Numerical control rocker arm drilling machine

A technology on a radial drilling machine and a radial arm, which is applied to the components of the boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of limited table size, large driving force, waste of energy, etc. Achieve the effect of accurate and reliable positioning, high degree of automation and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

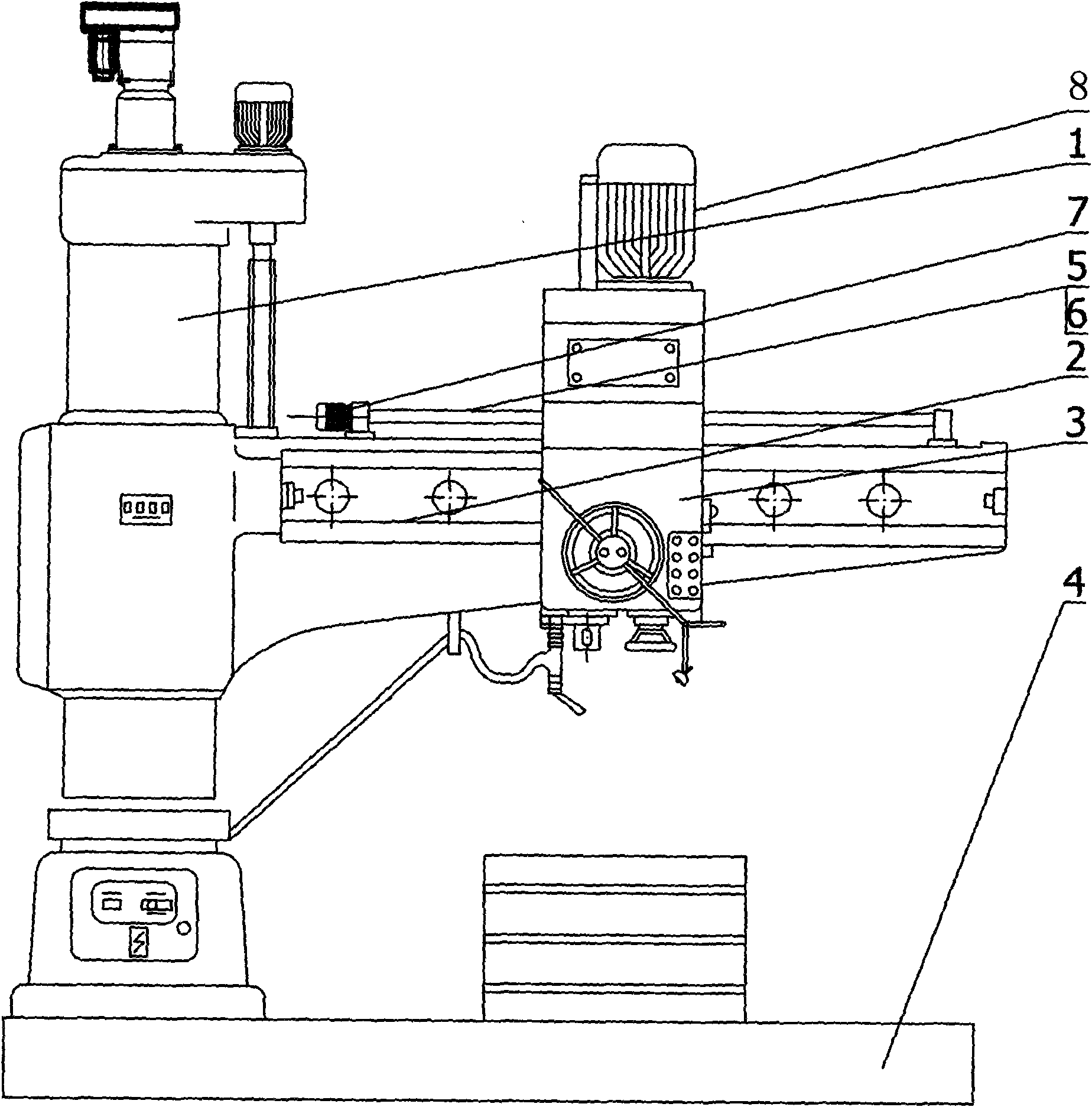

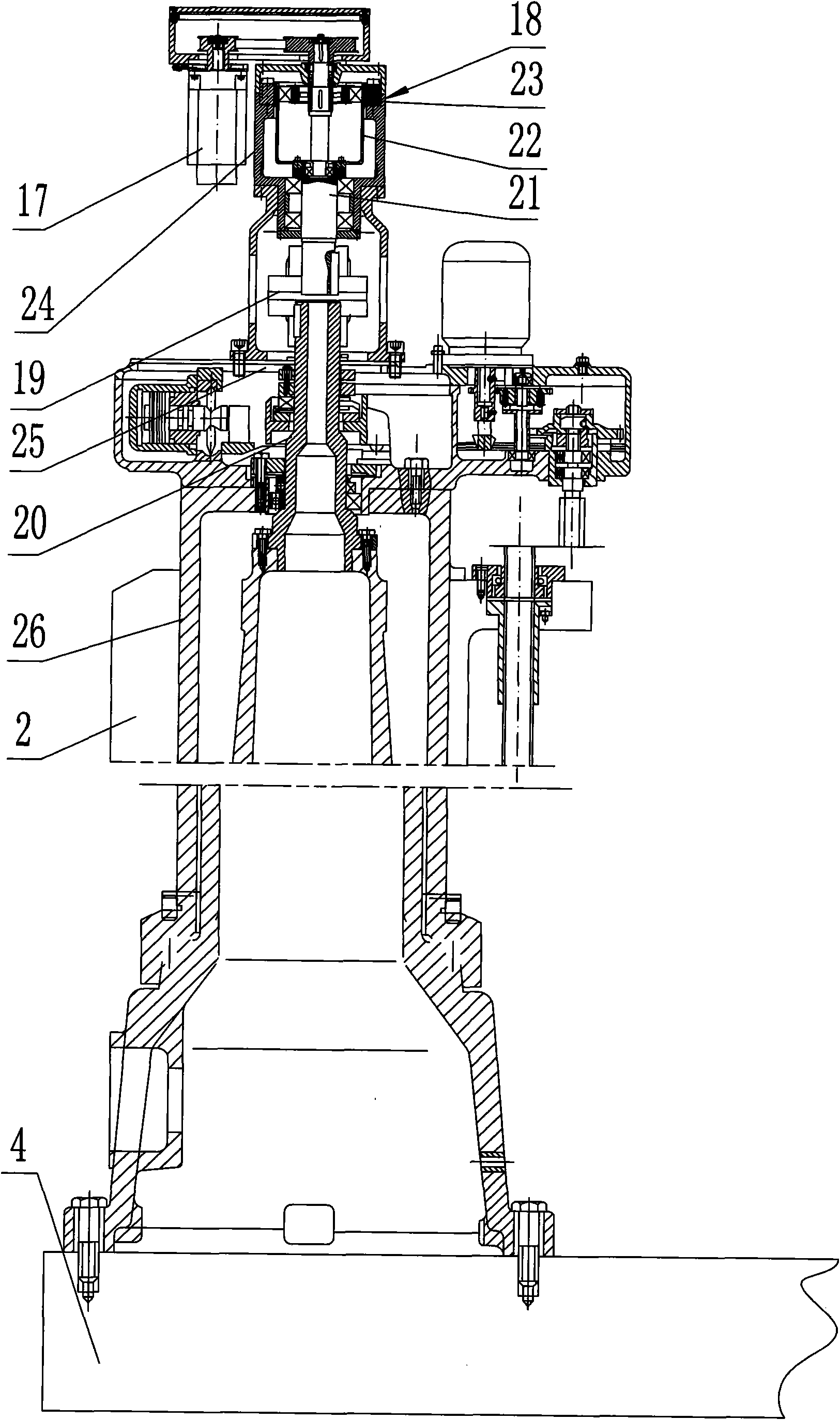

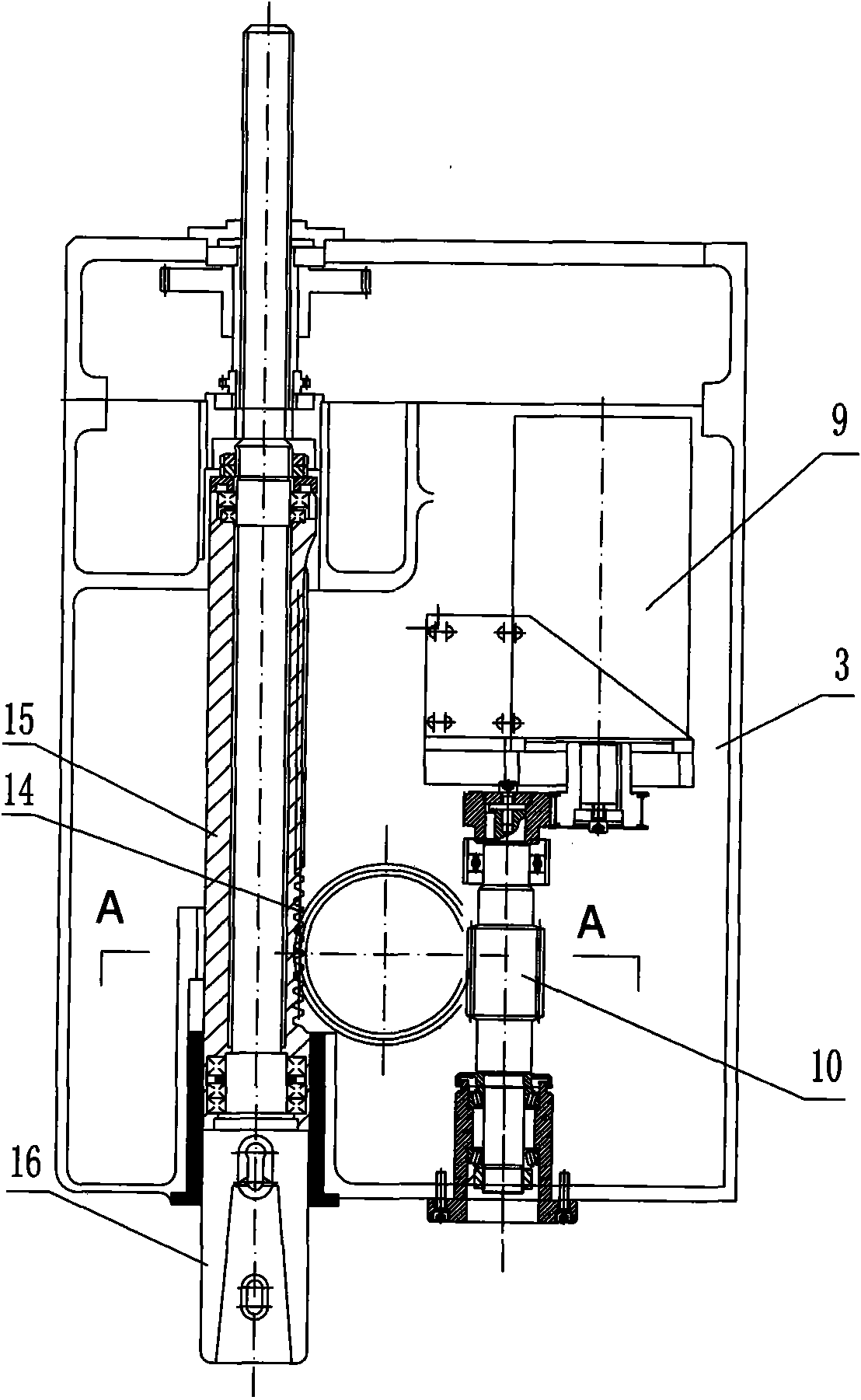

[0016] A CNC radial drilling machine, such as figure 1 As shown, it includes a column 1, a rocker arm 2 installed on the column 1, a spindle box 3 installed on the rocker arm 2, and a base 4 fixedly connected to the bottom of the column 1. Between the spindle box 3 and the rocker arm 2, there is a The spindle box 3 is a numerically controlled drive assembly that moves along the rocker arm 2; the spindle 16 is provided with a numerically controlled drive assembly for spindle speed change and feed; the rocker arm 2 is provided with a numerically controlled drive assembly for swinging the rocker arm.

[0017] Wherein, the spindle box arranged between the spindle box 3 and the rocker arm 2 moves along the numerical control drive assembly of the rocker arm, including a lead screw 5 fixed on the rocker arm 2, the lead screw 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com