Manufacturing process of stator

A manufacturing process and stator technology, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as excessive energy consumption, large equipment investment, and extremely high metallographic requirements, and achieve the goals of improving production efficiency, ensuring output quality, and improving strength indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0025] The process route of the present invention is: cutting → annealing → billet making → lubrication → extruding holes → extruding teeth

[0026] (1) Blanking: CNC band sawing machine is used for blanking, the verticality is less than or equal to 0.3

[0027] (2) Annealing: use a well-type vacuum annealing furnace to evacuate and fill with nitrogen for protection annealing. After annealing, the oxidative decarburization unilateral is less than or equal to 0.1, and the hardness of the material after annealing is HB113-120.

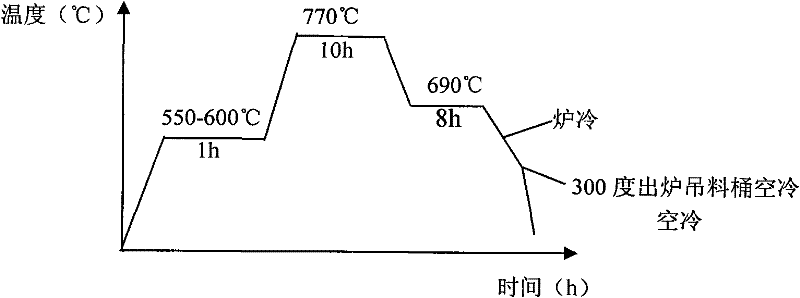

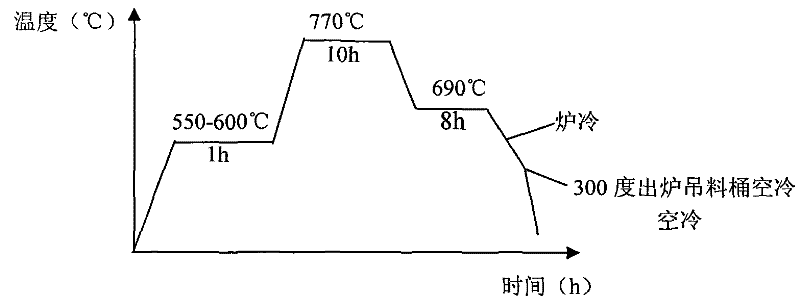

[0028] 20CrMnTi spheroidizing annealing process:

[0029] like figure 1 , Requirements: 1. Heating rate <150℃ / h, cooling rate <50℃ / h;

[0030] 2. Pre-vacuum, fill with nitrogen after each pumping, the pressure is ≥ 0.01Mpa;

[0031] 3. The annealed metallographic structure is F+P ball, and the grade is 4-6

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com