High stable enhanced colour rendering LED light source module

An LED light source and color rendering technology, applied in the field of LED light source modules with enhanced color rendering, can solve the problems of decreased luminous flux, difficult to stabilize color temperature, inconsistent attenuation coefficient, etc., to eliminate ratio errors, improve color rendering index, and ensure high The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

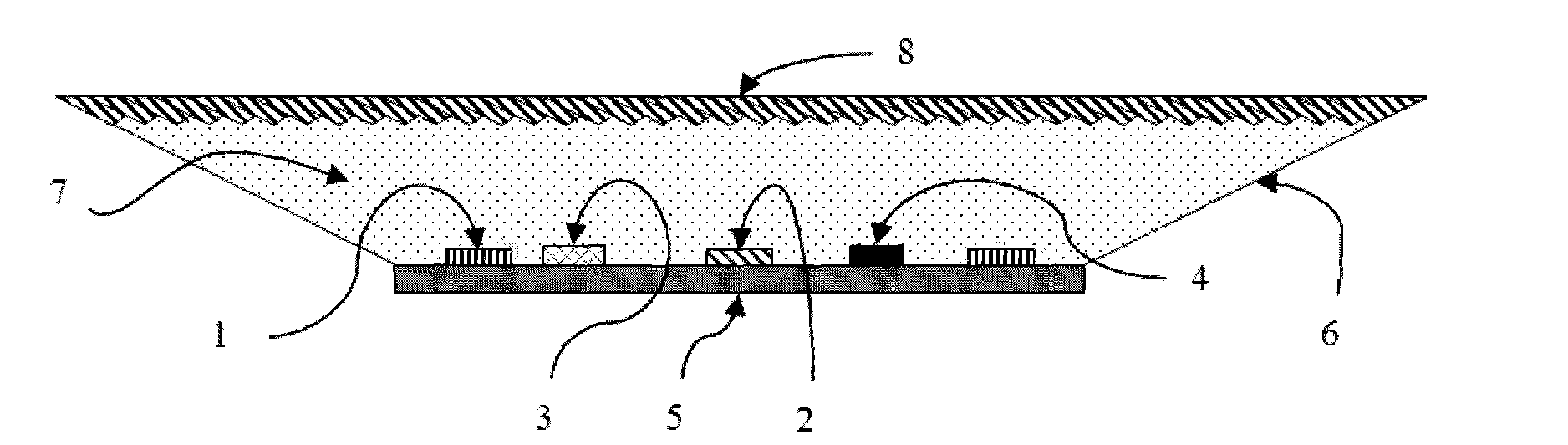

[0026] Such as figure 1 As shown, a highly stable red light enhanced color rendering LED light source module includes a white LED chip 1, a red LED chip 2, a light sensor 3, a temperature sensor 4, a substrate 5, a light mixing cavity 6, a first transparent The optical medium 7 and the second optically transparent medium 8 . The white LED chip 1 is a blue LED chip coated with a YAG phosphor layer.

[0027] A white LED chip 1 , a red LED chip 2 , a light sensor 3 and a temperature sensor 4 are welded on the substrate 5 at the same time. The light mixing cavity 6 is filled with a first light-transmitting medium 7 , the surface of the first light-transmitting medium 7 forms a zigzag microstructure, and the second light-transmitting medium 8 is covered thereon.

[0028] The white light emitted by the blue chip covered with the YAG phosphor layer and the red light emitted by the red LED chip 2 are fully mixed in the light mixing cavity 6 . The light sensor 3 detects the luminous...

Embodiment 2

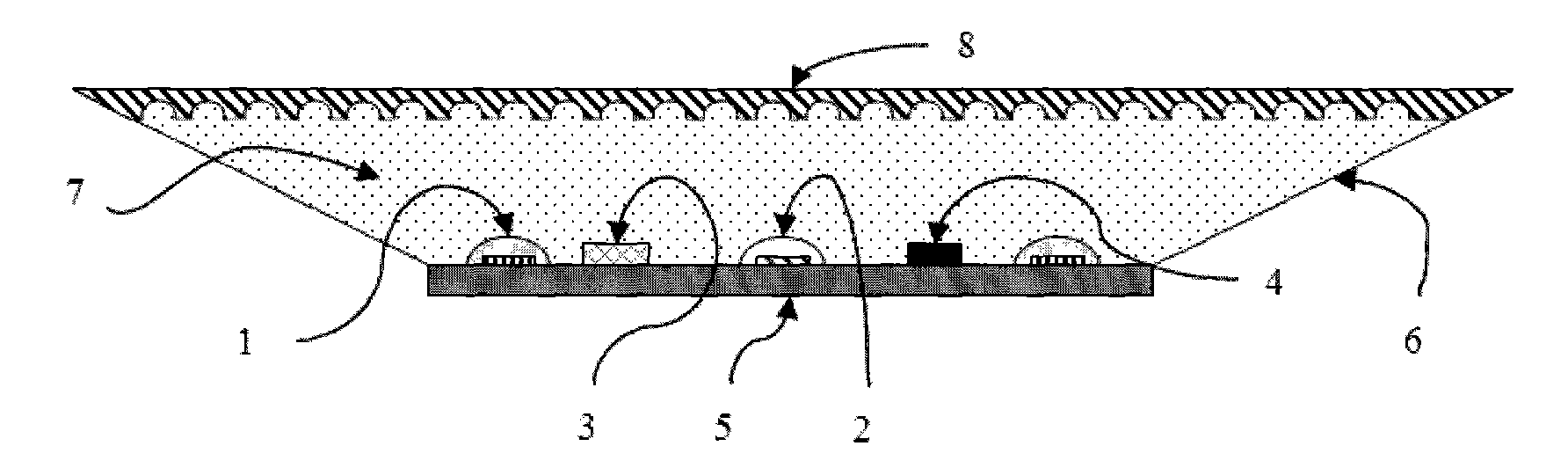

[0031] Such as figure 2 As shown, a highly stable red light enhanced color rendering LED light source module, the module substrate 5 is welded with a white LED chip 1 , a red LED chip 2 , a light sensor 3 and a temperature sensor 4 at the same time. Among them, the white LED1 and the red LED2 are packaged finished products and then integrated into the module. The interface between the first light-transmitting medium 7 and the second light-transmitting medium 8 is also made into a semicircle. Others are the same as in Example 1.

Embodiment 3

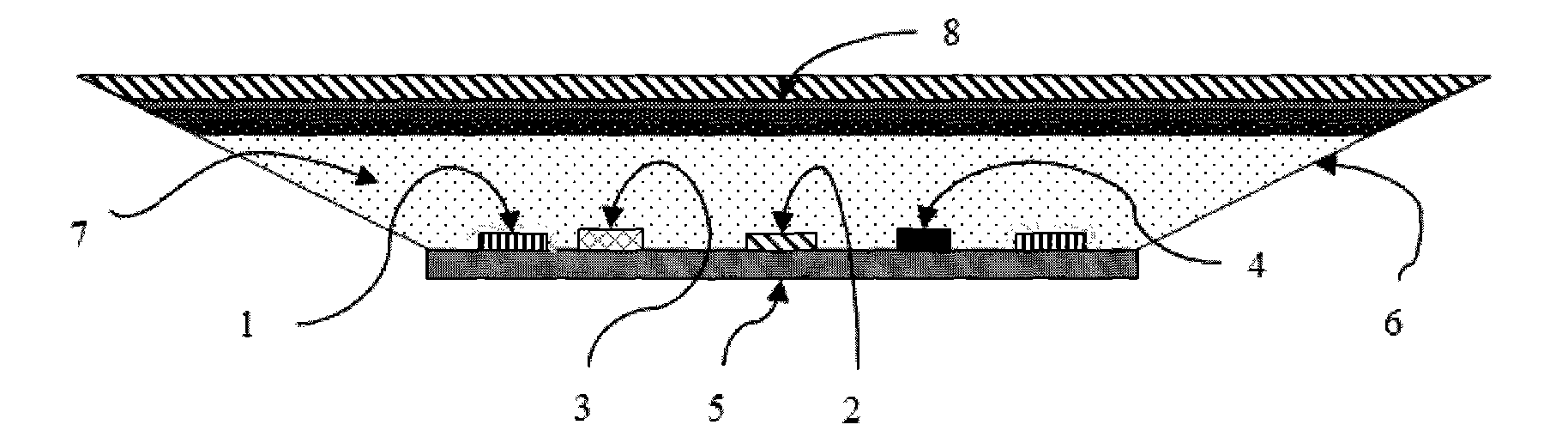

[0033] Such as image 3 As shown, the lower surface of the second light-transmitting medium 8 of the module is made of a multi-layer film structure, and the parameters of the multi-layer film should be set according to the red light wavelength and light transmittance that need to be enhanced. Others are then the same as in Example 1. The multi-layer film structure can achieve two important functions: 1. Improve the light extraction efficiency of the red light part and enhance the color rendering; 2. Prevent the influence of red light on the light sensor and improve the accuracy of light mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com