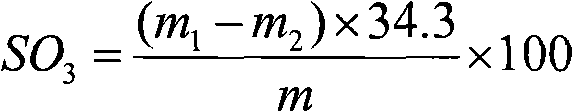

Method for determining sulfur trioxide content in coal ash

A technology of content and ashing, applied in the field of determination of sulfur trioxide content in coal ash, can solve the problems of high sulfur trioxide, which cannot represent the content of sulfur trioxide in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

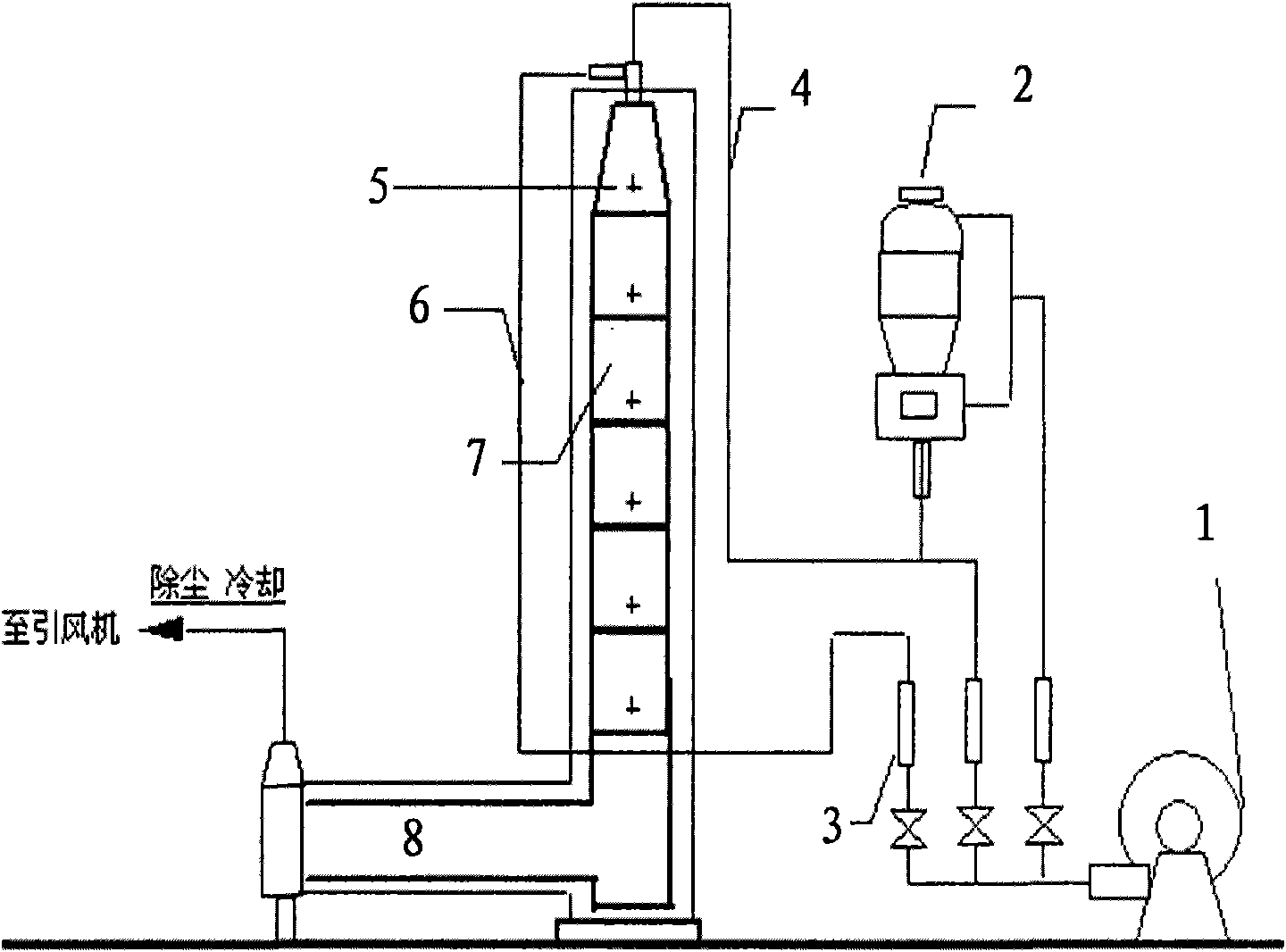

Method used

Image

Examples

Embodiment 1

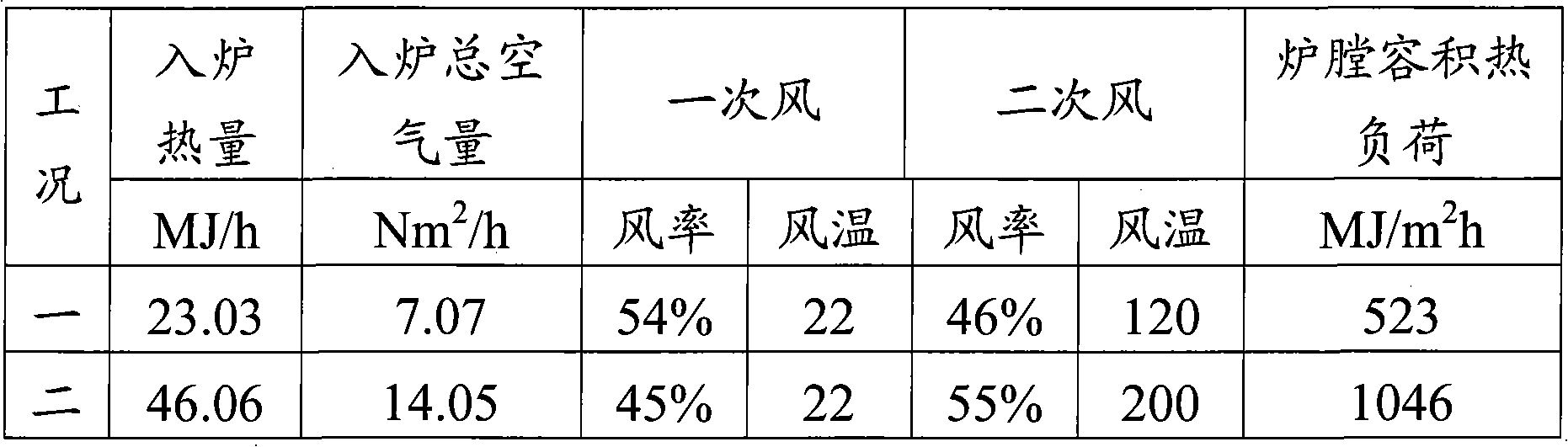

[0079] The method of the present invention is used to measure the content of sulfur trioxide in the coal ash of the following two coal samples.

[0080] Table 3. Performance parameters of coal sample 1 and coal sample 2

[0081] Test items

Coal sample 1

Coal sample 2

Total moisture (wt%)

16.6

17.4

Moisture on air dry basis (wt%)

5.59

10.09

Received base ash (wt%)

7.81

6.67

Volatile matter on dry ash-free basis (wt%)

35.51

34.34

Received base carbon (wt%)

60.34

60.79

[0082] Received base hydrogen (wt%)

3.69

3.58

Received base nitrogen (wt%)

0.83

0.74

Received base oxygen (wt%)

10.53

10.54

Received base total sulfur (wt%)

0.20

0.28

Received base high calorific value

(MJ / kg)

24.08

23.97

Received base low calorific value

(MJ / kg)

22.94 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com