Film-forming material, crosslinkers and coating compositions containing silane, methods for producing a coating composition and a coated substrate

A technology of film-forming substance and alkyl, which is applied in the direction of coating, can solve the problems of consuming a lot of time and energy, and achieve the effect of saving operation time and energy and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Synthesis of Silane-Containing Film-Forming Resins

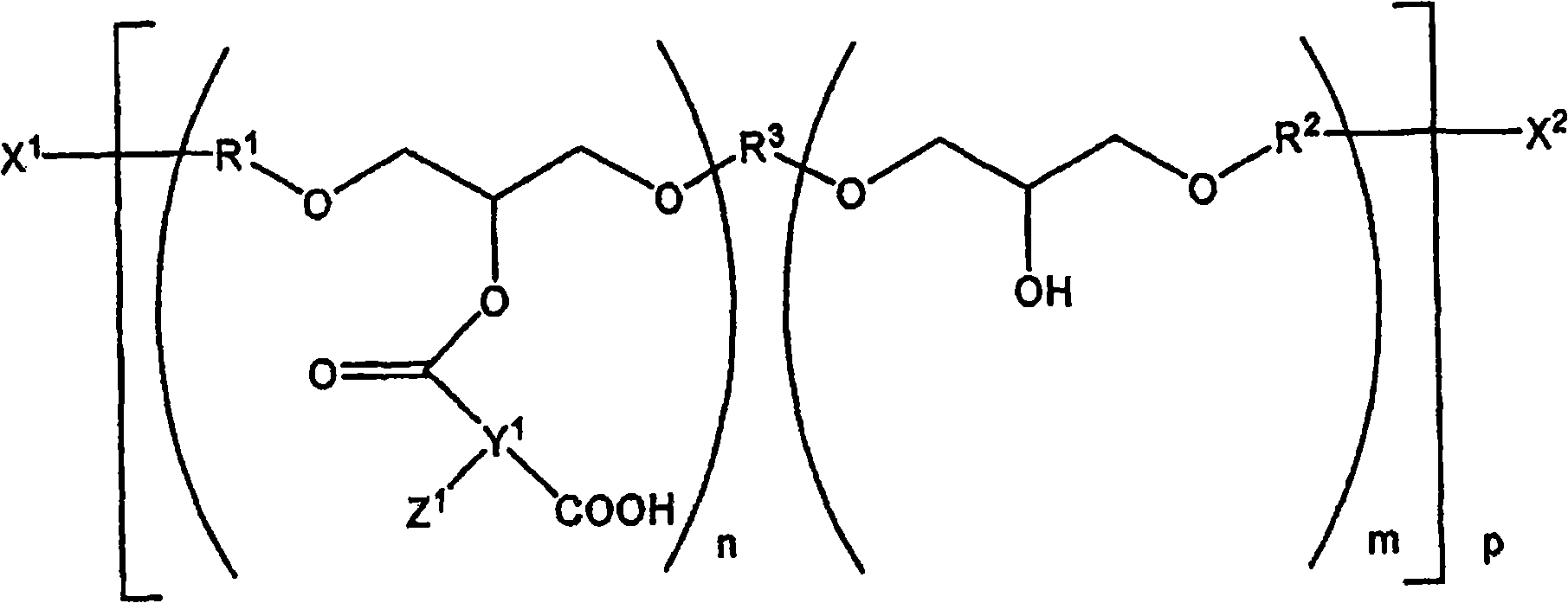

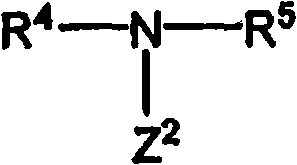

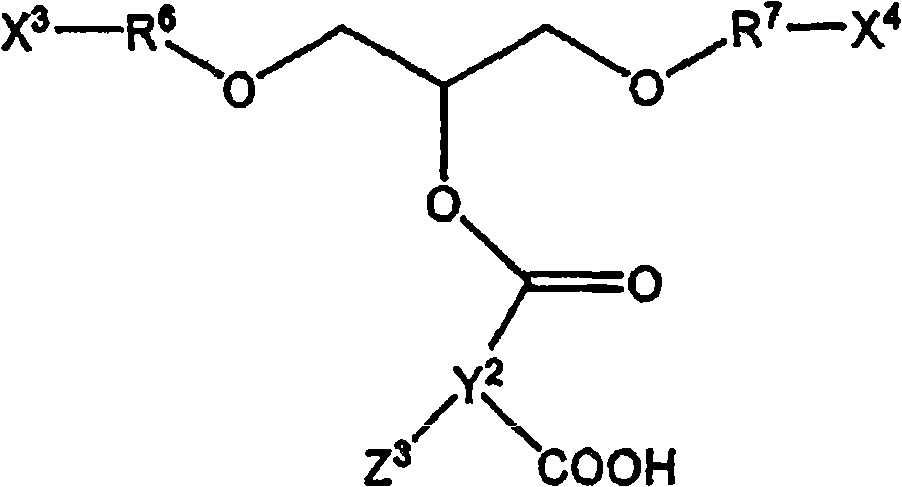

[0094] have at least one containing -Si(OR) 3 The film-forming resin of the side group of the group is synthesized by a four-step method. The first step is the synthesis of the resin polymer backbone. Diglycidyl ether of bisphenol A, bisphenol A, solvent, phenol and catalyst are mixed and reacted to prepare a hydroxyl polymer, and the monomer unit link of the hydroxyl polymer contains hydroxyl groups on both sides of the ether bond. The second step is amine capping by reacting the hydroxyl polymer with primary or secondary amines, including aminoorganotrialkoxysilanes, to introduce -Si(OR) 3 base. The third step involves a grafting reaction between the capped hydroxyl polymer and the carboxylic anhydride, wherein the carboxylic anhydride has ethylenically unsaturated groups. The carboxylic anhydride reacts with the hydroxyl groups of the polymer to create an ester linkage between the aforementioned anhydride and the polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com