Method and system for manufacturing battery cathode

A technology of battery negative electrode and driving motor, which is applied in electrode manufacturing, alkaline battery electrode and other directions, can solve the problems of hindering the direct conductive contact between the base material and the metal outer cylinder, waste of hydrogen storage alloy slurry, and reduction of battery yield, etc. The effect of thickness reduction, assembly ratio reduction, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

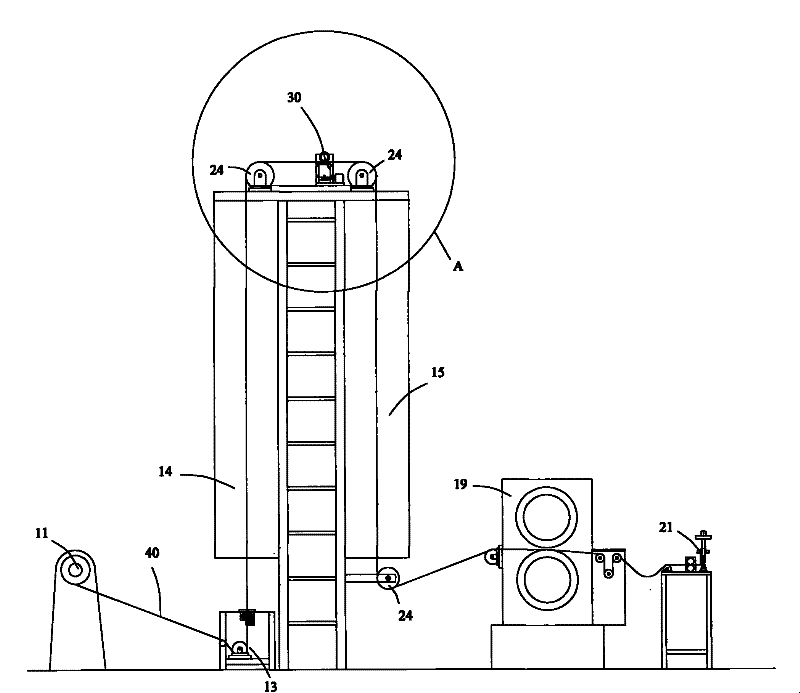

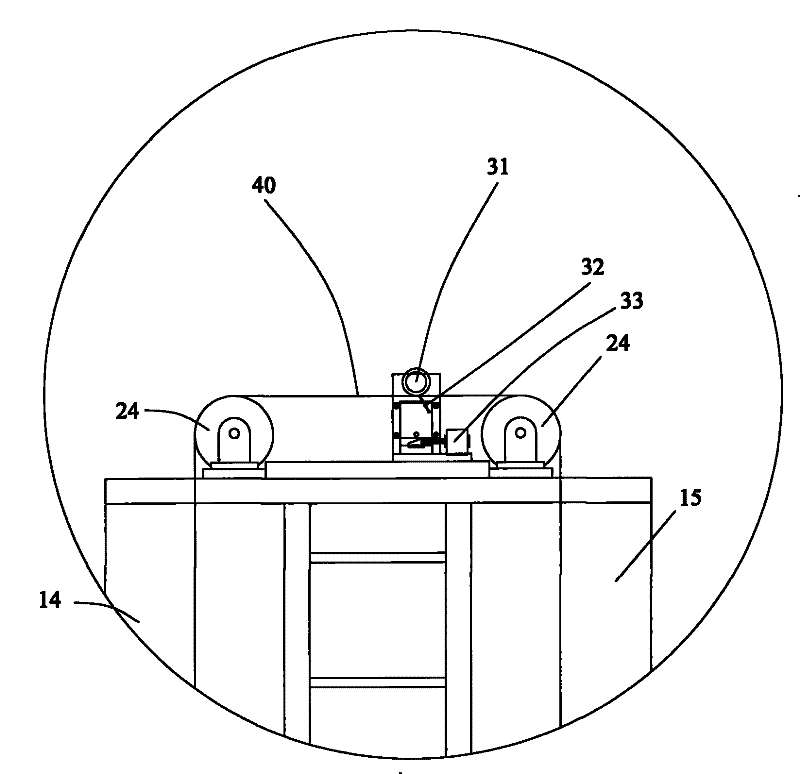

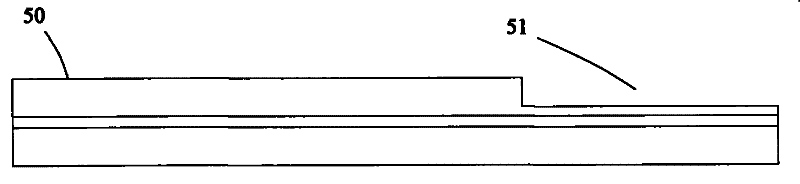

[0018] Such as figure 1 , figure 2 Shown is a specific embodiment of the battery negative electrode production system of the present invention, which includes a continuous arrangement of a discharge device 11, a drying device and a cutting device 21, and a plurality of turning rollers 24 and the like.

[0019] In the method for making the negative electrode of the battery in this embodiment, first, the substrate 40 is installed on the discharge device 11, and the substrate 40 is continuously released by the discharge device 11. The substrate 40 is a nickel-plated perforated substrate or a steel strip, steel net, copper net, cable-stayed net, pure nickel strip and other materials; The viscous hydrogen storage alloy slurry mixed with water is adhered to both sides of the substrate 40 through the sizing device 13 ; and then sent to the drying device.

[0020] In this embodiment, the drying device is a two-stage drying device, including a first baking oven 14 and a second bakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com