Synchronous continuous support pulling construction method of long and large steel box girder

A construction method and technology of steel box girder, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unsuitable long steel box girder tow erection, difficulty in erection accuracy control, and large deviation as the bridge is longer. , to achieve the effect of saving auxiliary engineering volume and cost, ensuring erection accuracy and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

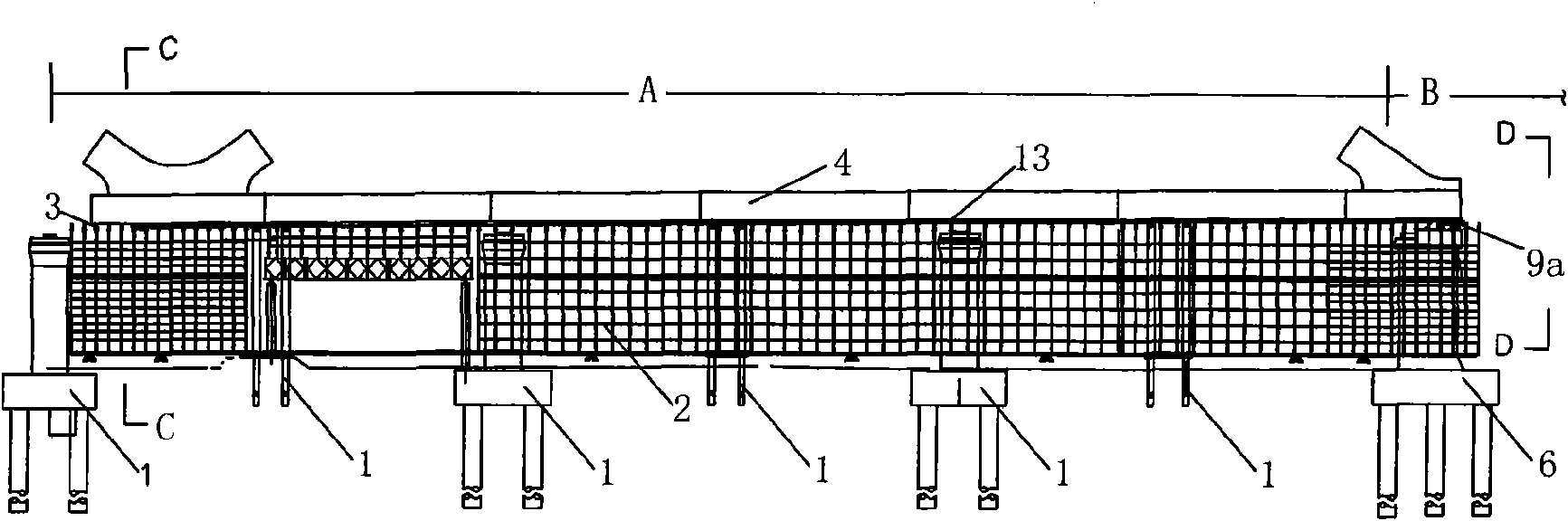

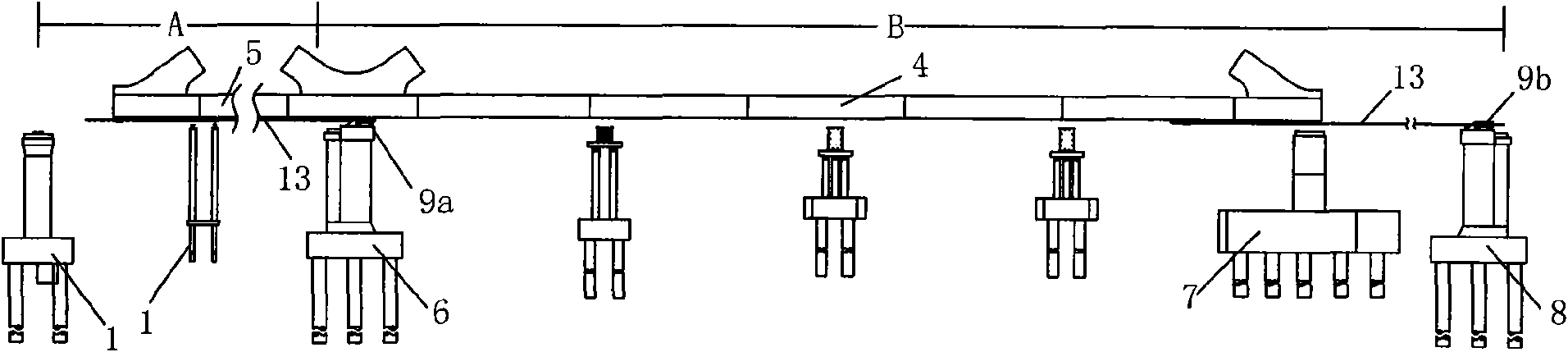

[0030] In this example, figure 1 with figure 2 The area of part A shown in is the simply supported beam area, and the area of part B is the steel box girder area.

[0031] The synchronous continuous jacking construction method adopted for the long steel box girder is carried out according to the following steps:

[0032] ①, figure 1 As shown, in the simply supported beam area at the end of the steel box girder area, along the center line of the steel box girder, a steel box girder assembly composed of simply supported beam area column 1, bowl buckle scaffold 2 and horizontal mold 3 is set. Support; assemble the first steel box girder 4 on the steel box girder assembly support;

[0033] ②, figure 1 , figure 2 As shown, on the No. 1 pier 6 in the steel box girder area, two No. 1 jacks 9a that can work synchronously are installed symmetrically along the center line of the bridge;

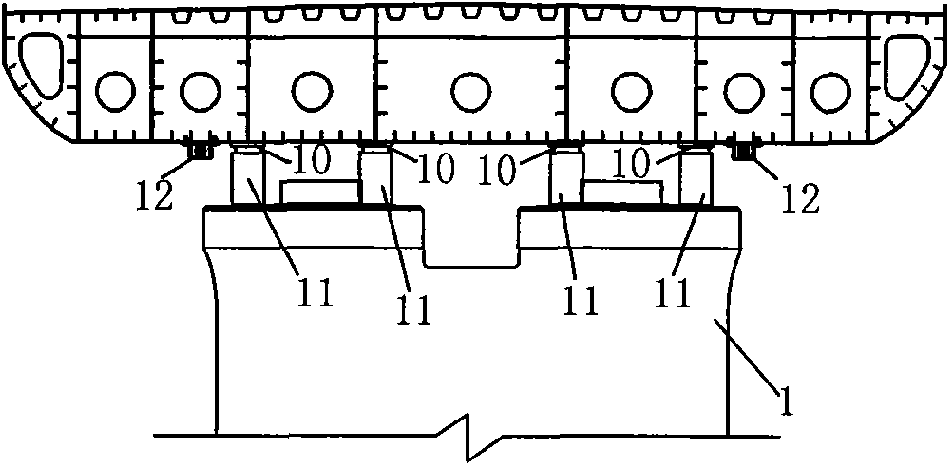

[0034] ③, image 3 , Figure 4 As shown, the slideway is set, including the upper sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com