Sludge drying system and sludge drying process

A sludge drying and sludge technology, which is applied in solar heating systems, dehydration/drying/concentrated sludge treatment, solar collectors using working fluids, etc., can solve high energy consumption, high investment, and urban sludge It can save energy, improve drying efficiency, and improve sludge drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

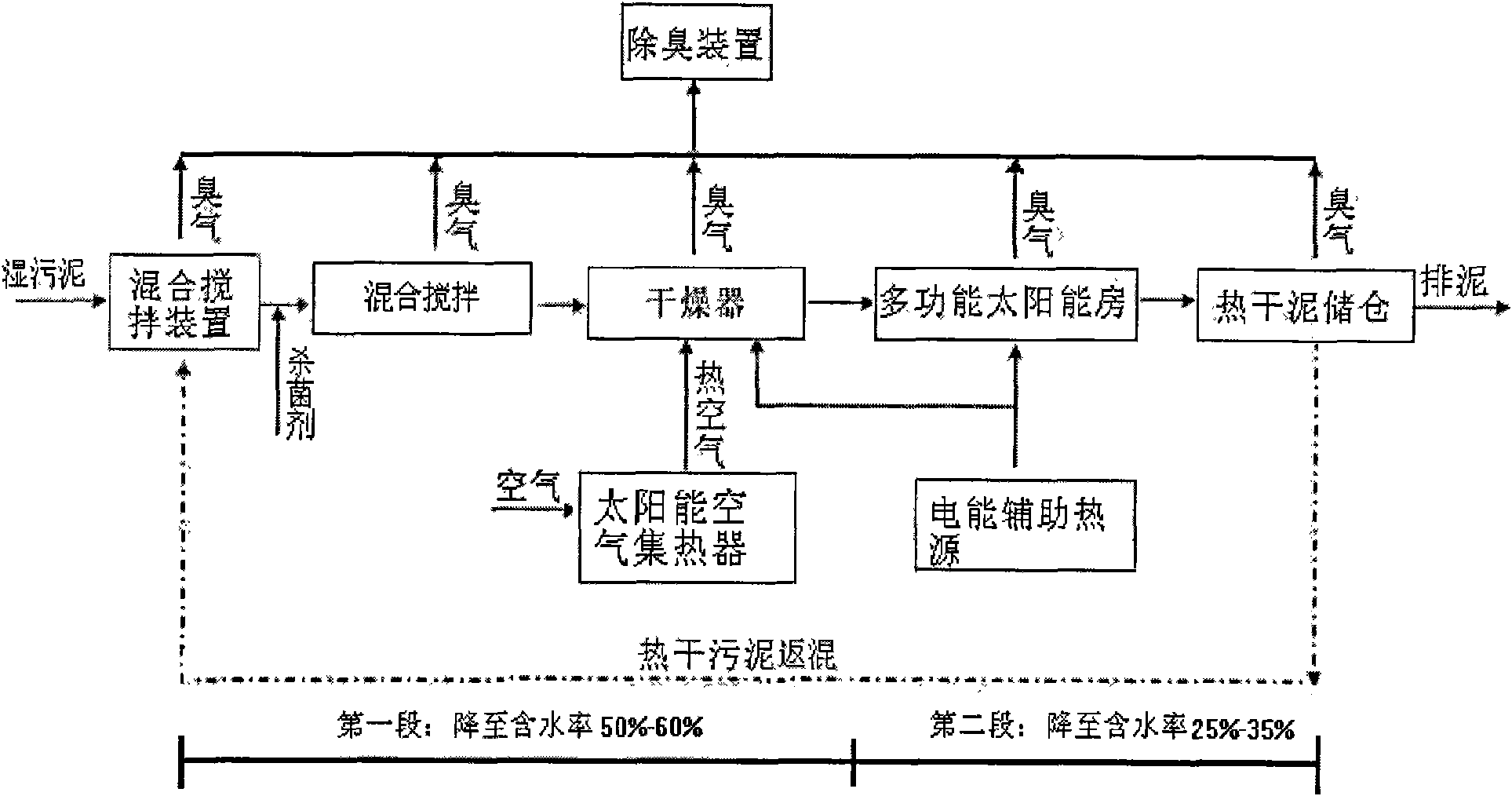

[0036] Process of the present invention such as figure 1 As shown, it proceeds in the following steps:

[0037] (7) Put the wet sludge into the mixing and stirring device for preliminary stirring.

[0038] (8) Spray the bactericide into the mixing and stirring device, and carry out mixing and stirring at the same time.

[0039] (9) Put the sludge treated in (2) into the dryer, and use the hot air generated by the solar air collector to dry the sludge in the first step.

[0040] (10) Put the sludge dried in the first step into the multifunctional solar house for the second step of drying.

[0041] (11) Put the dried sludge product into the hot dry sludge storage bin.

[0042] (12) Return the sludge in the hot dry sludge storage bin to the mixing and stirring device at a ratio of 5%-20%.

[0043] The odor generated in the above pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com