Processing method for connecting micro coaxial cable and connector

A processing technology, coaxial technology, applied in connection, assembly/disassembly of contacts, circuit/collector parts, etc., can solve the problems of low precision, affecting electrical signal transmission, unreliable mechanical connection of lines, etc. Achieve the effect of high precision, stable line connection and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

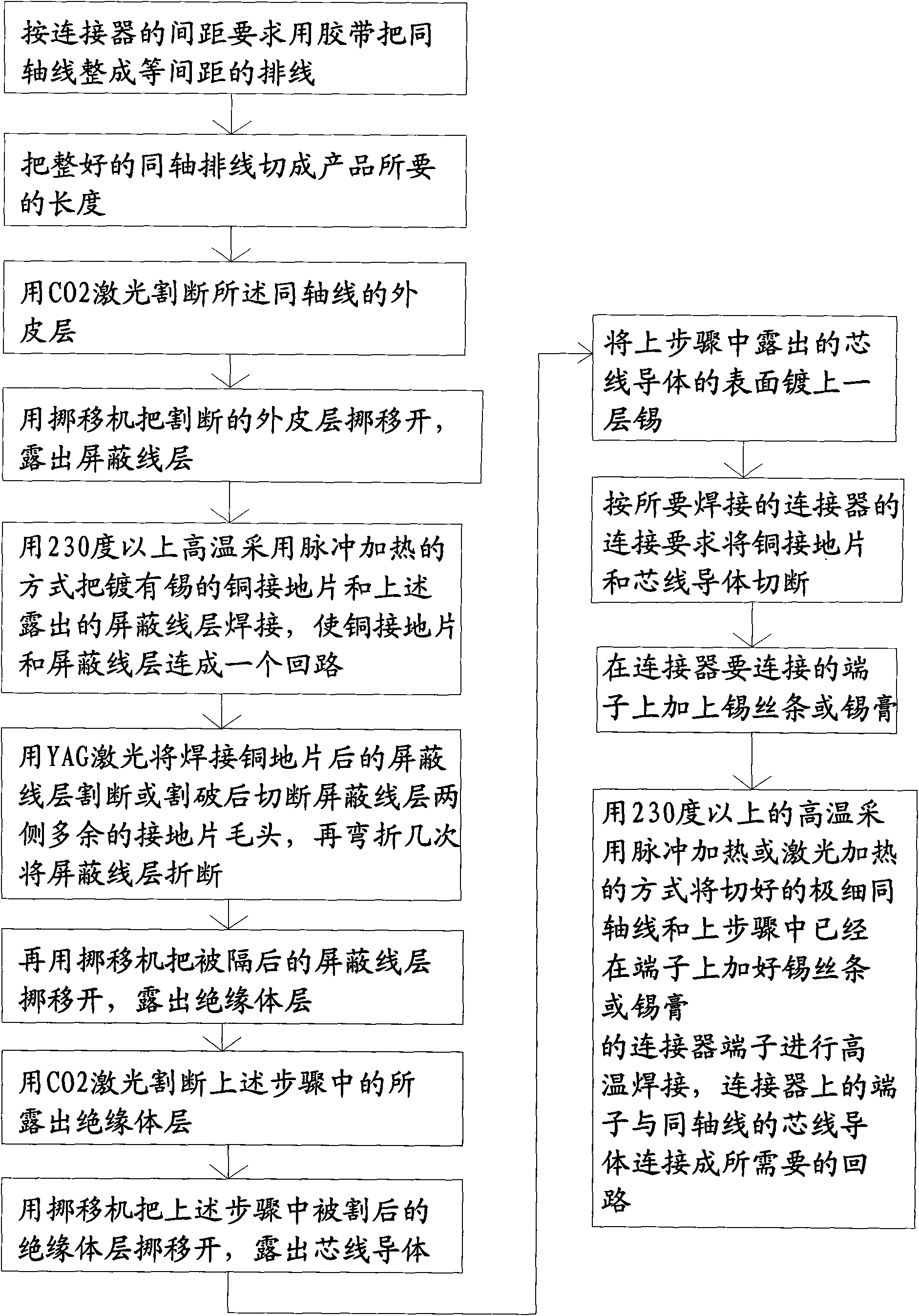

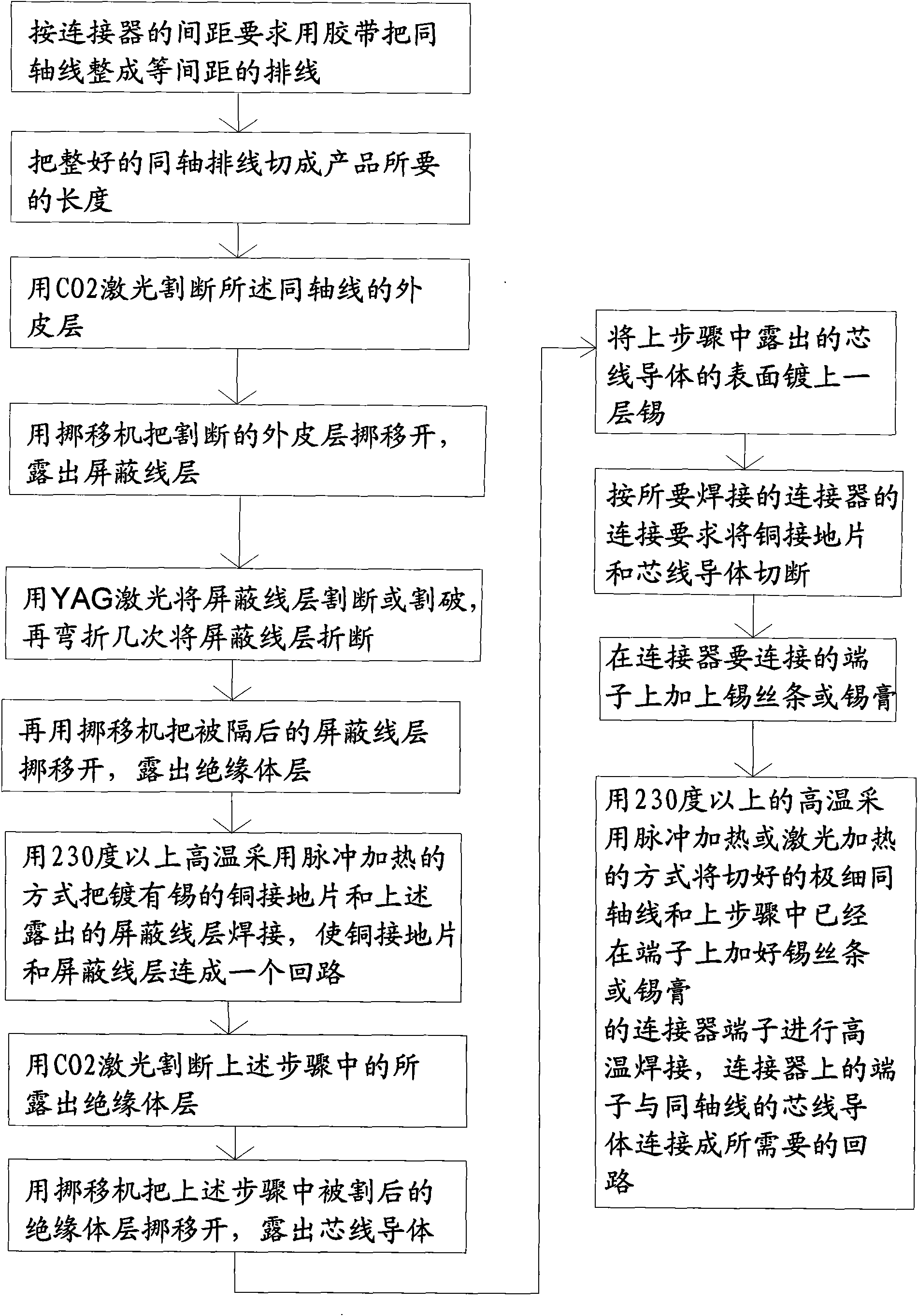

[0047] Most of the ultra-thin coaxial cables are composed of multi-layer wires, including outer skin layer, shielding wire layer, insulator layer and core wire conductor layer from outside to inside. The first embodiment of the processing method of welding the ultra-thin coaxial cable and the connector (including the flexible circuit board FPC / circuit board PCB) of the present invention includes the following steps in sequence:

[0048] (1). According to the spacing requirements of the connectors to be connected, use tape to glue the coaxial cables into equal-spaced cables with a spacing of 0.2mm to 1.5mm;

[0049] (2). Cut the glued coaxial cable into the desired length of the product;

[0050] (3). Using CO 2 Cutting off the outer cortex of the coaxial line described in step (2) by laser;

[0051] (4). Use a moving machine to remove the outer skin layer cut off in step (3) to expose the shielding wire layer;

[0052] (5). Use pulse heating or laser heating at a high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com