Method for preparing 3-ammoniac methyl-3-methyl trimethylene oxide

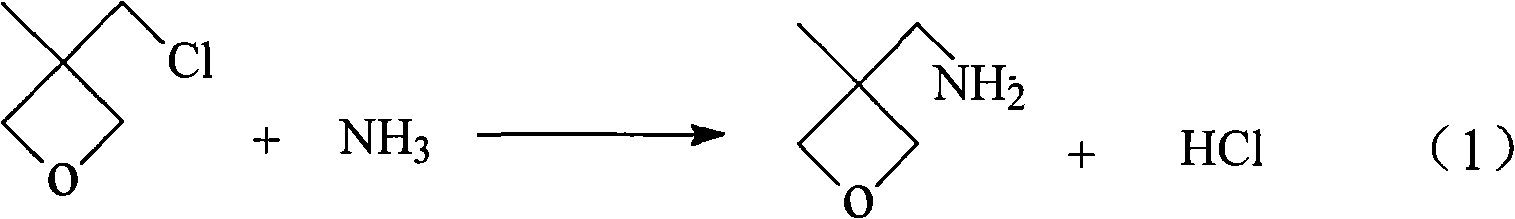

A technology of methyl oxetane and aminomethyl, applied in the field of preparation of 3-aminomethyl-3-methyl oxetane, which can solve the problems of lengthy process, many reaction steps, and tediousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, add 121g CMMO (1mol) to the 1.5L high-pressure ammoniation reactor, high-purity N 2 After sufficient replacement, press 375g of liquid ammonia (22mol) into the reaction kettle with high-purity nitrogen of 0.6-0.70MPa. Heating and stirring, the temperature in the kettle is raised to 80℃~85℃, and the pressure is increased from 0.6MPa to 3.3~3.5MPa. After reacting at this temperature and pressure for 9 hours, the material in the kettle is cooled to room temperature. Lead unreacted excess liquid ammonia into an absorption bottle filled with a sufficient amount of 25% sulfuric acid solution, and empty it after absorption. Then, add 400ml of ethanol to the kettle, stir, and discharge the material. The material is cooled to 0-5°C. A large amount of white crystals of ammonium chloride appear in the solution. Filter and collect the filtrate. Ethanol is removed by evaporation under normal pressure until the solution temperature When the temperature rises to ...

Embodiment 2

[0024] At room temperature, add 121g CMMO (1mol) to the 1.5L high-pressure ammoniation reactor, high-purity N 2 After sufficient replacement, 410 g of liquid ammonia (24 mol) was pressed into the reaction kettle using 0.6-0.70 Mpa of high-purity nitrogen. Heating and stirring, the temperature in the kettle is raised to 80℃~85℃, and the pressure is increased from 0.6MPa to 3.3~3.5MPa. After reacting at this temperature and pressure for 10 hours, the material in the kettle is cooled to room temperature, and the unreacted The excess liquid ammonia is introduced into an absorption bottle filled with a sufficient amount of 25% sulfuric acid solution, and is emptied after absorption. Then, add 400ml of methanol to the kettle, stir, and discharge the material. The material is cooled to 0-5°C. A large amount of white crystals of ammonium chloride appear in the solution. Filter and collect the filtrate. Evaporate and remove methanol under normal pressure until the solution temperature ...

Embodiment 3

[0026] At room temperature, add 121g CMMO (1mol) to the 1.5L high-pressure ammoniation reactor, high-purity N 2 After sufficient replacement, 410 g of liquid ammonia (24 mol) was pressed into the reaction kettle using 0.6-0.70 MPa high-purity nitrogen. Heating and stirring, the temperature in the kettle is raised to 80℃~85℃, and the pressure is increased from 0.6MPa to 3.3~3.5MPa. After reacting at this temperature and pressure for 10 hours, the material in the kettle is cooled to room temperature, and the unreacted The excess liquid ammonia is introduced into an absorption bottle filled with a sufficient amount of 25% sulfuric acid solution, and after absorption, it is emptied. Then, add 400ml of diethyl ether and stir, discharge the material, cool the material to 0-5°C, a large amount of white crystals of ammonium chloride appear in the solution, filter, collect the filtrate, evaporate and remove the ether under normal pressure, until the temperature of the solution rises to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com