Deep sea cable

A cable and deep-sea technology, applied in the cable field, can solve the problems of inability to realize joints, and achieve the effects of superior wear resistance, high strength, and increased tensile strength

Inactive Publication Date: 2010-02-03

JIULI ROPE

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the largest eight-strand braiding machine in China, the single weight of each rope does not exceed 2 tons, and the existing mechanical equipment cannot achieve joints. At the same time, the breaking force of each rope can only reach a maximum breaking force of 300 tons.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

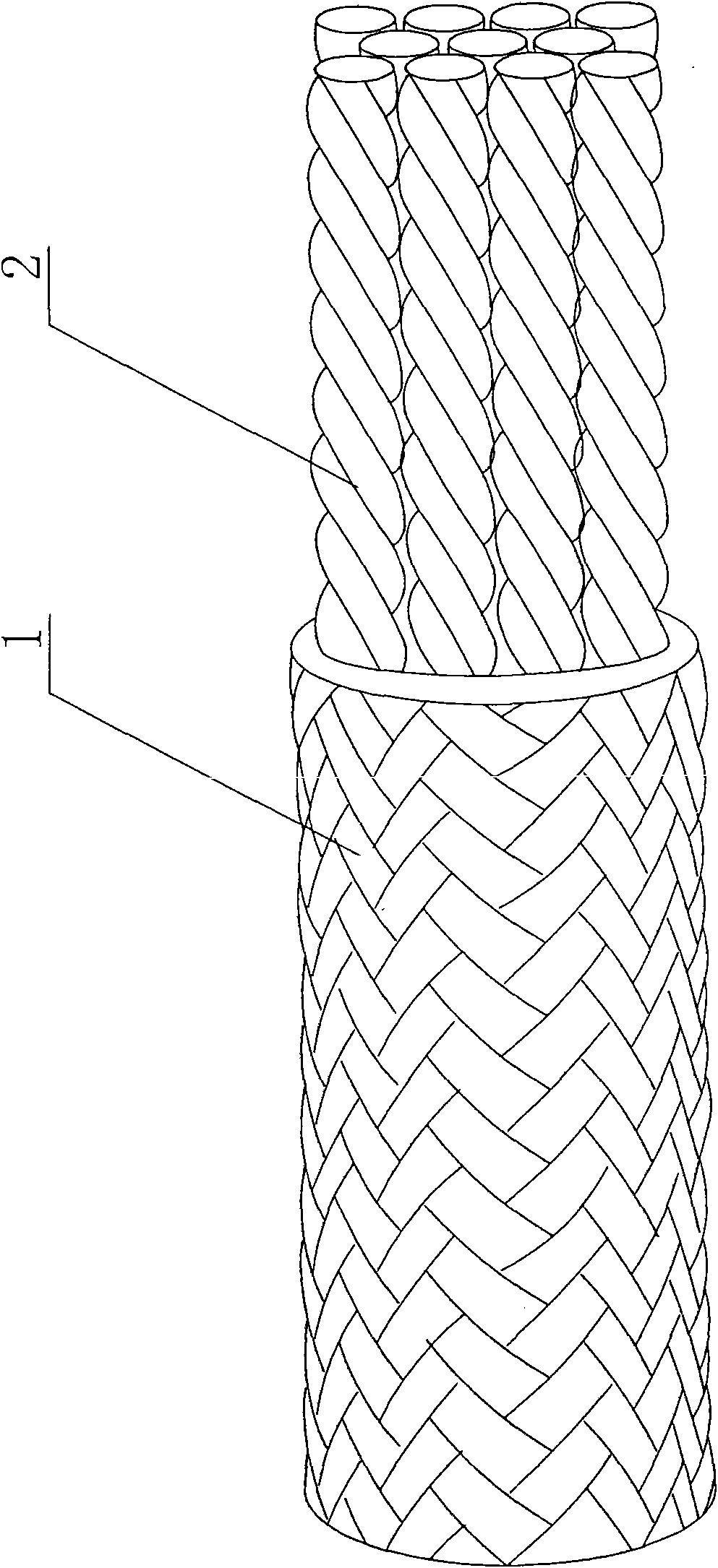

[0010] As shown in the figure, it is a deep-sea cable, including a cable core bundle 2 composed of several cable cores. Each cable core is twisted by three strands of high-strength high-modulus polyethylene fibers. Thirty-two strands of nylon multifilament are woven.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a deep sea cable, which belongs to the technical field of cables. The deep sea cable comprises a cable core bundle consisting of a plurality of cable cores, wherein each cablecore is twisted by using three stands of high-strength high-modulus polyethylene fibers; and an outer coverage layer woven by 32 stands of high-strength polyamide multifilament is arranged on the periphery of the cable core bundle. The excellent wear and corrosion resistance of the high-strength polyamide multifilament ensures the excellent wear-resistance, sea water corrosion-resistance and ultraviolet radiation-resistance performance of the whole cable; the ultra high strength of the high-strength high-modulus polyethylene fibers increases the tensile strength of the cable and meets the requirements on ultra high strength of the deep sea cable; and the cable cores can be manufactured by a multi-length small-diameter connector-free ultra-long process that ensures that the whole cable is made long enough, avoids connectors and meets the requirements on the ultra high strength of the deep sea cable. The deep sea cable is high in strength, light in weight, wear resistant and corrosion resistant and can be applied to off-shore operation, in particular to oil exploration platforms.

Description

technical field [0001] The invention relates to a cable, in particular to a cable used by an oil drilling platform. Background technique [0002] As an important strategic resource, oil has been valued more and more by many countries. With the depletion of land resources, everyone is looking at the deep sea, so deep sea oil exploration must be carried out. [0003] In recent years, with the continuous improvement of my country's economic strength and the long-term strategic demand for oil, our country has also put the development and exploitation of deep-sea oil fields in a very important position. [0004] During the exploration of deep-sea oilfields, the oil exploration drilling platform needs to be moved frequently, which must be achieved with the help of deep-sea cable towing. At the same time, during the exploration process, the drilling platform must be fixed with cables, and this The cable must have super high strength and super long length. Generally, the length of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D07B1/00D07B1/12

CPCD07B1/025D07B2201/1092D07B2201/209D07B2205/2014D07B2205/2046D07B2501/2061D07B2801/10D07B2801/22

Inventor 戴斌

Owner JIULI ROPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com