Hydrogel formulation polymerized at normal temperature and preparation method

A production method and hydrogel technology, applied in the chemical industry, can solve the problems of high production difficulty and high production cost, no discussion of polymerization formula and production method, etc., so as to reduce production process requirements and costs, and reduce acid-base concentration , the effect of facilitating miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

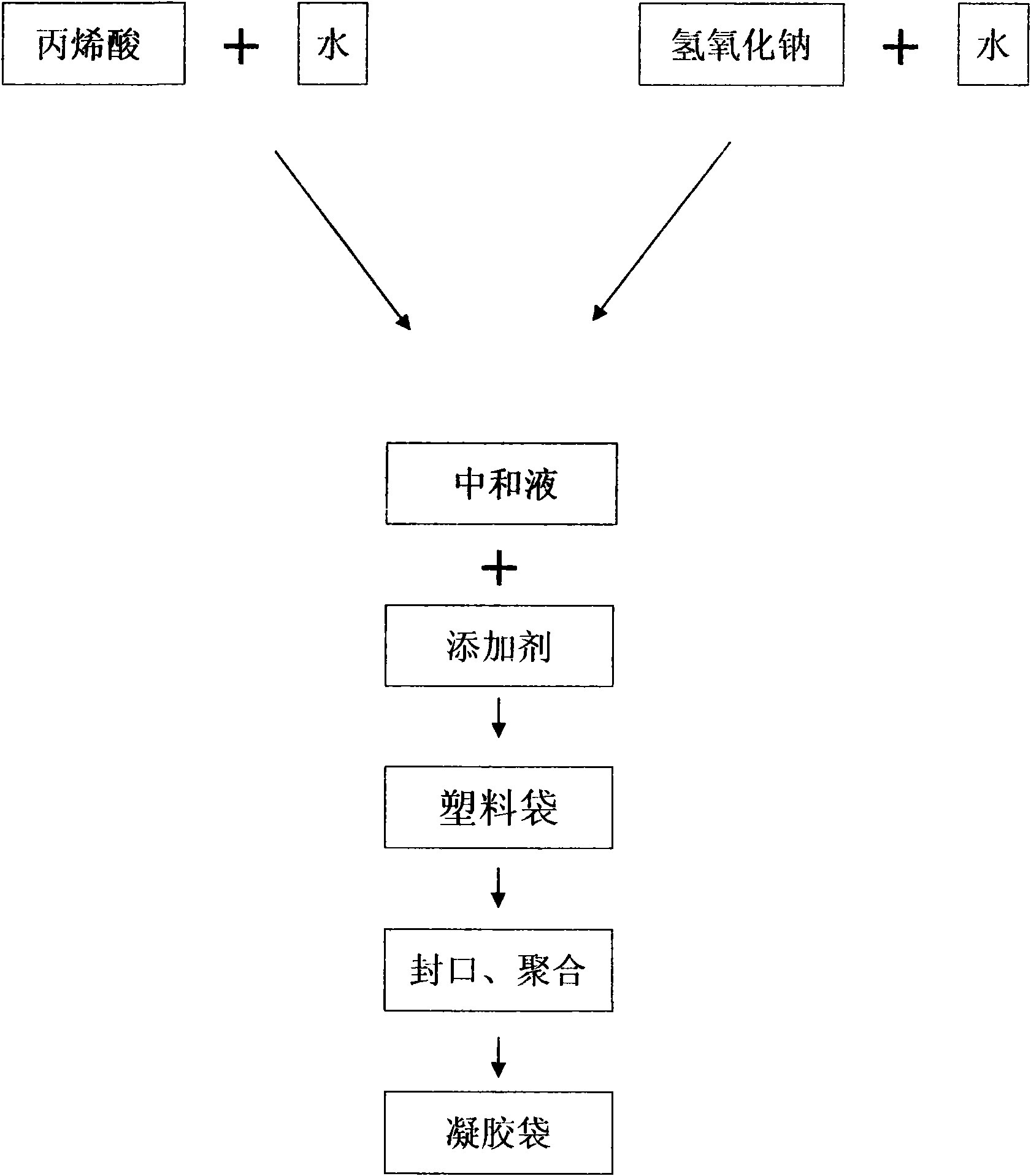

Method used

Image

Examples

Embodiment 1

[0009] Example 1, 100g sodium hydroxide and 900ml water are dissolved for subsequent use, and 1000ml of acrylic acid aqueous solution 1000ml is stirred and neutralized, and the maximum temperature of the neutralized solution is recorded as 33 degrees, and then the prepared additive is added (wherein the initiator is put at the end ), and finally pour the liquid to be polymerized into the plastic bag, exhaust and seal it and let it stand for polymerization. The polymerization time can be adjusted in the range of 2-120 minutes by adjusting the ratio of additives, and the polymerization temperature is 28-30 degrees, depending on the needs of the product. Certainly. The polymerized hydrogel is crystal clear, elastic, non-dripping, non-deformable, and will not dissolve when scalded with boiling water or heated in a microwave oven, which simplifies the production process of the hydrogel bag and improves the quality and use effect of the hydrogel bag. After the polymerized hydrogel i...

Embodiment 2

[0010] Example 2, 100g of sodium hydroxide and 1100ml of water were dissolved for later use, stirred and neutralized with 1200ml of 9% acrylic acid aqueous solution, and the highest temperature of the neutralized solution was measured to be 29 degrees, and it could also be cooled naturally. Then add the prepared additives, and finally pour the liquid to be polymerized into ceramic bowls and let it stand for polymerization. The polymerization temperature is within 25 degrees. After the polymerized hydrogel is dehydrated and dried, it is pulverized into a water-absorbing resin with a water absorption rate of 80 times.

Embodiment 3

[0011] Example 3, 100kg of sodium hydroxide and 600kl of water are dissolved for subsequent use, and neutralized with 700kl of 15% acrylic acid aqueous solution by stirring. The highest temperature of the neutralized solution is measured to be 40 degrees, and it can also be cooled naturally. Then add the prepared additives, and finally pour the liquid to be polymerized into plastic trays and let it stand for polymerization. The polymerization temperature is within 37 degrees. After the polymerized hydrogel is dehydrated and dried, it is pulverized into a water-absorbing resin with a water absorption rate of 160 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com