Binding manufacture technology for electrical element of flat-panel display

A technology of flat panel display and electrical components, applied in the field of binding production technology of flat panel display electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now set forth the present invention in detail in conjunction with accompanying drawing:

[0011] The present embodiment is to bind IC on the flat panel display substrate, and its process steps are: 1) make lead wire on the flat panel display substrate, carry out glass cutting process to lead wire; 2) clean lead wire; 3) coat protective film material on lead wire and pre-curing; 4) exposure treatment of the protective film; 5) development and main curing of the protective film to form the pattern required for the protective film; 6) paving the opposite sex conductive film and IC; 7) thermocompression bonding of the electrical components .

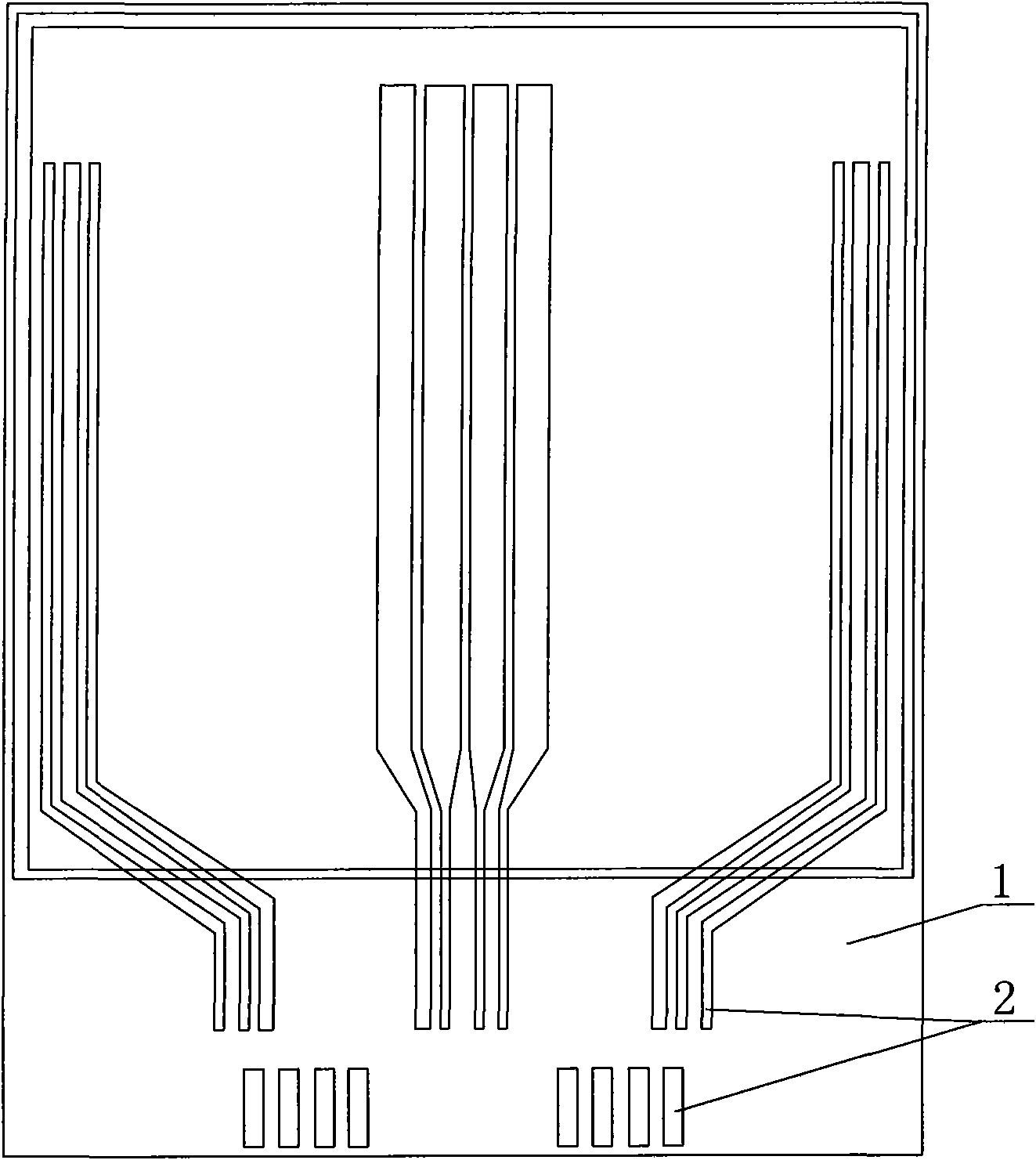

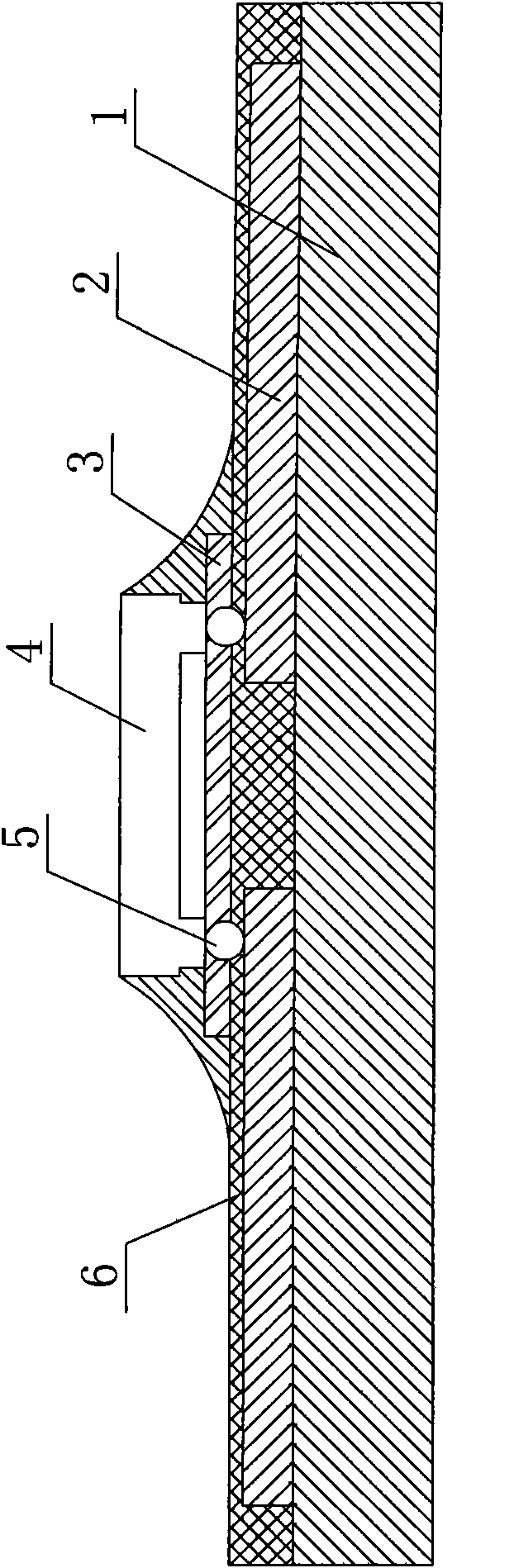

[0012] figure 1 with figure 2 Among them, 1 is the substrate, 2 is the lead wire, 3 is the anisotropic conductive film, 4 is the IC, 5 is the conductive ball, and 6 is the protective film.

[0013] The protective film material is thermoplastic resin or thermoplastic polymer containing polyamide. The characteristics of these two ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com