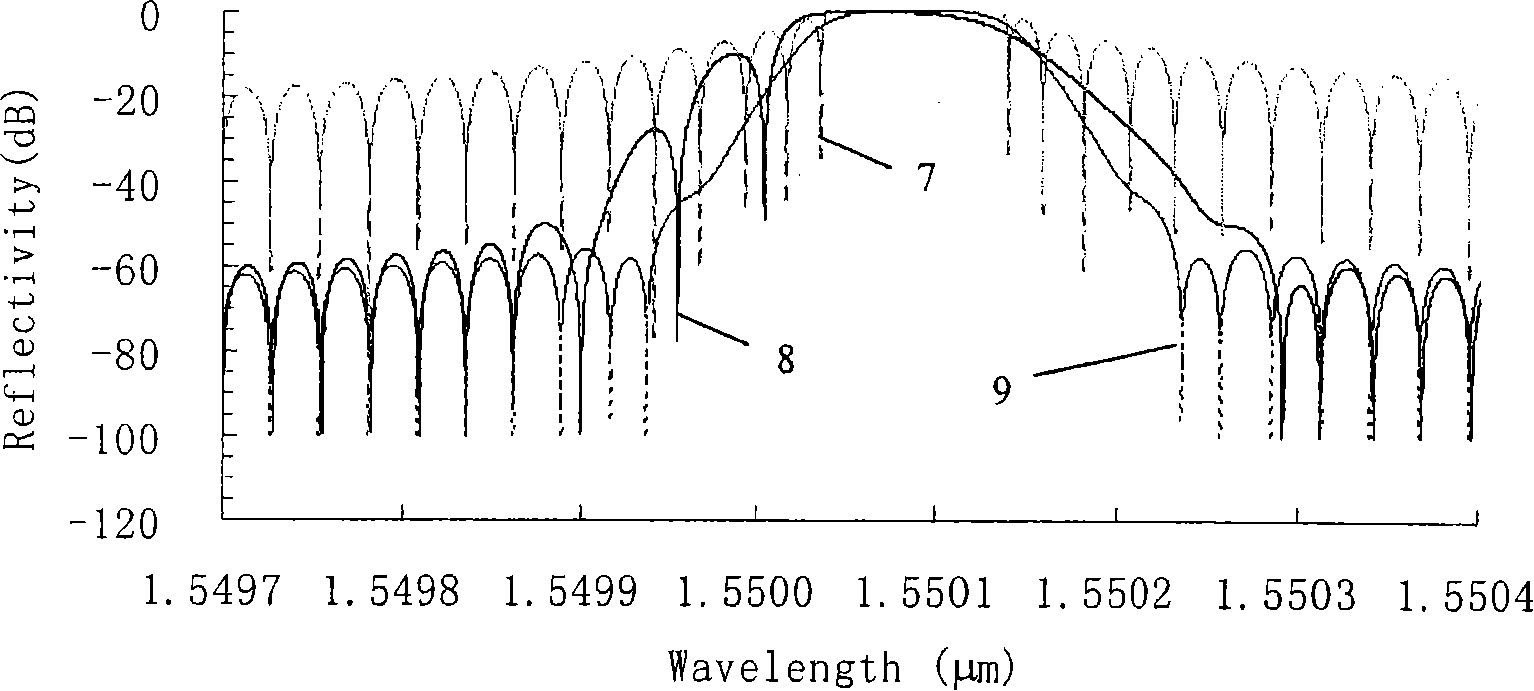

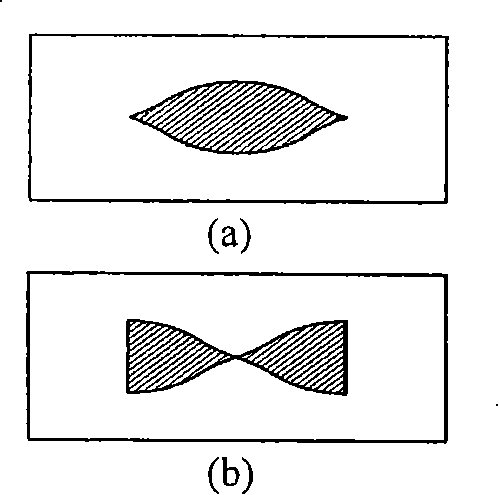

[0048] The apodization of the fiber grating in the present invention is realized based on the apodization scanning of the adjustable triangular conjugate amplitude template 34 . The adjustable triangular conjugate amplitude template 34 mainly includes a conjugate amplitude plate 19, an upper baffle plate 20, a lower baffle plate 21 and a grid length positioning plate (left grid length positioning plate 22, right grid length positioning plate 23). Wherein, the conjugate amplitude plate 19 is composed of two parts, the tangential apodization diaphragm 17 and the inverse apodization diaphrag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com