Complete nutrition powder using beer yeast as main material and processing method

A technology of brewer's yeast and main raw materials, applied in the field of complete nutritional powder and its processing, can solve the problems of incomplete nutrition, single nutrition, poor taste, etc., and achieve the effects of convenient taking, overcoming single nutrition, and no toxic and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1 Obtaining of pure yeast powder:

[0024] 1) Obtaining pure yeast mud---Debittering and impurity removal of brewer's yeast:

[0025] After 200kg of waste yeast was washed 3 times with 800L of clear water at 15°C, washed once with 500L of 5% NaCl solution, and the solid was collected by centrifugation to obtain 187kg of pure yeast mud debittered and impurity removed;

[0026] 2) Heating autolysis treatment of pure yeast mud:

[0027] Add 187kg of pure yeast mud to 400L of pure water, stir evenly, heat to 40-50°C, adjust pH to 5.5, and keep the temperature for 15 hours to accelerate autolysis;

[0028] 3) Sterilization and inactivation of enzymes:

[0029] After autolysis, it was heated to 95°C for 20 minutes for sterilization and enzyme inactivation;

[0030] 4) Drying of pure yeast puree:

[0031] The above-mentioned about 590kg pure yeast mud is spray-dried to obtain 52kg pure yeast powder;

example 2

[0033] Nutritional analysis of pure yeast powder:

[0034] The analysis results of the dried brewer's yeast components are shown in Table 1 and Table 2

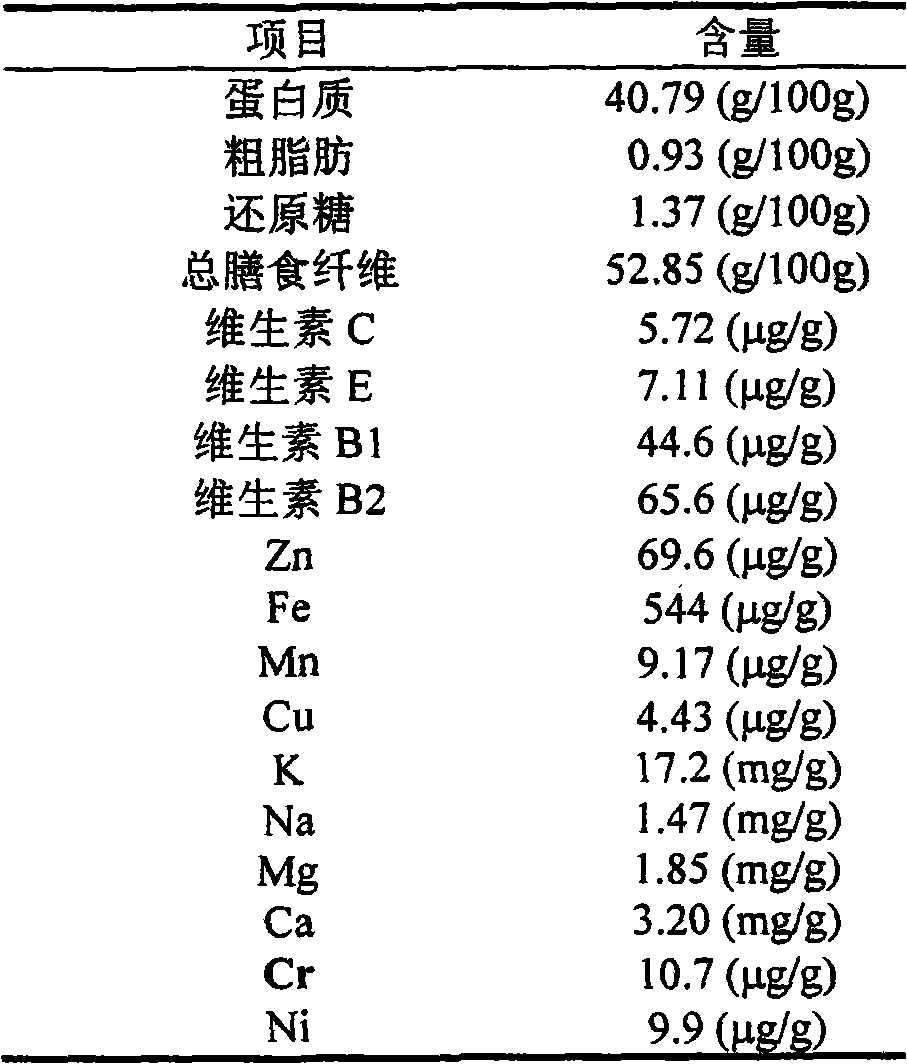

[0035] Table 1 Composition of spray-dried pure yeast puree

[0036]

[0037]

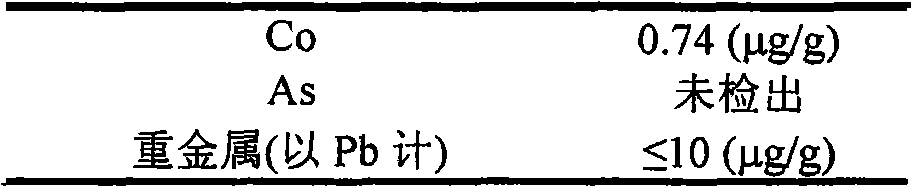

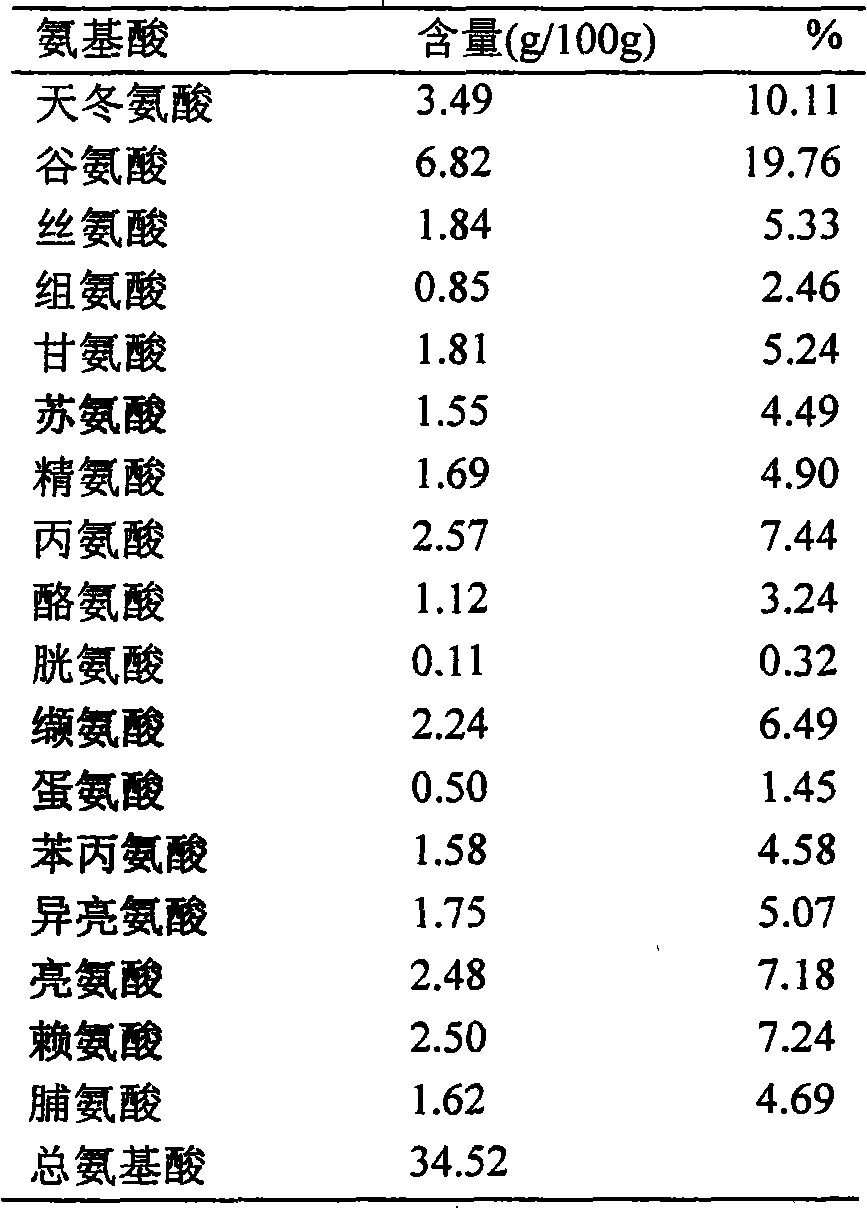

[0038] Table 2 Amino acid composition of spray-dried pure yeast puree

[0039]

[0040] The composition analysis of the dried pure beer yeast powder showed that among the 8 kinds of amino acids necessary for human body, except tryptophan, the other 7 kinds were abundant. In addition, the energy material is slightly deficient and cannot fully meet the needs of the human body. After adding necessary substances, it can be made into a complete nutritional powder.

example 3

[0042] Preparation of Whole Nutrition Powder (Formula 1):

[0043] 1. The parts by weight of each ingredient: take 7 parts of pure yeast powder, 0.85 part of red bean powder, 0.75 part of walnut powder, 0.45 part of low-fat cocoa powder, 0.65 part of vanillin, and 0.3 part of stevia essence;

[0044] 2. Bake in an oven at 110-115°C for 10 minutes to achieve the purpose of short-term sterilization;

[0045] 3. Put the ingredients into the blender and stir for 10 minutes, and mix well.

[0046] 4. Pack the mixed powder into small packages of 30g / pack to become weight loss complete nutrition powder.

[0047] Recommended way to eat:

[0048] Take a small sachet of this product with breakfast and brew it with warm water below 40°C. This product can be eaten alone or with milk, soy milk, honey, fruit, etc.;

[0049] Half an hour before lunch, take a small sachet of this product and brew it with warm water below 40°C. Lunch is unlimited.

[0050] Half an hour before dinner, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com