Urinary cell micro staining analysis method

An analysis method and quantitative analysis technology, applied in the field of medical inspection, can solve the problems of waste of dye solution, inability to achieve individualized dyeing of a single sample, and inability to implement micro-control of dye solution dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Example 1 Urine Cell Analysis

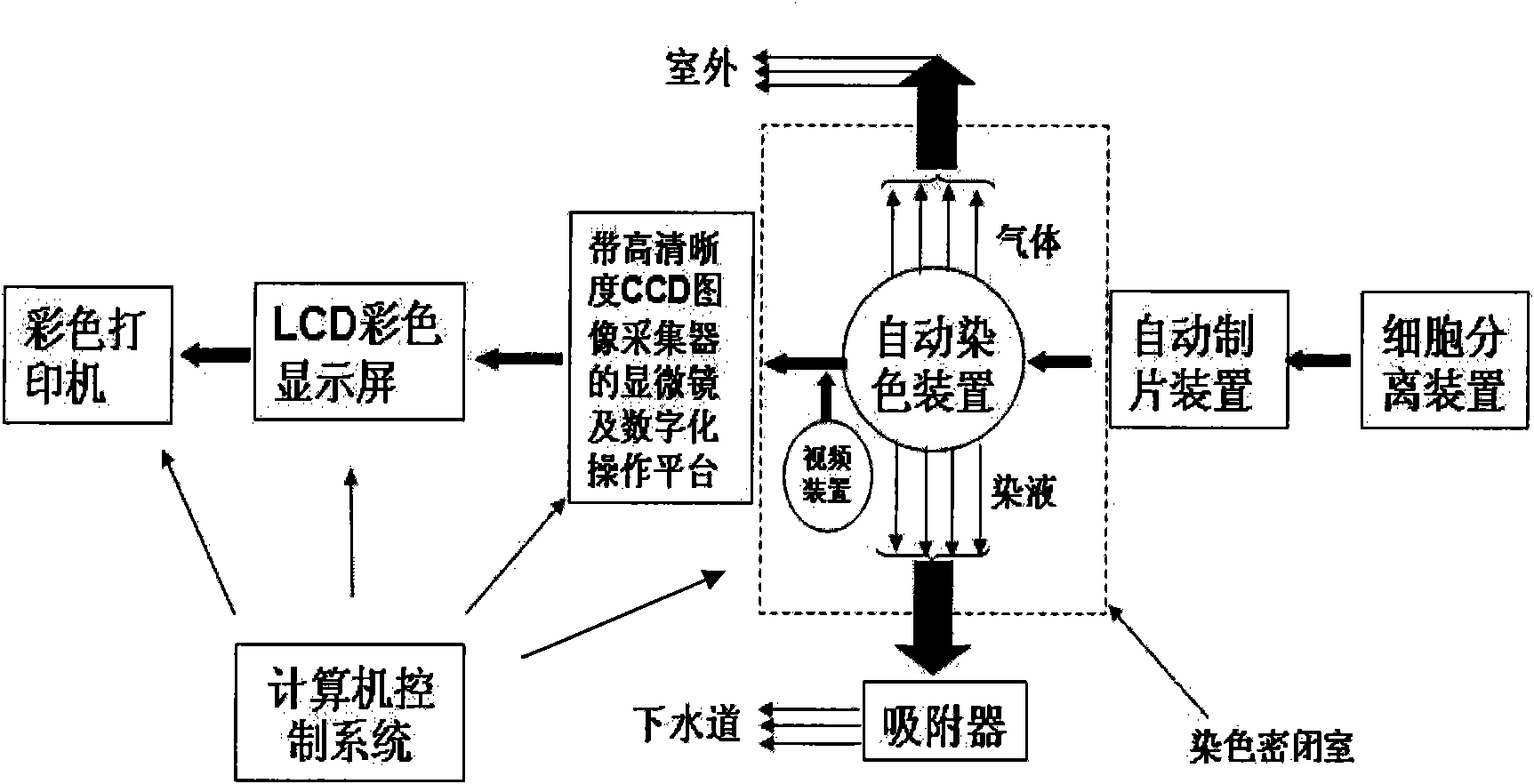

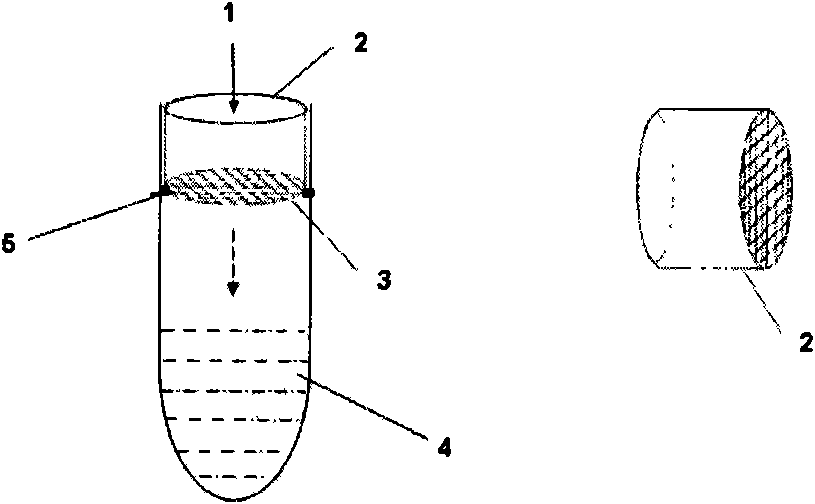

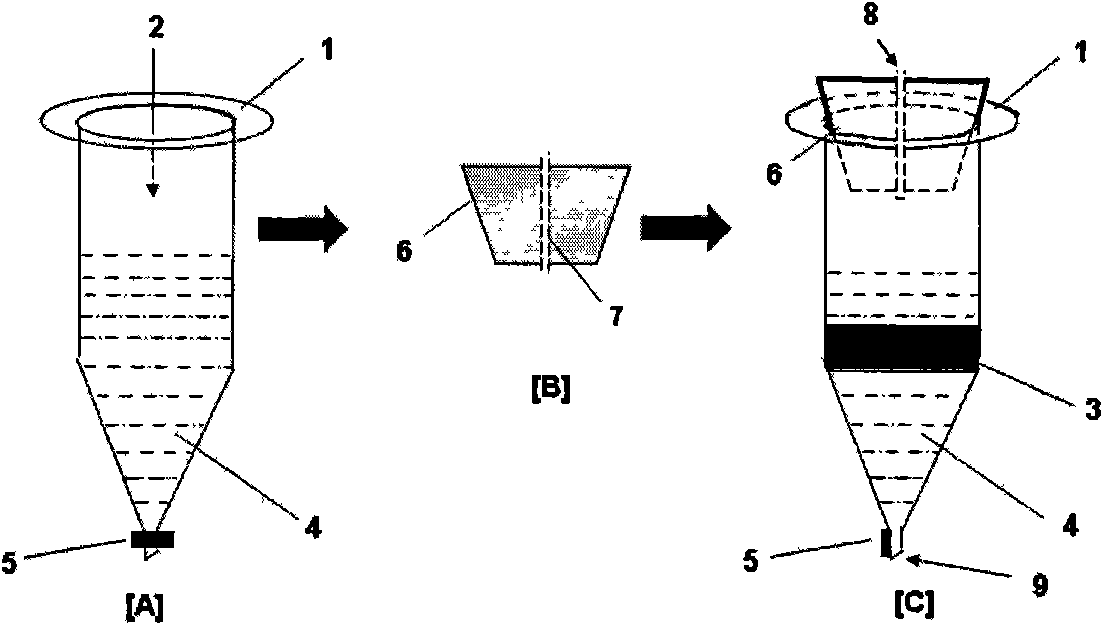

[0136] 10-50ml of fresh urine was centrifuged at 2000rpm for 10min, the sediment was mixed with 1ml of Hanks solution, and passed through a 30-300 mesh filter ( figure 2 , 3), in the centrifuged state, slowly inject 1ml of urine sediment Hanks solution into a continuous density gradient test tube prepared by Ficoll at 1.095-1.055g / ml, suck out the layered cell mass, centrifuge at 2000rpm for 10min, and use 0.5ml Hanks solution to weigh hanging. After diluting the sample with Hanks solution, take 200μl urine cell sample and add 3-8ml Ficoll (1.065g / ml) solution to mix well, then transfer it to a clean cell flake device, and centrifuge at 3000rpm for 5min to automatically make a thin cell sheet ( Figure 4 , 5). Fix with absolute ethanol and dry before use. When staining, place 1 slide in the automatic staining device[ Figure 6 , 7] in the staining tank, input each staining program respectively, such as Papanicolaou staining, then the...

Embodiment 2

[0162] Example 2 Urine Cell Analysis

[0163] 10-50ml of fresh urine was centrifuged at 2000rpm for 10min, the sediment was mixed with 1ml of Hanks solution, and passed through a 30-300 mesh filter ( figure 2 , 3), in the centrifuged state, slowly inject 1ml of urine sediment Hanks solution into a continuous density gradient test tube prepared by Ficoll at 1.095-1.055g / ml, suck out the layered cell mass, centrifuge at 2000rpm for 10min, and use 0.5ml Hanks solution to weigh hanging. After diluting the sample with Hanks solution, take 200μl urine cell sample and add 3-8ml Ficoll (1.065g / ml) solution to mix well, then transfer it to a clean cell flake device, and centrifuge at 3000rpm for 5min to automatically make a thin cell sheet ( Figure 4 , 5). Fix with absolute ethanol and dry before use. When staining, place 24 slides in the automatic staining device[ Figure 6 , 7] in the staining tank, input each staining program respectively, such as Papanicolaou staining, then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com